Lamp tube coding device and coding method

A lamp and coding machine technology, which is applied in the directions of typewriter, transportation and packaging, conveyor objects, etc., can solve the problem that the coding position of the lamp cannot be guaranteed to be uniform and fixed, so as to improve the leveling efficiency, facilitate control and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

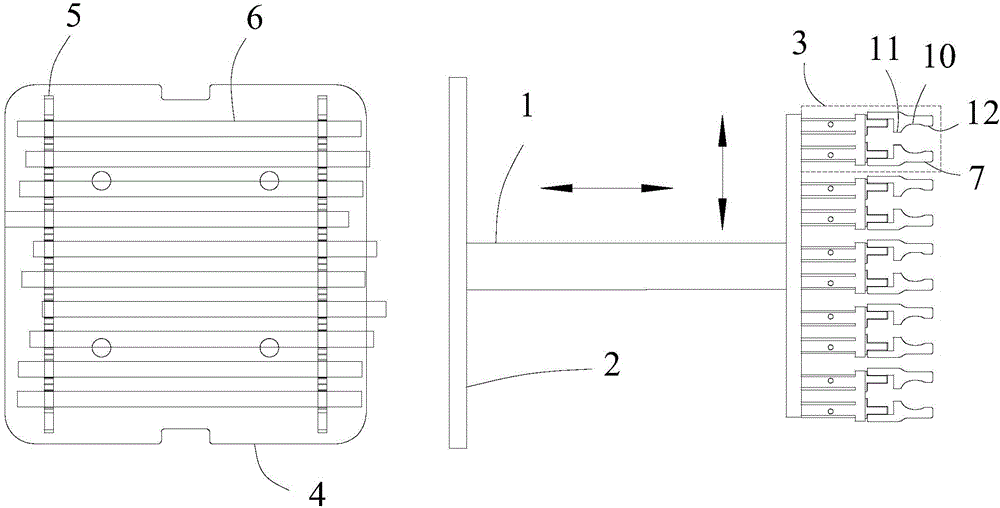

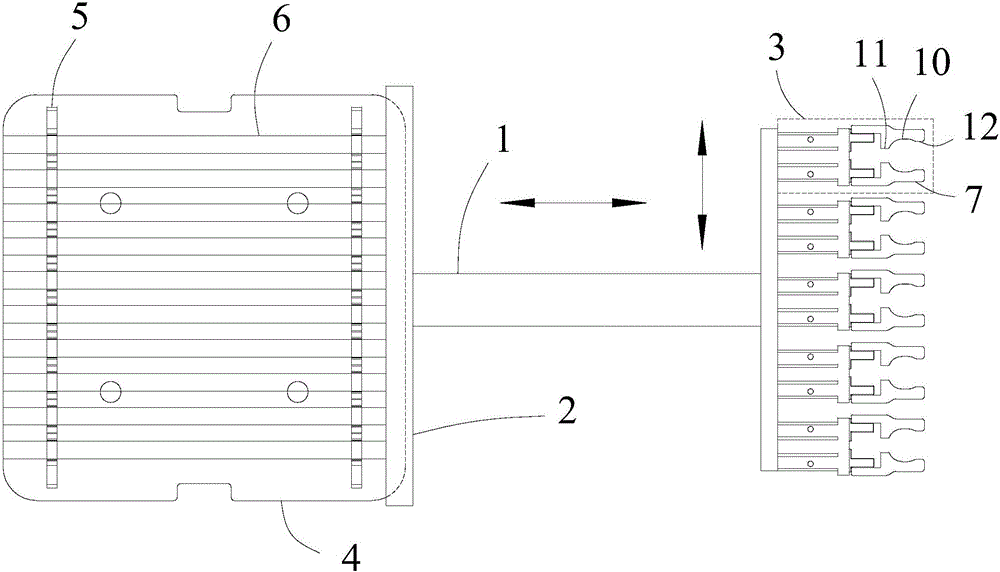

[0066] Such as figure 1 , a lamp coding device, comprising a lamp support part 4, a coding machine 8, a flattening part, and a lamp grabbing part, the lamp support part 4 is provided with two for placing the lamp 6 clamping pieces 5, two clamping pieces 5 are arranged oppositely on the lamp tube supporting part 4, the flattening part includes a moving part 1 and a flat plate 2 connected to one end thereof, and the flat plate 2 is opposite to the lamp tube 6. The axis is vertically arranged. The moving part 1 drives the flat plate 2 to perform reciprocating axial movement and lateral movement along the direction of the arrow in the figure. The other end of the moving part 1 is connected to the lamp grabbing part. Contains ten lamp tube clamps 3, two said lamp tube clamps 3 are arranged as a group facing each other. On a straight line, each of the lamp clamps 3 includes two opposite clamping arms 7, the size and shape of the two clamping arms 7 are the same, and the two clampin...

