Method for improving binding power of submarine cable insulating layer and copper tube

A technology of insulating layer and adhesive force, applied in the direction of optical fiber/cable installation, optics, light guide, etc., can solve the problems of PE sheath pull-off, submarine cable damage, etc., to achieve tight adhesion, improve adhesion, enhance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

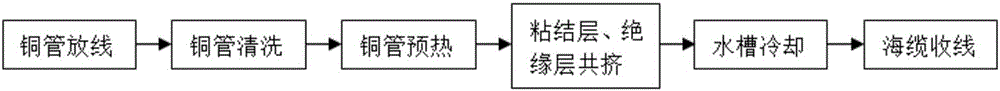

[0031] refer to figure 1 As shown, a method for promoting the bonding force between the submarine cable insulation layer and the copper pipe is disclosed in Embodiment 1, and the method has the following steps:

[0032] Step 1, uniformly mixing ethylene acrylic acid copolymer and polyethylene to obtain a bonding material, wherein the above-mentioned ethylene acrylic acid copolymer accounts for 10% by mass of the bonding material, and the above-mentioned polyethylene accounts for 90% by mass of the bonding material;

[0033] Step 2, preparing polyethylene material as the insulating layer material;

[0034] Step 3. Dry the bonding material prepared in step 1 and the insulating material prepared in step 2 with a drying machine for 2 hours, and then preheat the single-screw extruder to 160°C;

[0035] Step 4. Copper tube is unwound. Before the copper tube enters the extruder die, it is cleaned with alcohol, and the copper tube is preheated with a preheater. After preheating, the ...

Embodiment 2

[0039] Embodiment 2 discloses a method for improving the bonding force between the insulating layer of the submarine cable and the copper pipe, which mainly includes the following steps:

[0040] Step 1. Uniformly mixing ethylene acrylic acid copolymer and polyethylene to obtain a bonding material, wherein the above-mentioned ethylene acrylic acid copolymer accounts for 55% by mass of the bonding material, and the above-mentioned polyethylene accounts for 45% by mass of the bonding material;

[0041] Step 2, preparing polyethylene material as the insulating layer material;

[0042] Step 3. Dry the bonding material prepared in step 1 and the insulating material prepared in step 2 with a drying machine for 3 hours, and then preheat the single-screw extruder to 225°C;

[0043] Step 4. Copper pipe is unwound. Before the copper pipe enters the extruder die, it is cleaned with alcohol, and the preheater is used to preheat the copper pipe. After preheating, the surface temperature of...

Embodiment 3

[0047] Embodiment 3 discloses a method for improving the bonding force between the insulating layer of the submarine cable and the copper pipe, which mainly includes the following steps:

[0048] Step 1, using 100% ethylene acrylic acid copolymer (EAA) as the bonding material in mass percentage;

[0049] Step 2, preparing polyethylene material as the insulating layer material;

[0050] Step 3. Dry the bonding material prepared in step 1 and the insulating material prepared in step 2 with a drying machine for 4 hours, and then preheat the single-screw extruder to 290°C;

[0051] Step 4. Copper tube is unwound. Before the copper tube enters the extruder die, it is cleaned with alcohol, and the copper tube is preheated with a preheater. After preheating, the surface temperature of the copper tube is 200°C;

[0052] Step 5. The single-screw extruder adopts a double-layer co-extrusion mode to extrude a layer of bonding layer and an insulating layer on the surface of the copper pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com