Method for judging component faults of reverse osmosis water purifier based on water pressure detection

A technology of fault judgment and reverse osmosis, applied in chemical instruments and methods, osmosis/dialysis water/sewage treatment, reverse osmosis, etc., can solve problems such as tap water pressure fluctuations, difficulties, and obstacles to the application of intelligent control methods, and achieve adaptability Strong, simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

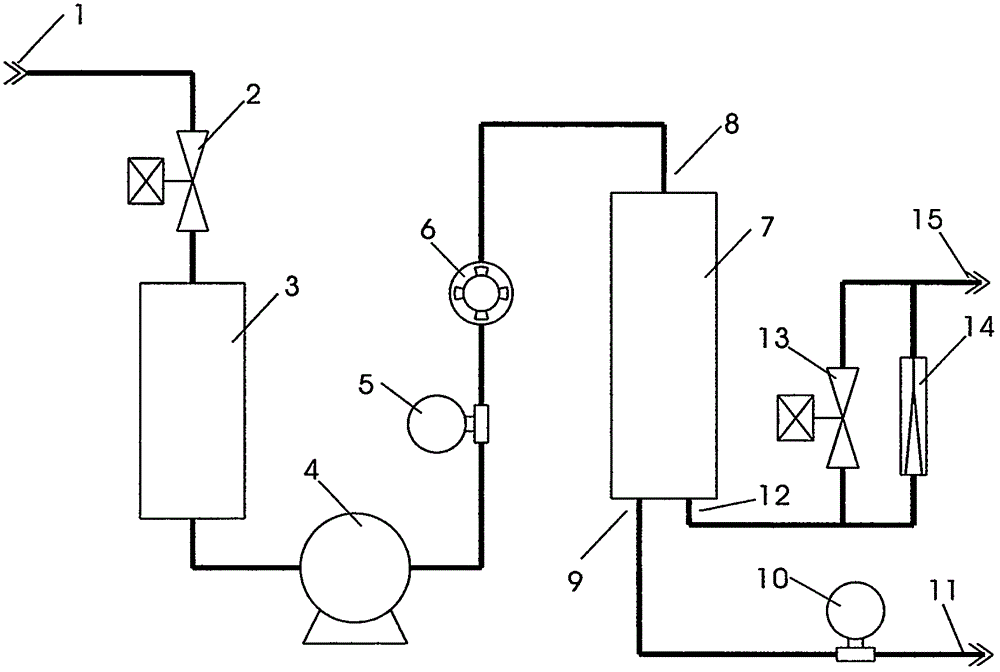

[0045] figure 1 Shown is the water flow chart of the reverse osmosis water purifier, the water flow path is: water inlet 1, water inlet solenoid valve 2, pre-filter element 3, water pump 4, water inlet digital pressure sensor 5, water inlet flow meter 6, enters the reverse osmosis The reverse osmosis membrane water inlet 8 of the membrane 7, the treated fresh water passes through the reverse osmosis membrane fresh water outlet 9, the water outlet digital pressure sensor 10, the fresh water outlet 11, the treated concentrated water passes through the reverse osmosis membrane concentrated water outlet 12, and rinses Electromagnetic valve 13, concentrated water flow limiting valve 14, concentrated water outlet 15.

[0046] It can be seen from the water process that the water pressure of the water source will affect the signal of the water inlet digital pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com