Single large-capacity polymer lithium-ion battery manufacturing method and assembling method thereof

A lithium-ion battery and polymer technology, applied in secondary battery manufacturing, battery pack components, secondary batteries, etc., can solve the problem that the diaphragm is not easy to flatten, and achieve the effect of realizing large capacity and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

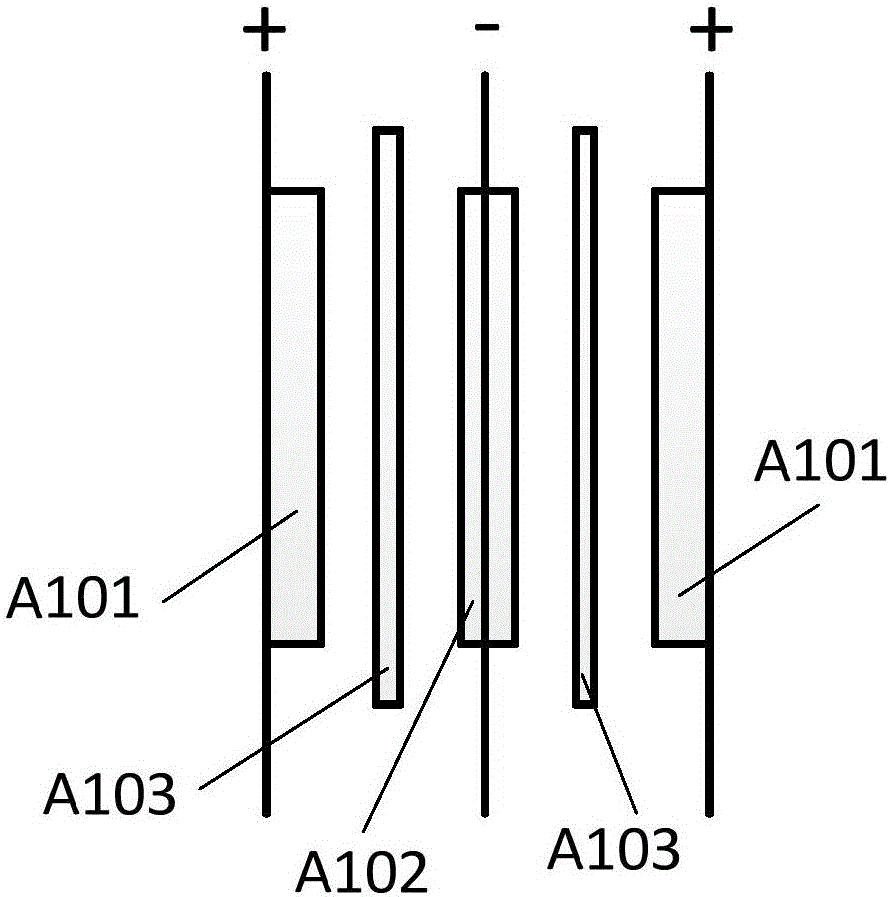

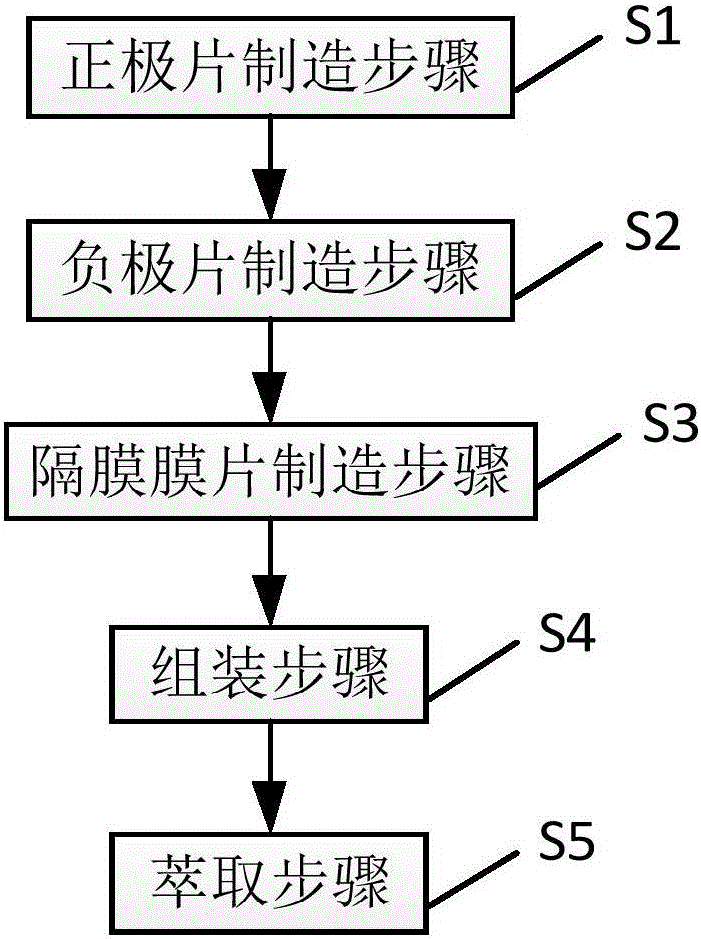

[0037] Please refer to figure 2 , the present embodiment provides a method for manufacturing a monomer high-capacity polymer lithium-ion battery, comprising the following steps:

[0038] S1: a positive electrode sheet manufacturing step, used to prepare the positive electrode sheet.

