Manufacture method of paeonia suffruticosa and paeonia lactiflora dried flowers

A production method and technology of peony flowers, applied in the direction of botanical equipment and methods, application, plant preservation, etc., can solve problems such as rot, difficult dehydration, and many layers of peony petals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

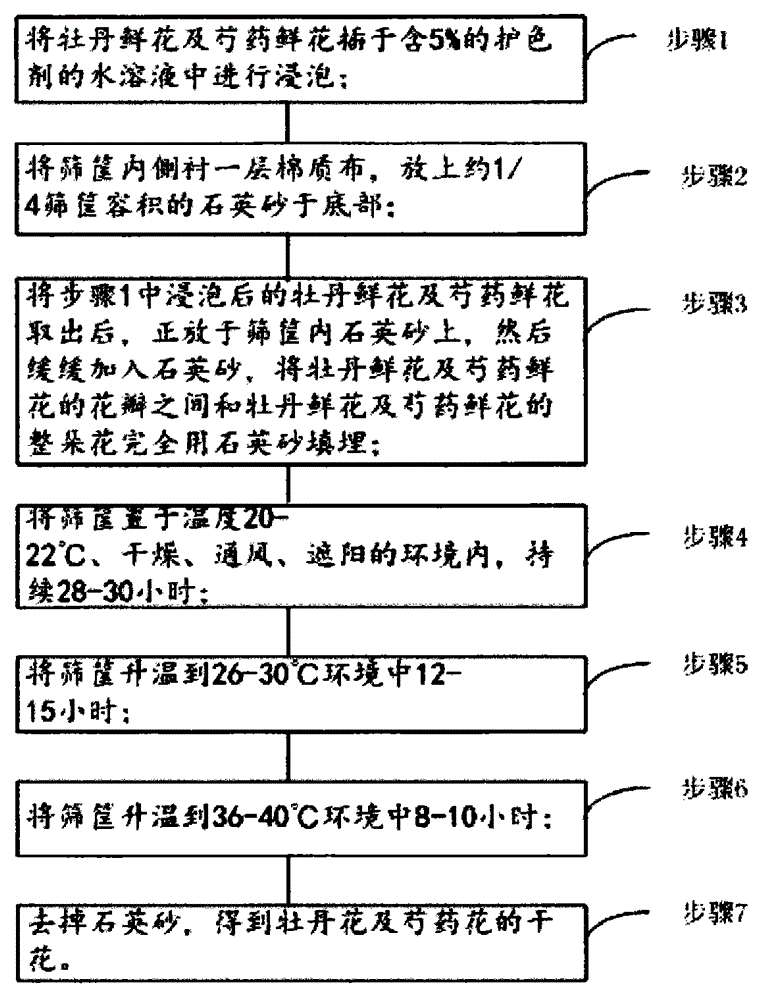

[0025] Such as figure 1 Shown, the present invention provides a kind of peony and peony dried flower preparation method, comprise the following steps:

[0026] Step 1: soak peony flowers and peony flowers in an aqueous solution containing 5% color-protecting agent;

[0027] Step 2: Line the inside of the screen basket with a layer of cotton cloth, and put about 1 / 4 of the volume of the screen basket on the bottom of the quartz sand;

[0028] Step 3: After taking out the peony flowers and peony flowers soaked in step 1, put them on the quartz sand in the sieve basket, then slowly add the quartz sand, and put the peony flowers and peony flowers between the petals of the peony flowers and peony flowers. The whole flower is completely filled with quartz sand;

[0029] Step 4: Place the sieve basket in a dry, ventilated, and shaded environment with a temperature of 20-22°C for 28-30 hours;

[0030] Step 5: Heat the screen basket to 26-30°C for 12-15 hours;

[0031] Step 6: Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com