Energy-efficient fire coal multipurpose hot-blast stove

A hot blast stove, energy-saving technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of unreasonable structural settings and low thermal efficiency of coal-fired hot blast stoves, and achieve excellent inventiveness and thermal efficiency. High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

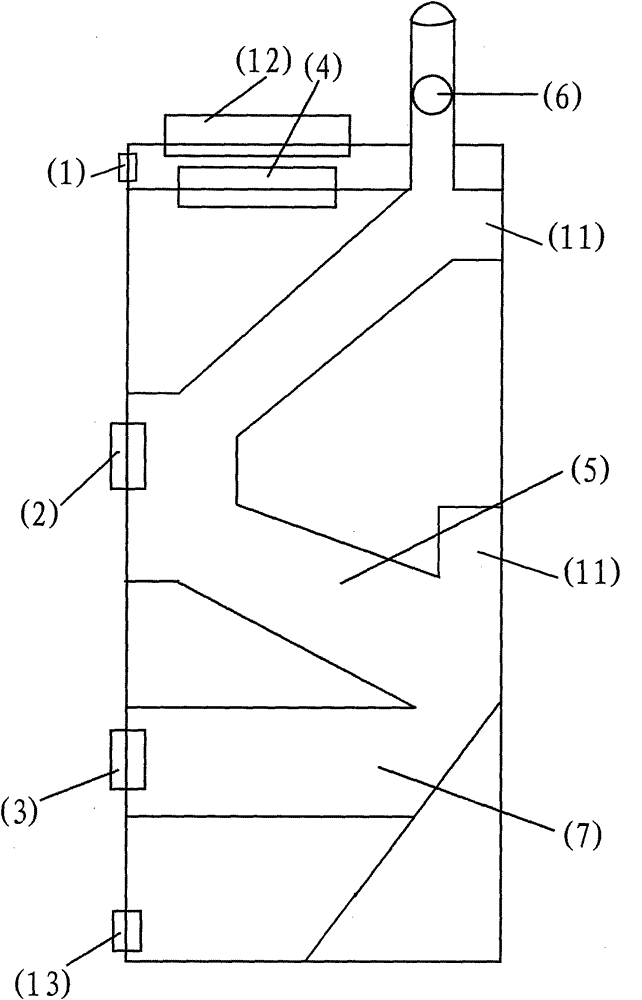

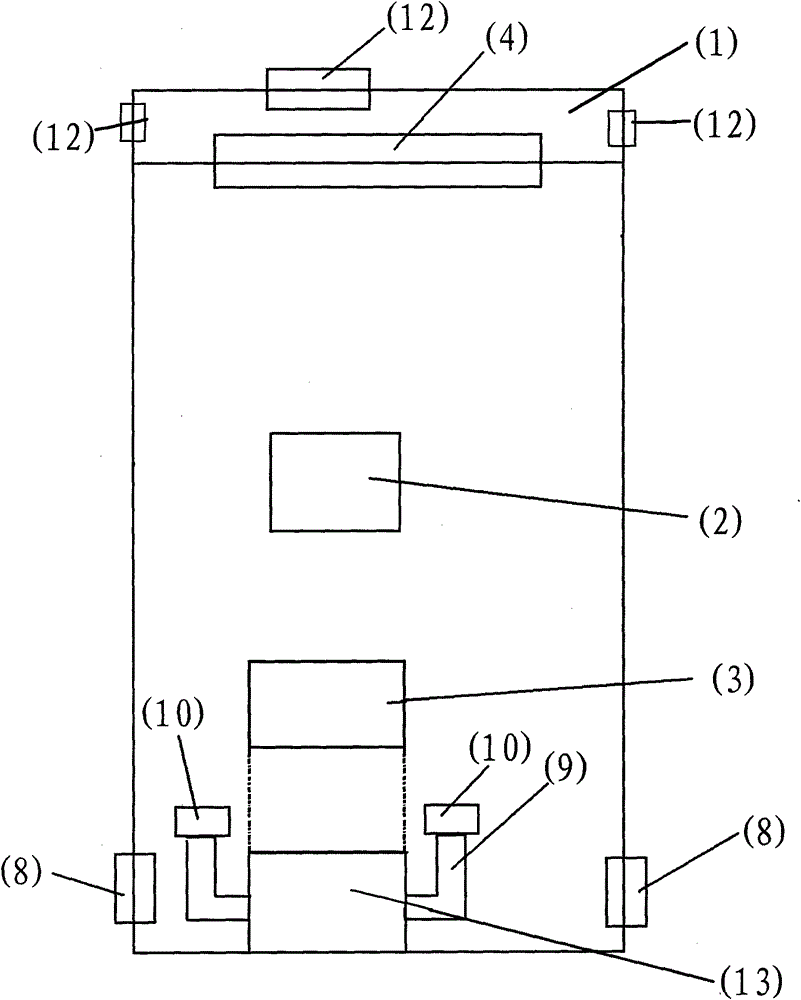

[0014] This energy-saving coal-fired multi-purpose hot blast stove has a combustion chamber 7, connecting hot blast tube and smoke tube, including hot blast tube cover box 11, a number of hot blast tube 5, a fan 4 on the top, as the combustion chamber, 7, start When the temperature exceeds the material temperature, open the fan 4, open the air inlet 9, and use the fan 4 to heat the hot air tube. The hot air is pressed down, and the hot air is output from the hot air outlet. When the temperature exceeds the temperature of the material, open the humidity control door 1, close the flue adjustment cover 6, and Hot air outlet 8.

[0015] Description summary

[0016] An energy-saving coal-fired multi-purpose hot blast stove, which is provided with a hot blast stove body. It is characterized in that it is also provided with a hot blast sleeve 5 and a hot blast tube cover box. The fan 4, the temperature control door 1, the steam valve and the external connection vent 12, the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com