Online UV (Ultraviolet) coating system of hotly-galvanized steel pipe and galvanized strip pipe

A coating system, hot-dip galvanizing technology, applied in the direction of coating, device for coating liquid on the surface, spray booth, etc. The effect of reducing the probability of occurrence, prolonging the life, and improving the corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

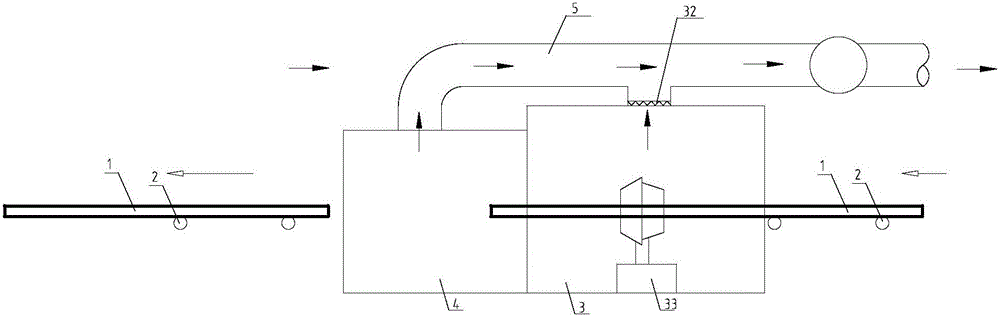

[0027] See Figure 1 to Figure 4 , the figure shows a hot-dip galvanized steel pipe provided by the embodiment of the present invention, a galvanized strip pipe online UV coating system, which includes a roller conveying device, a UV spraying room 3, a curing room 4 and an exhaust device 5; wherein ,

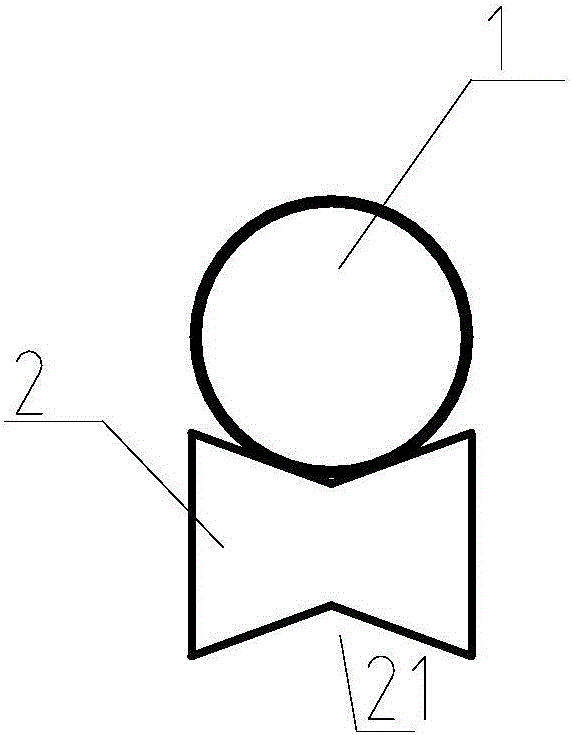

[0028] The roller conveying device is provided with several conveying rollers 2 arranged side by side for conveying hot-dip galvanized steel pipe or galvanized strip pipe 1;

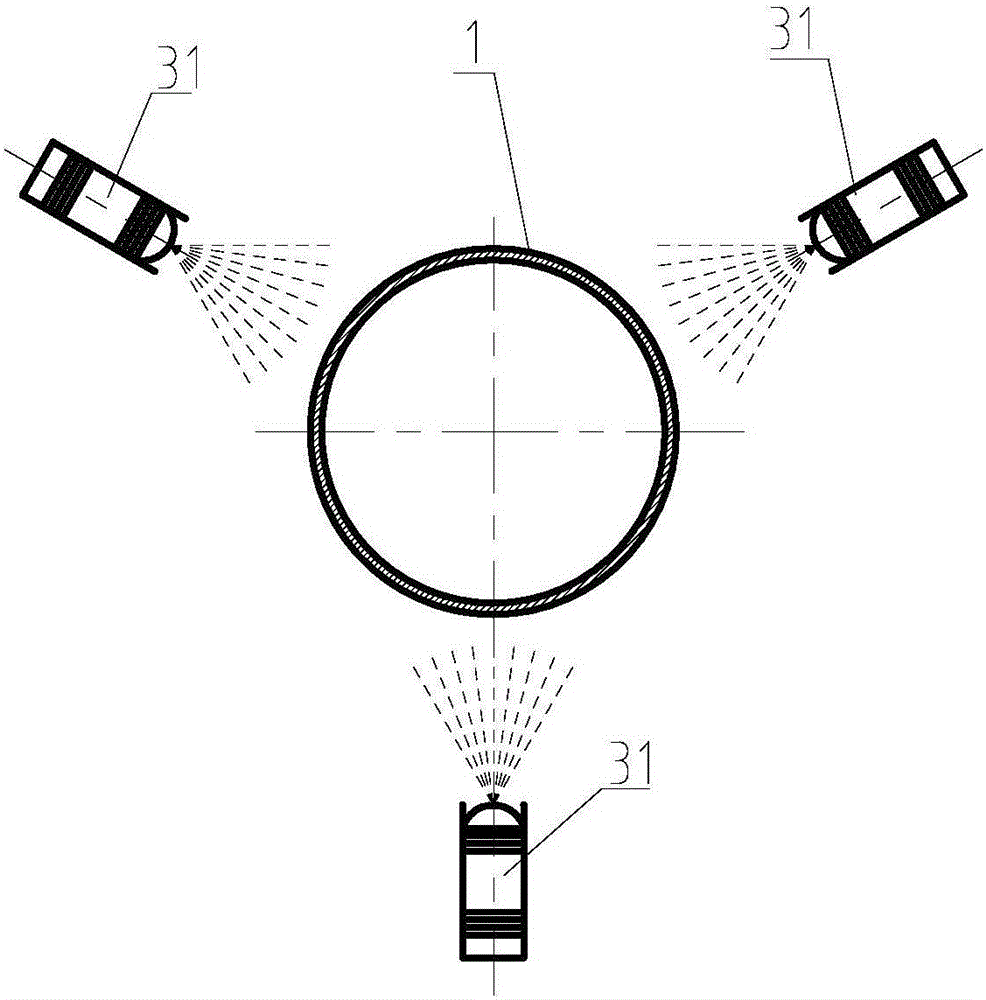

[0029] The interior of UV spraying room 3 is provided with spraying mechanism, and this spraying mechanism comprises the spray gun 31 that several cocircles are arranged; The top is provided with a first air vent;

[0030] The curing chamber 4 is arranged nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com