Floor scrubber

A washing machine and brush motor technology, which is applied in the cleaning field, can solve the problems of scattered washing machine system and non-centralized management, and achieve the effects of reducing the occupied area, cleaning thoroughly, and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

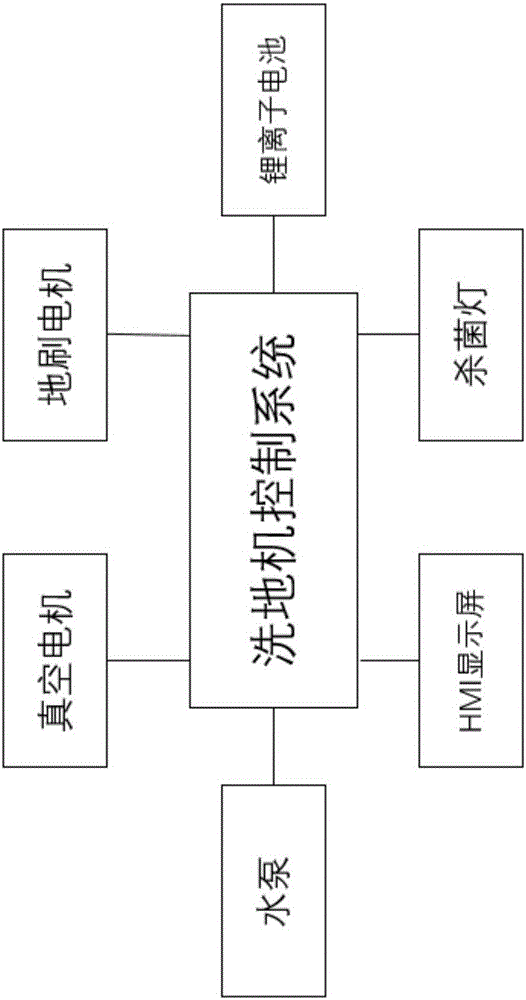

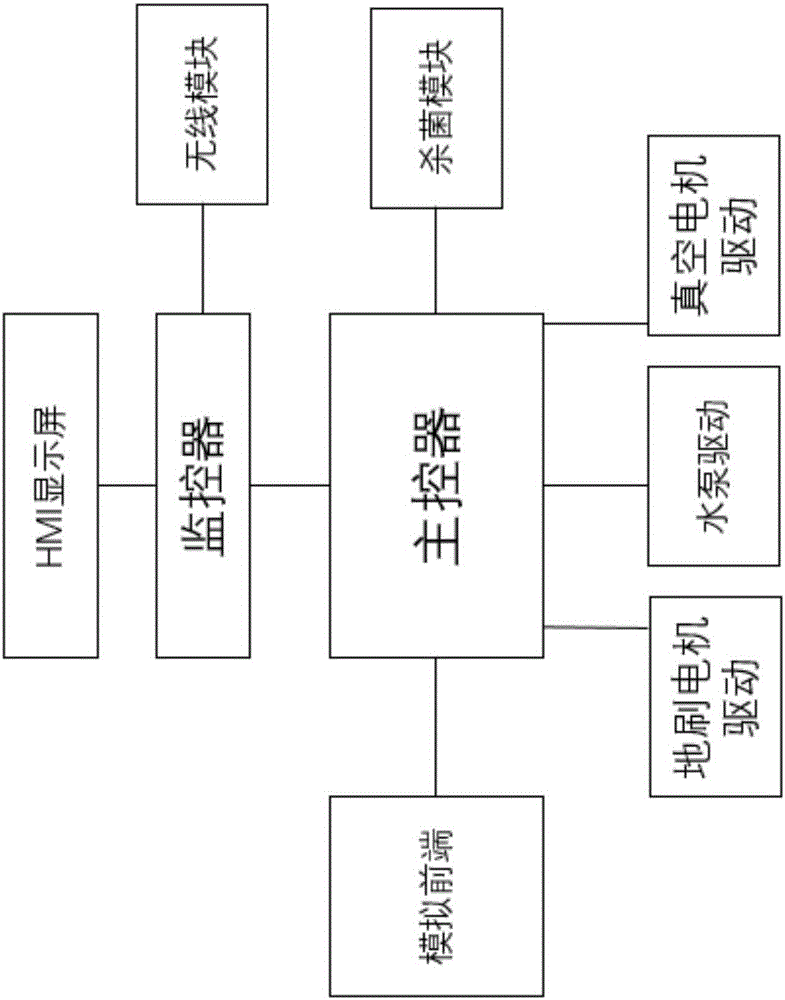

[0026] figure 1 A block diagram of the washing machine provided by the present invention is shown.

[0027] It can be seen from the figure that the scrubber provided by the specific embodiment of the present invention includes a scrubber control system, a floor brush motor, a water pump, a lithium-ion battery, and a vacuum motor, as well as a sterilization module and an HMI touch screen. The present invention changes the existing design that each module of the washing machine is independent of each other and needs to be managed separately, creatively unifies each module, uses the central control system for centralized management, greatly increases the degree of integration, and greatly simplifies The system structure of the washing machine.

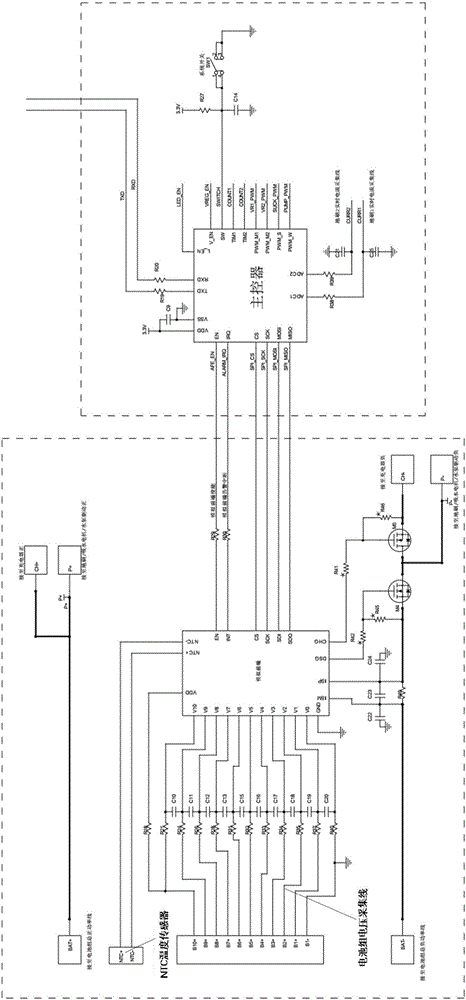

[0028] The floor washing machine provided by the specific embodiment of the present invention uses a lithium-ion battery, and the volume of the traditional battery is significantly reduced compared with that of the traditional battery. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com