[0039] S2: a negative electrode sheet manufacturing step, for preparing the negative electrode sheet.

[0040] S3: The diaphragm membrane manufacturing step, which is used to coat the prepared diaphragm slurry on the polyester film to prepare the diaphragm membrane.

[0041] S4: Assembly step.

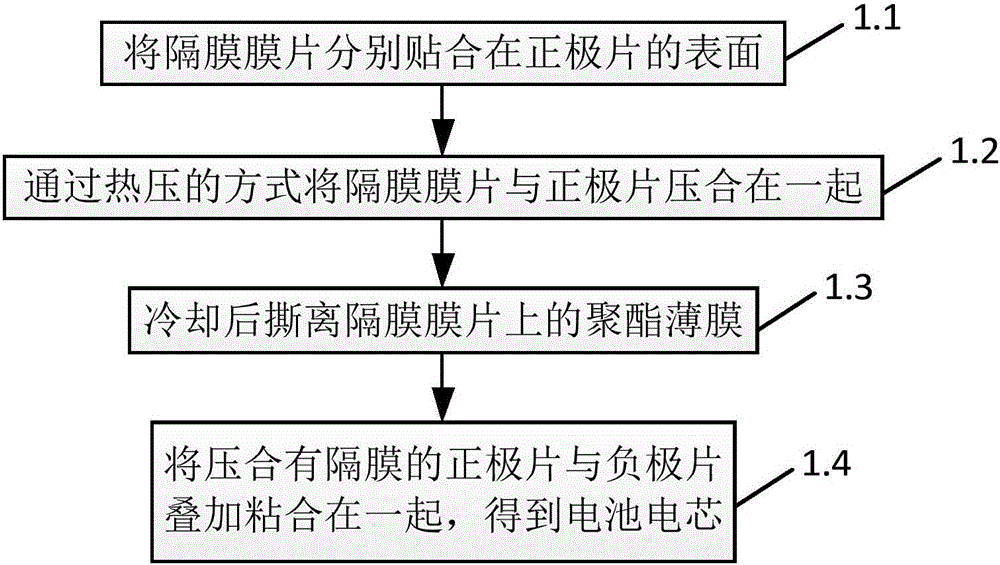

[0042] Please refer to image 3 , the assembly step (S4) includes the following sub-steps:

[0043] S1.1: Lay the diaphragm membranes on the surface of the positive electrode sheet respectively.

[0044] S1.2: Press the diaphragm and the positive electrode together by hot pressing. In this embodiment, a temperature of 100-140° C. and a pressure of 1-20T (for example, 10T) can be used to press the d...

Embodiment 2

[0053] Please refer to Figure 4, The present embodiment also provides a method for manufacturing a positive electrode sheet of a monomer large-capacity polymer lithium-ion battery (ie, the positive electrode sheet manufacturing step S1 in the first embodiment above), which includes the following steps:

[0054] Step 2.1: preparing a current collector and a current collector treatment slurry, the current collector treatment slurry at least includes a conductive agent. Usually, aluminum foil is used as the positive electrode current collector.

[0055] Step 2.2: Coating the current collector treatment slurry on the surface of the current collector.

[0056] Step 2.3: preparing positive electrode slurry, the positive electrode slurry at least includes positive electrode active material, conductive agent and positive electrode polymer. Among them, lithium cobalt oxide, lithium iron phosphate, lithium nickel cobalt manganate, lithium nickel cobalt aluminate, lithium manganate, l...

Embodiment 3

[0075] Please refer to Figure 7 , The present embodiment also provides a method for manufacturing a negative electrode sheet of a monomer large-capacity polymer lithium-ion battery (ie, the negative electrode sheet manufacturing step S2 in the first embodiment above), which includes the following steps:

[0076] Step 3.1: preparing a current collector and a current collector treatment slurry, the current collector treatment slurry at least includes a conductive agent. Usually, copper foil is used as the negative electrode current collector.

[0077] Step 3.2: Coating the current collector treatment slurry on the surface of the current collector.

[0078] Step 3.3: preparing negative electrode slurry, the negative electrode slurry at least includes negative electrode active material, conductive agent and negative electrode polymer. Among them, the negative electrode active material can be carbon materials such as artificial graphite, natural graphite, hard carbon, mesocarbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com