Pipeline pressure stabilization system and method after a liquefied petroleum gas pipeline is shut down

A liquefied petroleum gas and pipeline technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of medium phase change in the pipeline, consume manpower and material resources, and difficult to establish a back pressure system to achieve safety Good, the effect of increasing system pressure and stabilizing system pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

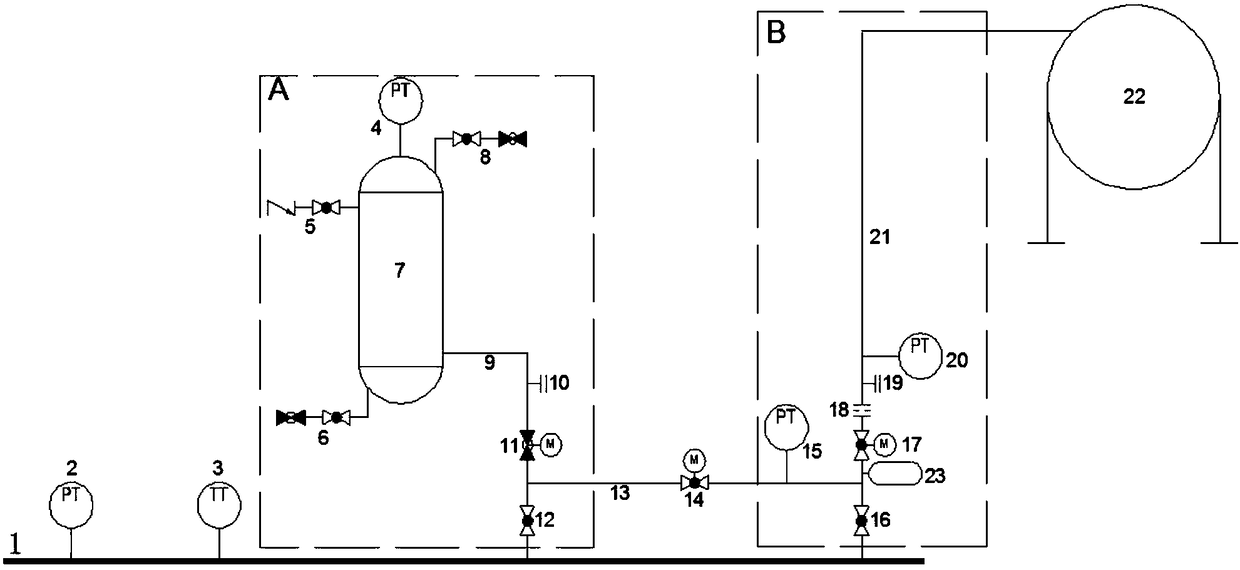

[0019] A pipeline pressure stabilization system after the liquefied petroleum gas pipeline is shut down, such as figure 1 As shown, it includes: main pipe joint 1, first pressure transmitter 2, temperature transmitter 3, second pressure transmitter 4, gas injection valve group 5, liquid discharge valve group 6, pressure buffer tank 7, exhaust Air valve group 8, discharge branch pipe 9, purge discharge port 10, stop valve 11, first shut-off valve 12, connecting branch pipe 13, second shut-off valve 14, third pressure transmitter 15, third shut-off valve 16 , the fourth cut-off valve 17, the flow-restricting orifice 18, the purge port 19, the fourth pressure transmitter 20, the built liquefied petroleum gas storage tank 22 and the pressure buffer 23, etc., wherein:

[0020] Second pressure transmitter 4, gas injection valve group 5, liquid discharge valve group 6, pressure buffer tank 7, exhaust valve group 8, discharge branch pipe 9, purge liquid discharge port 10, stop valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com