Sponge city construction groundwater recharge well and rapid well formation method thereof

A technology of sponge city and recharge well, which is applied in construction, waterway system, sewage removal, etc., can solve the problems of high cost, long time, complicated construction, etc., and achieve the effect of convenient backfill and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

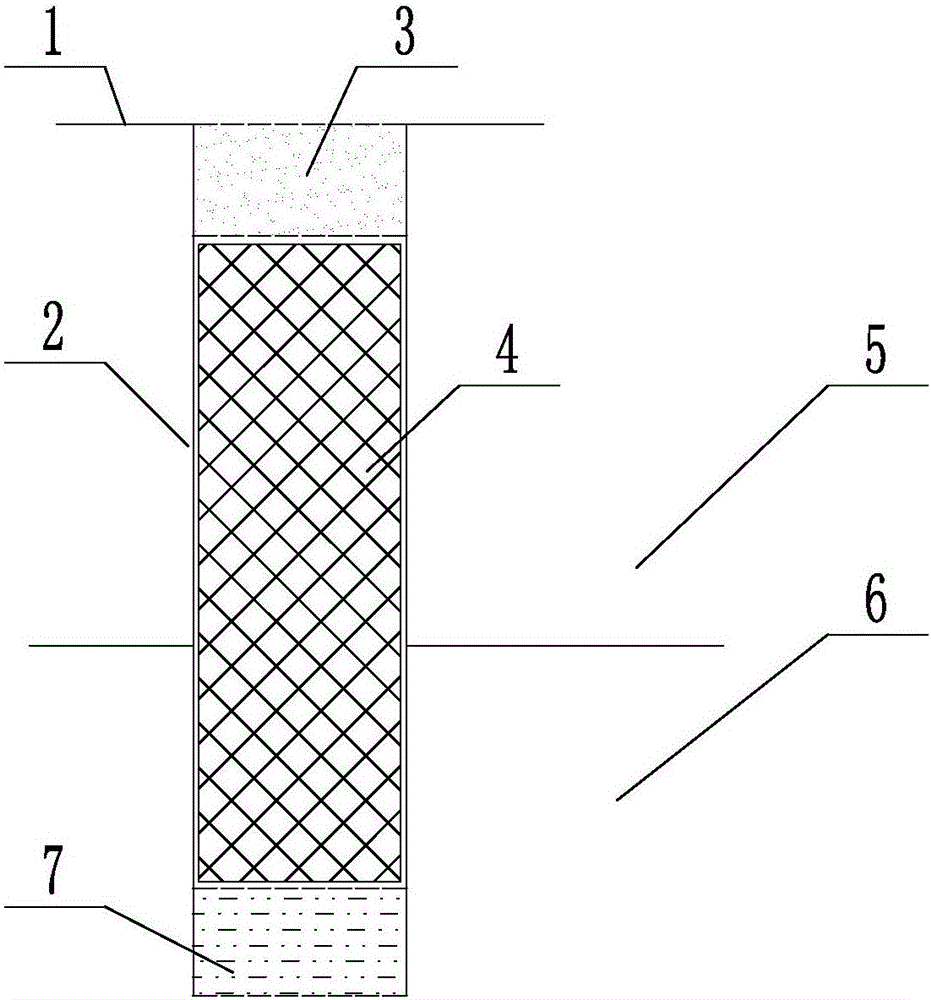

[0033] Such as figure 1 and figure 2 As shown, the sponge city construction groundwater recharge well includes a borehole 2, and the borehole 2 can be arranged on the roadside, lawn, parking lot, below the permeable road surface, in a community or in a unit courtyard, etc., and can also be used in infiltration ponds, For internal use in seepage wells, wet ponds, rainwater wetlands, etc.

