A kind of encapsulation method and encapsulation structure of high-power LED

A technology of LED packaging and packaging method, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the power of LED chips restricting the service life of high-power LEDs, reducing the luminous efficiency of LED chips, and reducing the conversion efficiency of phosphors, etc. Achieve the effect of prolonging the service life, improving the fluorescence conversion efficiency, and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

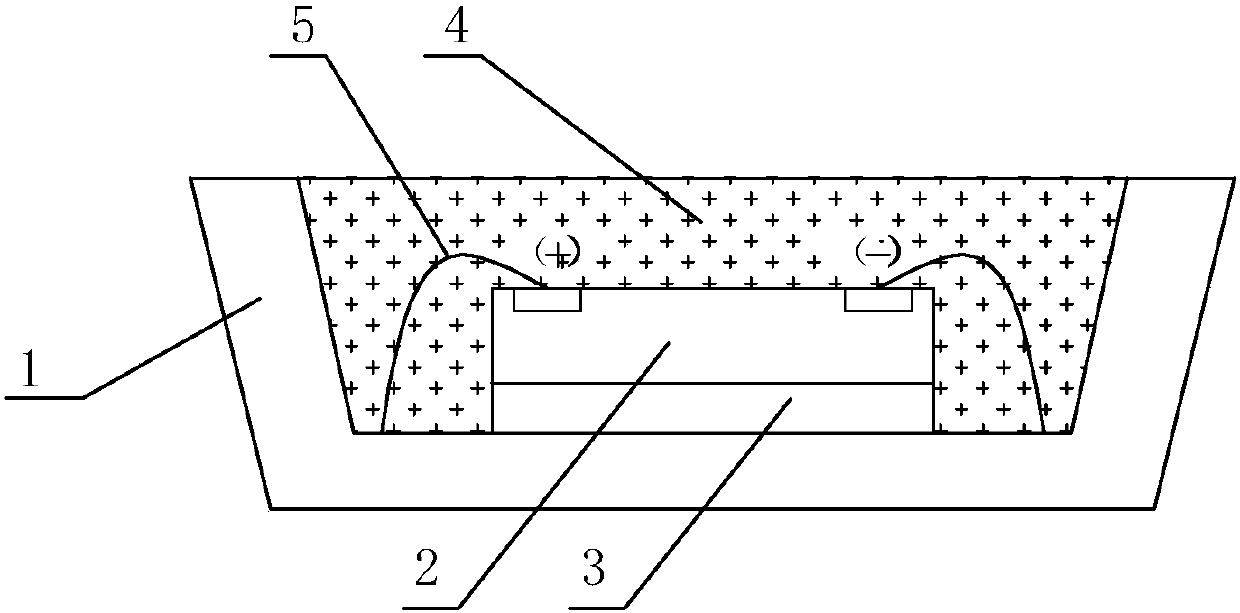

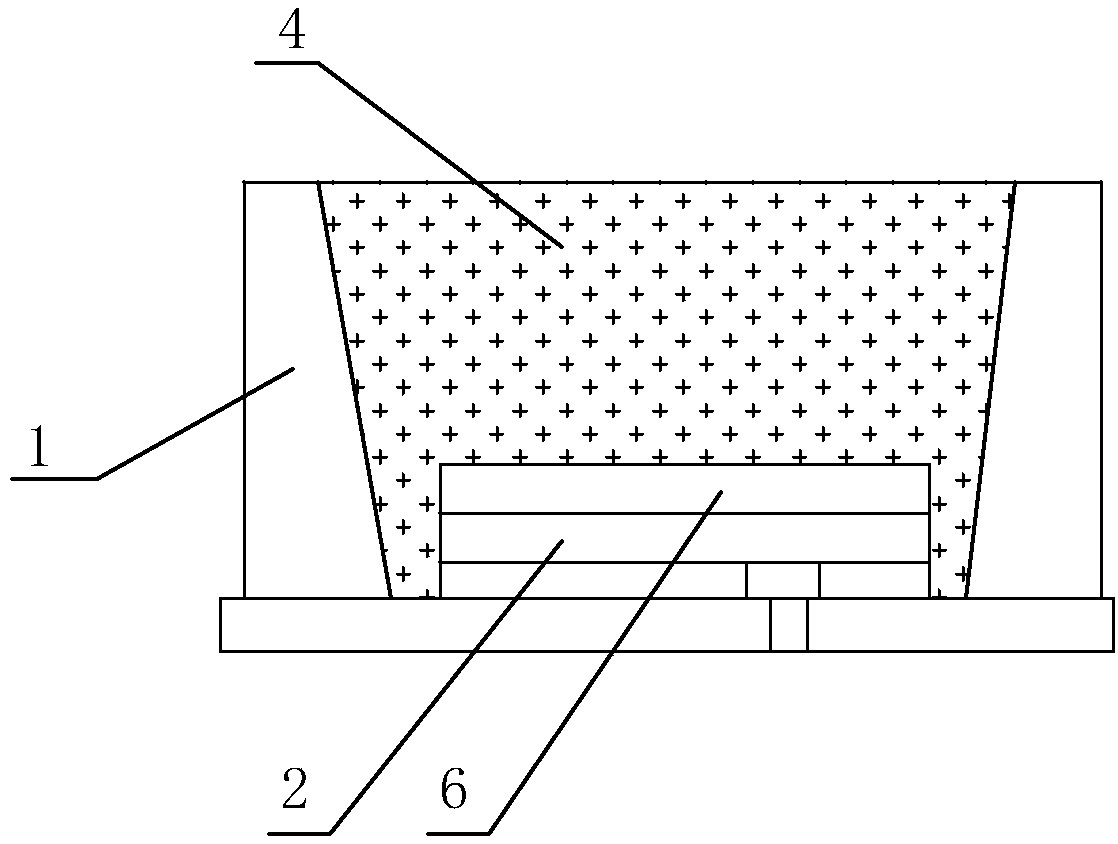

[0040] The technical solution of the present invention provides a high-power LED packaging method, the LED at least includes an LED chip arranged in a bracket or on a substrate (hereinafter referred to as a bracket) (for brevity, hereinafter referred to as image 3 LED Flip Chip in and Figure 4The formally installed LED chips are referred to as LED chips for short), and its invention points are:

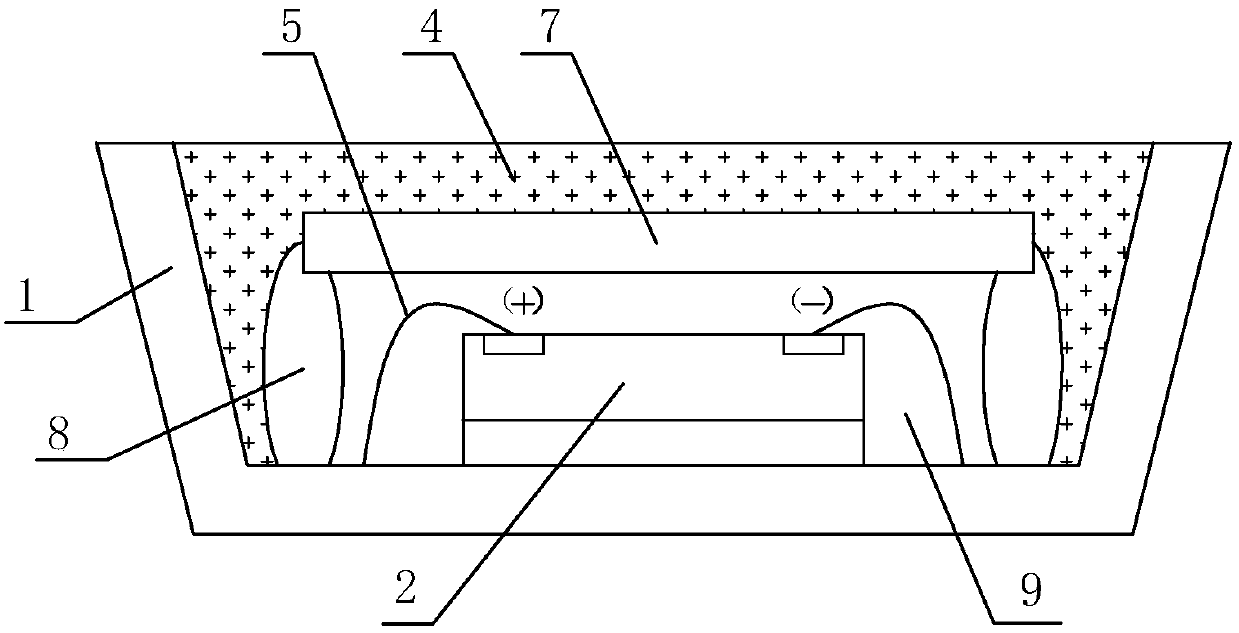

[0041] Above the LED chip 2, a solid light-transmitting heat-conducting window layer 7 is arranged;

[0042] Around the LED chip, a dam 8 is set;

[0043] By setting the dam structure, the solid light-transmitting heat-conducting window layer is used as the upper base, the bracket 1 is used as the lower base, and the dam is used as the side to form a heat-conducting cavity around the LED chip. 9;

[0044] In the high-power LED packaging method, by setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com