A passenger car beam assembly

A beam assembly and longitudinal beam assembly technology, which is applied to the upper structure of passenger cars, vehicle components, load-bearing body structures, etc., to achieve the effects of strong versatility, shortened production cycle, and reduced welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

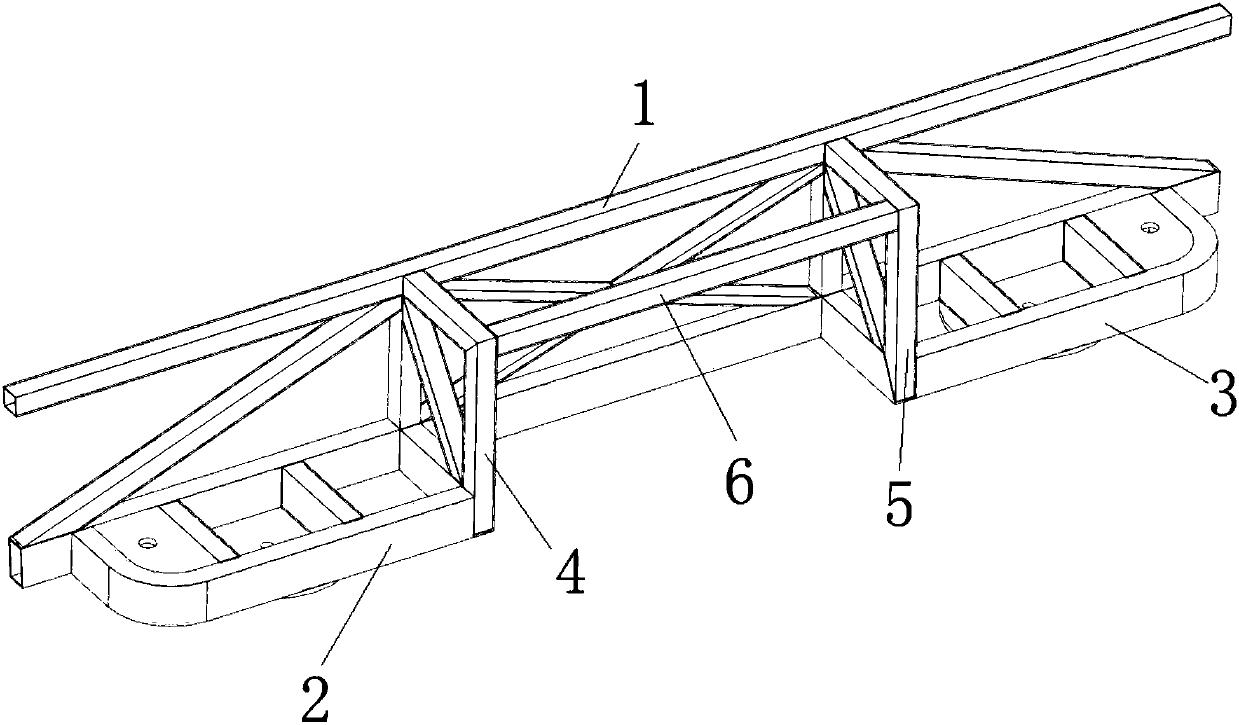

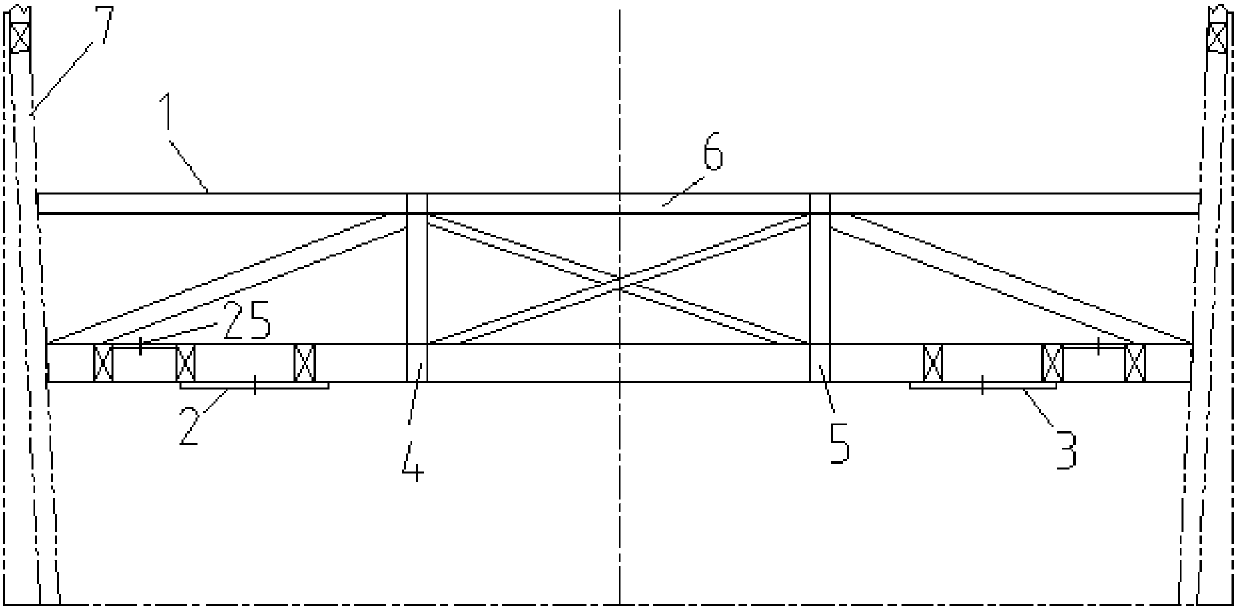

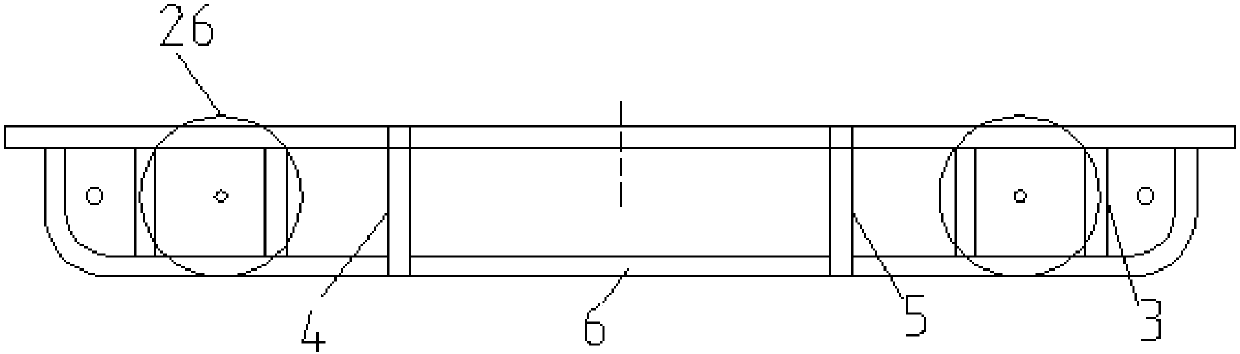

[0024] Such as Figure 1-Figure 3 The shown cross beam assembly for a passenger car includes a front section beam assembly 1, a left connecting longitudinal beam assembly 2 and a right connecting longitudinal beam assembly 3 arranged symmetrically on the rear sides of the left and right ends of the middle section of the front section beam assembly 1, And the left rear airbag support assembly 4 and the right rear airbag support assembly 5 which are symmetrically arranged on the rear sides of the left and right ends of the front section beam assembly 1 . A third reinforcing crossbeam 6 is connected between the upper end rear part of the left connecting longitudinal beam assembly 2 and the upper end rear part of the right connecting longitudinal beam assembly 3, to ensure the lateral stability of the entire crossbeam assembly, and the third strengthening The space formed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com