Dismountable assembly type circular steel tube concrete column

A technology of concrete columns and round steel pipes, applied to columns, pier columns, pillars, etc., can solve the problems of lack of systematic research on design methods of key connection parts, low recycling rate of building materials, high material and energy consumption, and achieve installation Convenient and efficient, reducing welding work and form work, and ensuring the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The assembly construction steps of the above circular steel pipe concrete columns are as follows:

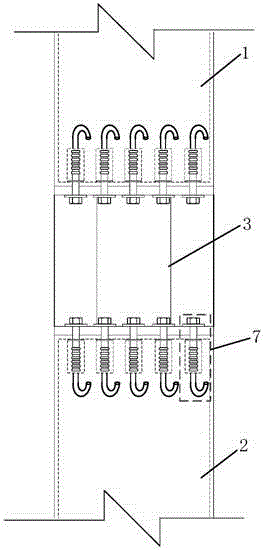

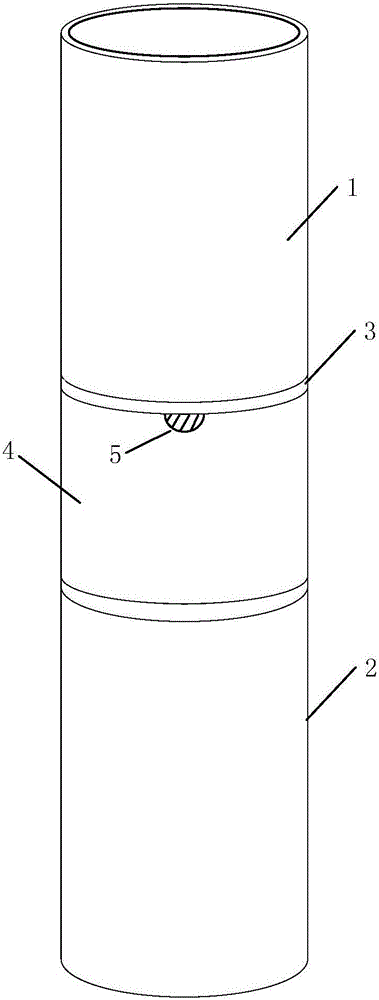

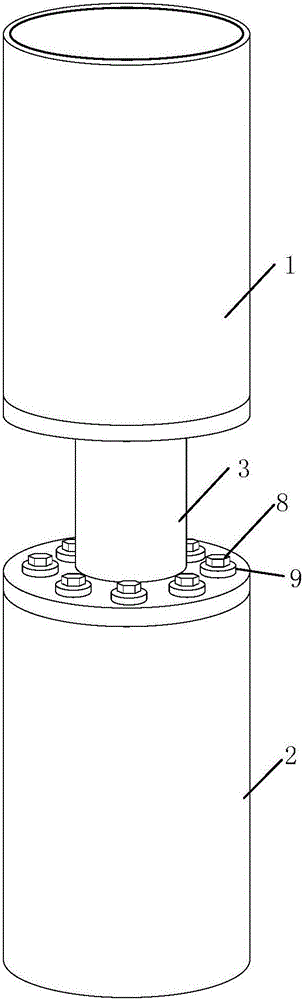

[0024] 1. In addition to grouting the reserved holes of the semi-circular steel plate at the joint between columns, all components are prefabricated in the factory, and the size and spacing of bolt holes reserved on the column flange connector 3 should meet construction requirements. The embedded steel sleeves 10 inside the upper and lower round concrete-filled steel tube columns 1 and 2 should correspond to and be matched with the bolt holes 6 reserved on the column flange connector 3 ( image 3 with Figure 4 shown);

[0025] 2. Place the column flange connector 3 on the surface of the steel sleeve 10 reserved for the lower circular steel pipe concrete column 2, so that the reserved bolt holes 6 on the column flange connector 3 are aligned with the holes in the steel sleeve 10, and install 6 pairs of bolt rods 8 and gaskets 9 to complete the splicing of the lower cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com