Water-white rosin production line

A water-white rosin and production line technology, which is applied in the field of resin deep processing, can solve problems such as other reactions that easily occur and affect product quality, and achieve the effects of quality assurance, production efficiency assurance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the implementation of the drawings:

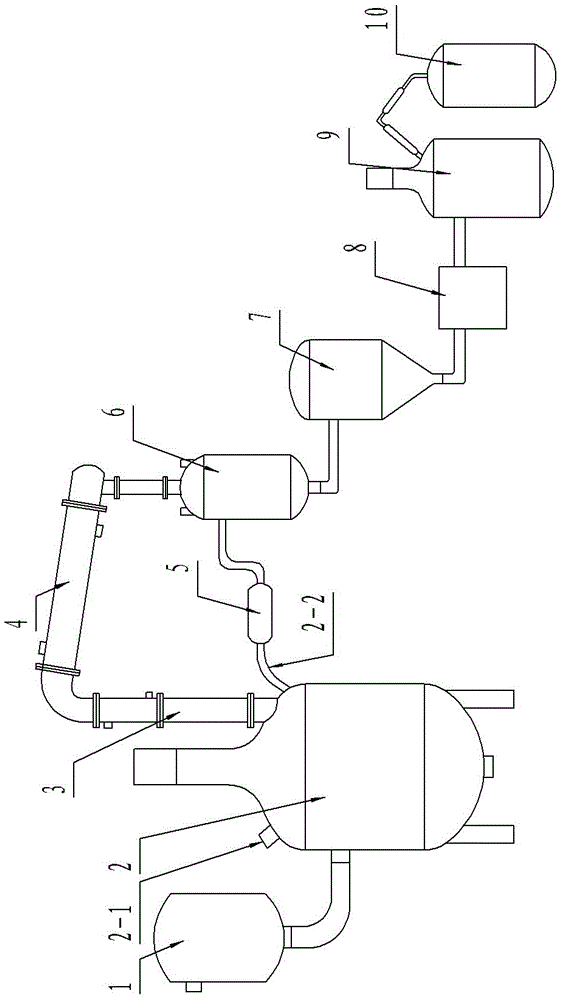

[0012] Such as figure 1 The water white rosin production line shown includes a preheating pot 1, the preheating pot 1 is connected to a hydrogenation reactor 2, the upper part of the reactor 2 is vertically connected with a vertical condenser 3, and the top of the vertical condenser 3 is inclined to The lower ground is connected with a horizontal condenser 4, the reactor 2 has a nitrogen inlet 2-1, and the reactor 2 is equipped with a nitrogen return pipe 2-2. The horizontal condenser 4 is connected to the clarification pot 7 through a vapor-liquid separator 6. The liquid separator 6 is connected to the uppermost end of the nitrogen return pipe 2-2. Nitrogen can be added during the reaction and cooling process to protect the fraction from other reactions and not reduce the purity of the fraction to ensure product quality. There is a backflow compensato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com