Anti-deviating energy-saving type microwave vulcanization device achieving stable vulcanization and using method thereof

A microwave vulcanization, anti-deviation technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of difficult control of process parameters, temperature and humidity, affecting the normal transportation of brown fiber mattresses, and unstable vulcanization effect. , to achieve the effect of reducing ineffective working time, saving equipment investment costs, and saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

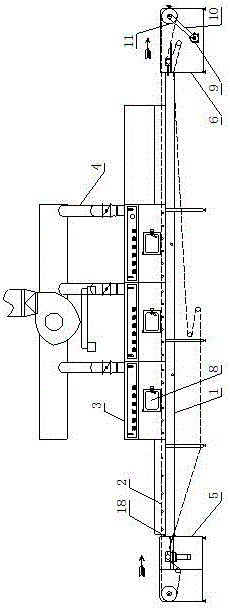

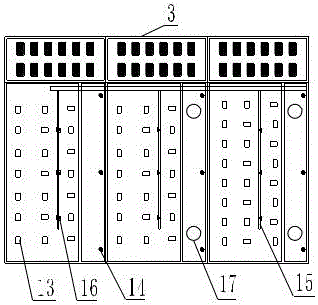

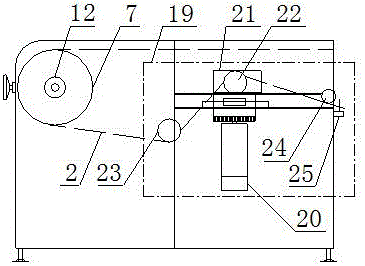

[0016] Example 1 . An anti-deviation and energy-saving microwave vulcanization device with stable vulcanization, the composition is as shown in the figure 1-3 shown , including stand 1 , bracket 1 conveyor belt 2 ,conveyor 2 There are more than one vulcanization tanks distributed continuously above 3 , vulcanization box 3 above the dehumidification port 17 Connected with dehumidifier 4 ,conveyor 2 The head end is equipped with a master control device 5 ,conveyor 2 power unit at the end 6 ; The master control device 5 including passive shaft 7 , passive shaft 7 There is a deviation correction device next to it 19 , passive shaft 7 Encoder 12 ; said power plant 6 including drive motor 9 ,motor 9 drive belt 10 with drive shaft 11 Connection; drive shaft as described 11 via conveyor belt 2 with passive shaft 7 connection; said conveyor belt 2 There is also a material sensor at the head end 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com