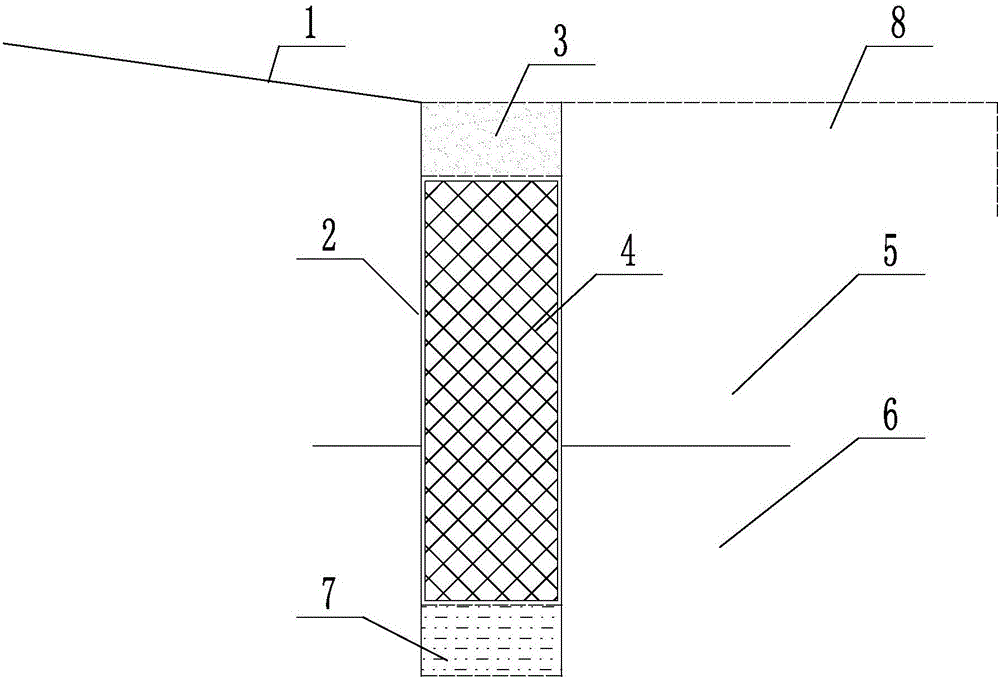

[0034] Such as figure 2 Said, the borehole 2 is set on the road surface 1 close to the lawn 8 or in the lawn 8 . The road surface 1 can be a road surface with a common cross slope of 1.5%-2% in urban construction, and can be further optimized to a road surface 1 with a slope of 3%-5%, without changing the original road structure. When precipitation occurs, Rain (or snowmelt) water will quickly flow into the borehole 2 along the slightly inclined road surface 1 .

[0035] After the borehole 2 cuts through the aquifer 5 to the water-bearing sand layer 6 to form a well, first lay a 20-30cm...

no. 2 example

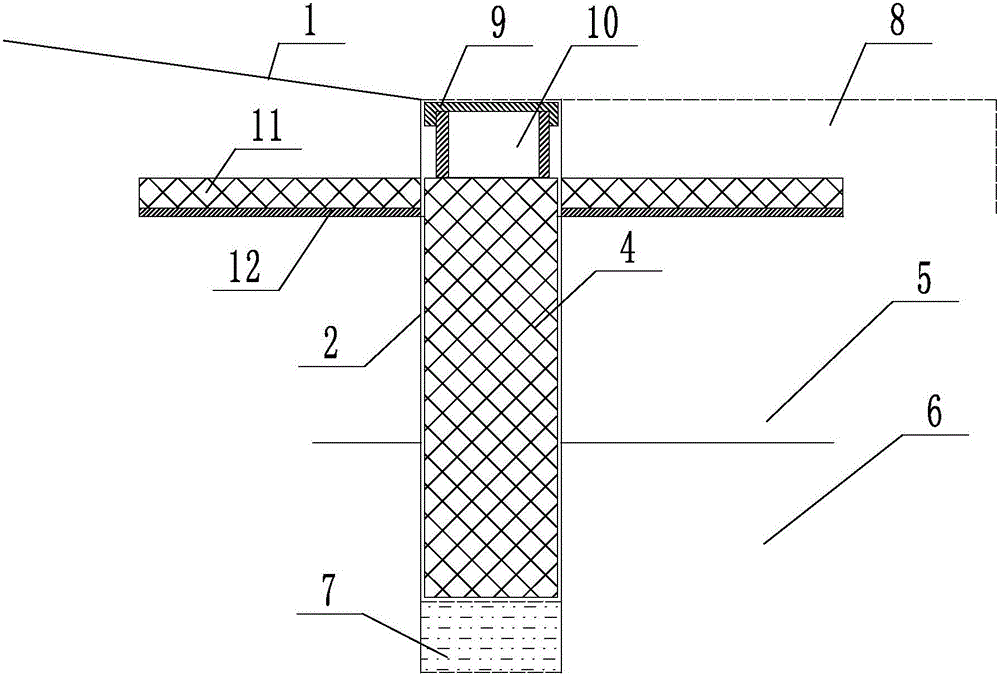

[0043] Such as image 3 and Figure 4 As shown, the difference from the first embodiment is that a wellhead connection device is added, and the wellhead connection device includes a reinjection well joint 10 , a water-permeable reinjection well cover 9 , a sponge strip 11 and a connecting channel 12 . A recharge well joint 10 is arranged on the top of the hard sponge 4, and a permeable recharge well cover 9 is screw-mounted on the recharge well joint 10, and the well cover is slightly higher than the ground. This design can avoid the problem of initial rainwater pollution. , the clean rainwater in the later stage can infiltrate through the permeable recharge manhole cover 9 with osmosis.

[0044] One side of the hard sponge 4 is provided with a connecting channel 12, such as Figure 4 Said, several connecting passages 12 are provided on the periphery of the hard sponge, and the connecting passages 12 can be U-shaped grooves, arc-shaped grooves, or other grooves with communic...

no. 3 example

[0047] Such as Figure 5 As shown, the difference from the first embodiment is that a curbstone 13 is arranged above the hard sponge 4, and an L-shaped channel for rainwater diversion is arranged in the curbstone.

[0048] A more optimal design is provided with a sand filter layer between the hard sponge and the roadside stone.

[0049] This design can be retrofitted without destroying the existing roads, with low cost and good rainwater infiltration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com