Rail-craning trolley-frame boring technology

A technology of small frame and rail crane, which is applied in the direction of boring/drilling, manufacturing tools, metal processing equipment, etc. It can solve the problems of low performance, low initial accuracy, high maintenance cost, etc., and achieve high processing accuracy and stability , Reduce production cost, reduce the effect of renovation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

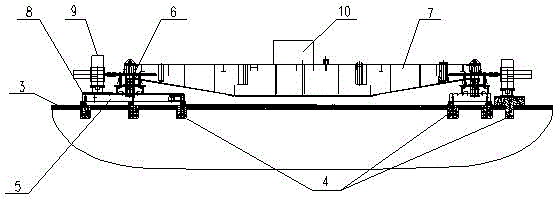

[0028] like Figure 1 to Figure 3 As shown in the figure, a boring process of a rail crane trolley frame, the trolley frame is bored with a CNC gantry fixed beam boring and milling machine, and the specific steps are as follows:

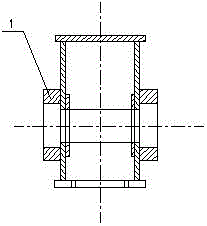

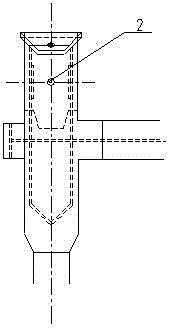

[0029] (1) For the trolley frame with the heavy plate inside the wheel box of the trolley frame, two heavy plates 1 are welded at the corresponding positions on the outside of the wheel box of the trolley frame. A through-hole 2 of Φ40mm is opened on the panel and the bottom plate with an iron-absorbing drill, and the through-hole 2 is set on the track opening line of the trolley frame and the upper and lower positions are consistent;

[0030] (2) Fix the foundation 4 on the cement floor 3, arrange the tire frame 5 on the fixed foundation 4, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com