Novel drag reducer for fracturing

A drag reducer and fracturing technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of inability to completely inhibit shearing and molecular chain breakage, and achieve good environmental performance, bacterial erosion resistance, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

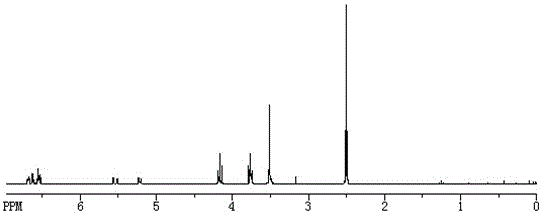

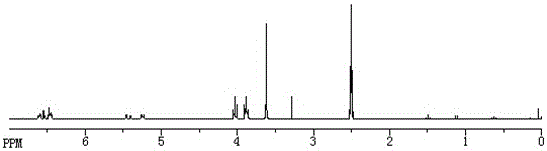

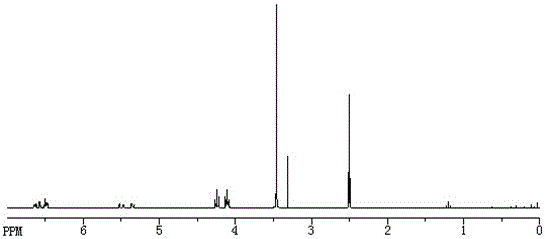

Image

Examples

Embodiment approach

[0042] As a preferred embodiment of the present invention, the vinylbenzocrown ether is selected from 4-vinylbenzo-18-crown-6, 4-vinylbenzo-21-crown-7, 4- One of vinyl benzo-24-crown ether-8. Preferably, the vinylbenzocrown ether is selected from 4-vinylbenzo-21-crown-7 or 4-vinylbenzo-24-crown-8. More preferably, the vinylbenzocrown ether is 4-vinylbenzo-24-crown-8.

[0043]As a preferred embodiment of the present invention, the vinyl benzo crown ether is prepared from raw materials containing 4-vinyl-1,2-benzenediol and chloroglycol compounds.

[0044] The preparation method of described vinyl benzo crown ether is as follows:

[0045] (1) Put the weighed glycol compound into a 250 mL double-necked flask equipped with a reflux condenser, and add excess thionyl chloride and 2-3 drops of DMF. Heat to reflux for 12-18 h, cool to room temperature after the reaction is complete, and use a rotary evaporator to dry the thionyl chloride to obtain chloroglycol compounds.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com