A Method of Temperature Compensation for CNC Machine Tool Based on Error Adaptation

A CNC machine tool and temperature compensation technology, applied in the field of machine tools, can solve problems such as difficult maintenance and replacement, affecting the work of machine tools, etc., to achieve the effects of ensuring machining accuracy, avoiding redundant work, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

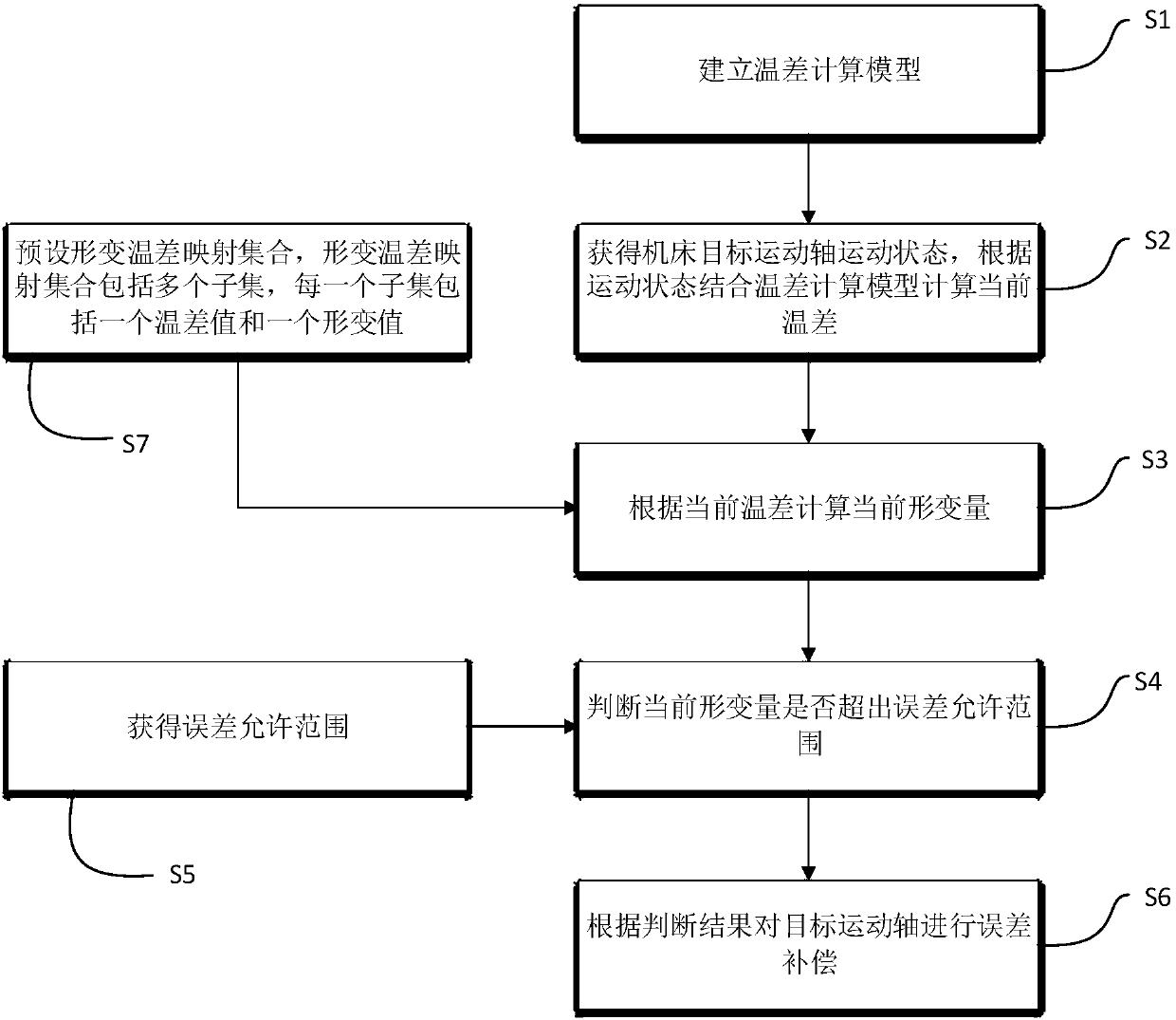

[0023] refer to figure 1 , a method for temperature compensation of a CNC machine tool based on error adaptation proposed by the present invention includes the following steps.

[0024] S1. Establish a temperature difference calculation model.

[0025] In this embodiment, the temperature difference calculation model can be obtained by pre-installing a temperature sensor on the machine tool of the same model, and then obtaining the temperature difference in various motion states through the temperature sensor, and calculating the temperature difference calculation model according to the corresponding relationship between the motion state and the temperature difference .

[0026] The temperature difference calculation model is: Among them, T i is the current temperature difference, T i-1 is the temperature difference at the latest speed change of the moving shaft, V i is the current movement speed of the movement axis, V i-1 is the movement speed of the movement axis befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com