Making method of constant-force self-locking nuts and constant-force self-locking nuts

A technology of self-locking nut and manufacturing method, applied in the direction of nuts, screws, bolts, etc., can solve the problem of material waste, and achieve the effects of reducing product weight, high safety and reliability, and controlling material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

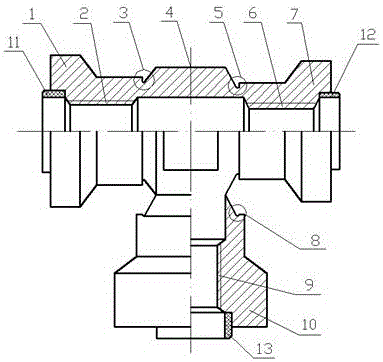

Image

Examples

Embodiment

[0020] The manufacturing method of this example is that the shape of the blank is formed by direct hot forging and pressing of the bar, and then formed by machining. The theoretical basis is the use of advanced high-tech materials. The strength and plasticity of the material are excellent. The tensile strength and fatigue strength are greatly enhanced after forging and pressing forming produces cold work hardening, and shape memory alloys can also be used to form and rapidly cool at high temperatures to obtain blanks of any shape. The materials used are superalloys (such as: GH2132 、 GH4169 、 GH30 、 GH738 、 GH4698 、 GH2696 ), titanium alloys (such as: TC4 、 TC16 ), alloy structural steel (such as: 30CrMnSiA 、 40CrNiMoA) , carbon structural steel (such as: ML35 、 ML25 ), aluminum alloy (such as: 2A11 、 2A12 ). Copper alloys (eg: H62 ) and other materials with good plasticity are acceptable. The invention changes the single proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com