Embodiment 2

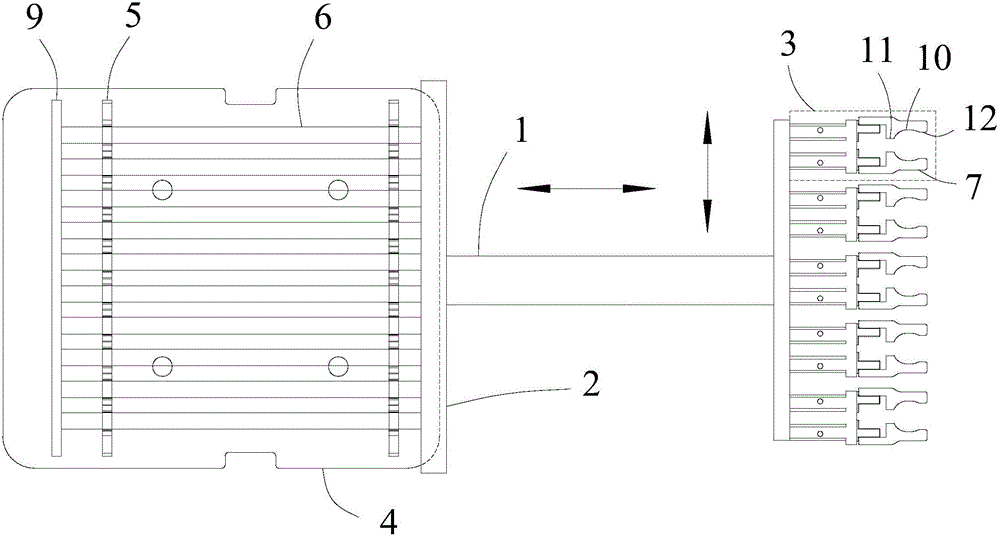

[0069] Specific as image 3 , a light tube coding device, the difference from Embodiment 1 is that a baffle 9 is provided on the outside of the clamping member on the opposite side of the flat plate, and the baffle 9 is perpendicular to the light tube, The height of the baffle plate 9 is higher than the height of the lamp tube 6, and the length matches the clamping member 5. In the initial state, several of the lamp tubes 6 are not aligned. When the moving part 1 drives the plate 2. After the lamp tube 6 is pushed to move for a certain distance, the baffle plate 9 restricts the lamp tube 6 from continuing to move. At this time, both ends of the lamp tube 6 are flush to prevent the pushed end from falling due to the push. At the same time, it can also reduce the error caused by the inertia when pushing to stop, effectively save the pushing distance, improve the leveling efficiency, save costs, increase safety, and then improve the production efficiency of the entire assembly li...

Embodiment 3

[0072] A coding method for a lamp coding device, comprising using a lamp coding device as in embodiment 1 or 2, the method of use comprising the following steps:

[0073] Step 1. Use the moving part 1 to drive the flat plate 2 to move to the side of the end of the light tube, perpendicular to the light tubes 6 , and the position of the flat plate 2 is compatible with all the light tubes 6 .

[0074] Step 2: Use the moving part 1 to drive the flat plate 2 to push along the axial direction of the lamp tubes 6, and stop after pushing a suitable distance, so that the ends of all the lamp tubes 6 are aligned.

[0075] Step 3: grab the lamp tube 6 with the lamp tube chuck 3 on the lamp tube grabbing part.

[0076] Step 4: Use the lamp tube chuck 3 on the lamp tube grabbing part to move to the coding machine 8 for coding respectively until all the lamp tubes 6 are coded.

[0077] After all the lamp tubes are flattened, grab and move to the coding machine 8 to code, ensuring that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com