Long-distance high-speed safe connecting rod

A long-distance, connecting rod technology, applied in the driving device of metal rolling mill, metal processing equipment, metal rolling, etc., can solve the problems of accelerated safety pin wear, hexagonal bolt breakage, gland bolt loosening, etc., to reduce The effect of downtime, economic loss and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

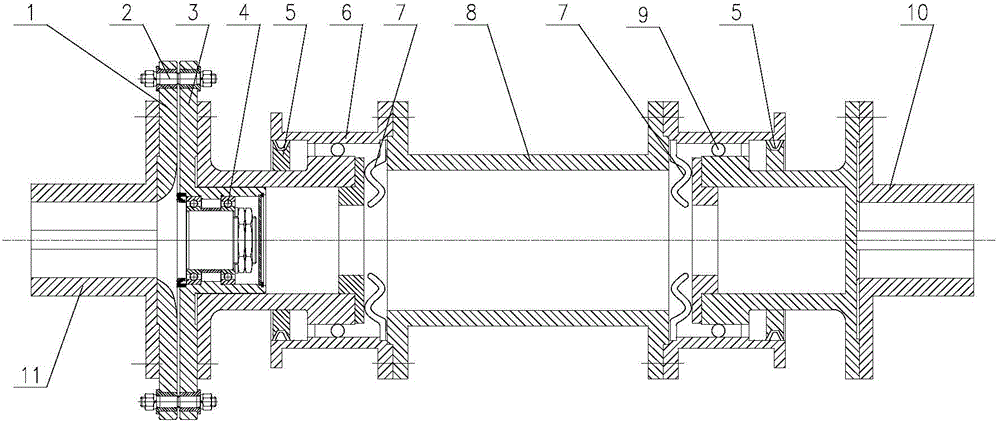

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0014] A long-distance high-speed safety connecting rod, which improves the structure of the drum-shaped tooth joint, cancels the original drum-shaped tooth joint and improves it into a ball coupling structure. Increase the inclination angle of the joints, reduce the neutral requirements for the motor and the reducer; improve the takeover gland and the sealing structure, change the original O-ring sealing structure to a Y-shaped lip seal, and improve the sealing ring's impact on the field transmission and swing angle. Adaptability, improve the sealing effect; improve the structure of the safety coupling, change the boss sleeve flange and the boss shaft flange into an integral structure, enhance the overall strength of the safety coupling, and at the same time make the safety coupling The original double-row tapered bearing inside the device is imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com