Graphene surface plasmon polariton (SPP) propagation device of periodic grating structure

A graphene surface, grating structure technology, applied in the field of optical communication, can solve the problems of reducing graphene carrier mobility, low quality factor, SPP propagation distance, and reducing the degree of localization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

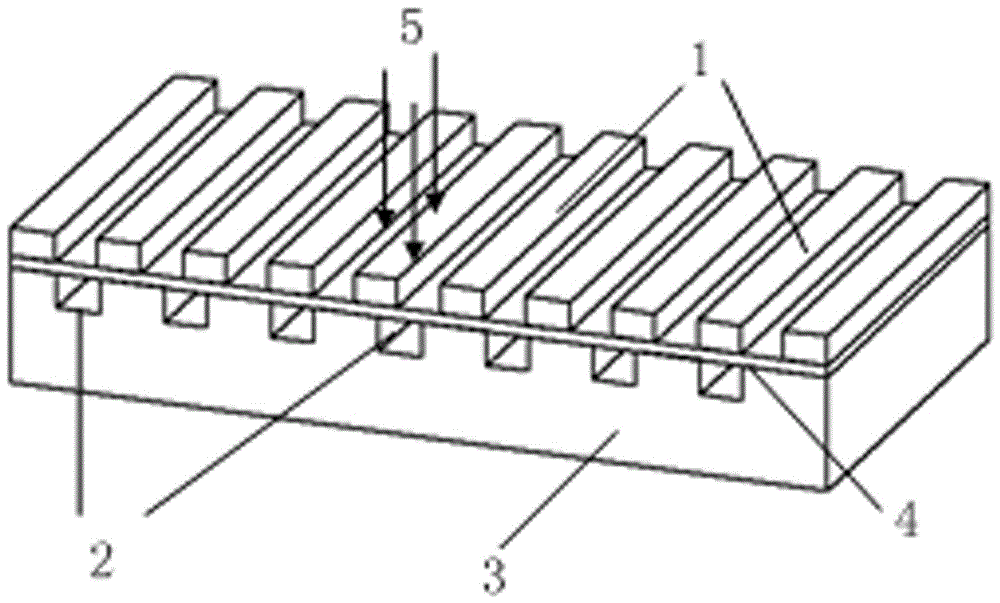

[0022] refer to figure 1 , a graphene surface plasmon propagation device with a periodic grating structure, comprising

[0023] A silicon dioxide base layer 3, the upper surface of the silicon dioxide base layer 3 is etched with a periodic grating structure 2; the ridge of the periodic grating structure 2 is provided with an organic dye gain medium 4;

[0024] Graphene layer, the graphene layer is the graphene layer 1 of array nanoribbon structure;

[0025] The upper surface of the silicon dioxide base layer 3 is overlapped with the graphene layer 1 of the nanoribbon array structure.

[0026] The silicon dioxide base layer 3 is an insulating layer.

[0027] Controlling the grating period of the periodic grating structure 2 and the width of the nanoribbons in the graphene layer 1 adjusts the SPP resonance frequency.

[0028] The incident light 5 is p-polarized light vertically irradiating the graphene waveguide on the graphene layer 1 of the array nanoribbon structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com