Forced circulation hot water system with self-power-outage-protection function

A technology of forced circulation, hot water system, applied in the directions of preheating, water heater, feed water heater, etc., can solve the problems of power failure protection, drum fatigue, clapboard problems, etc., to improve safety, high safety, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

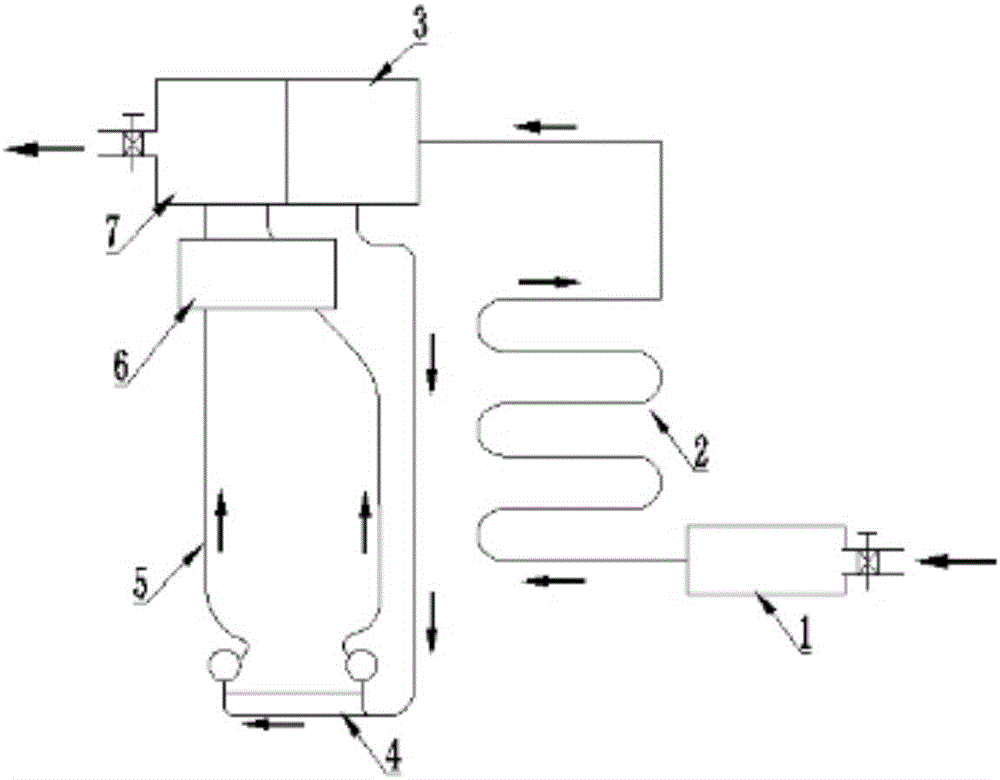

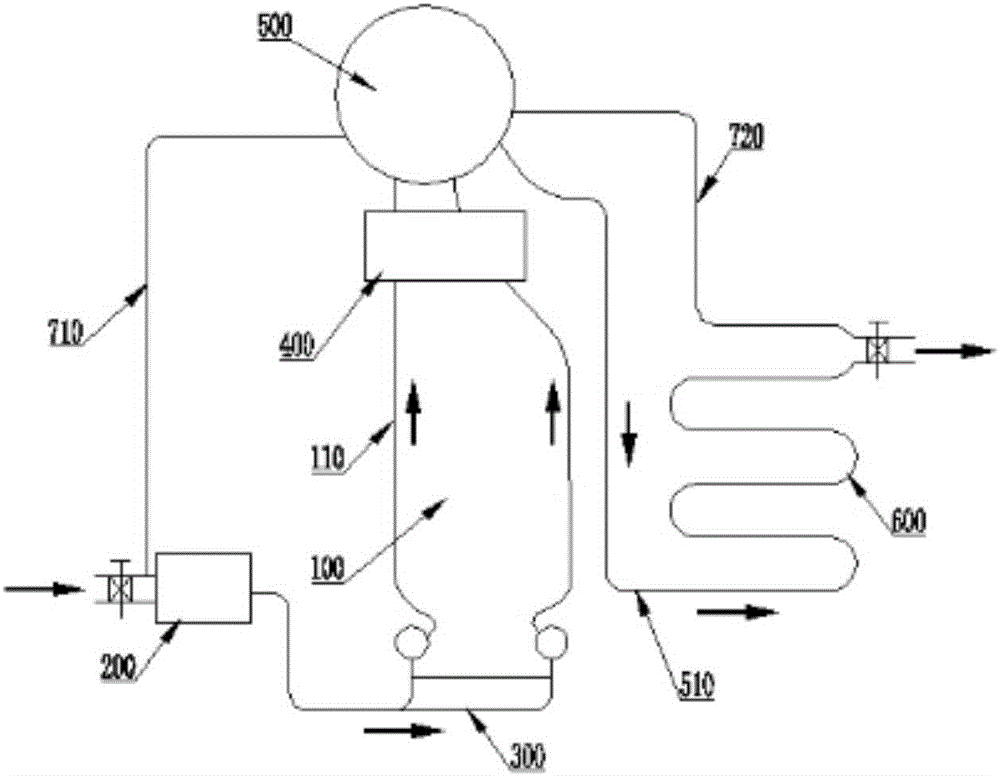

[0045] figure 2 The schematic diagram of the forced circulation hot water system with self-power-off protection function provided by Embodiment 1 of the present invention, as shown in figure 2 As shown, the forced circulation hot water system provided in this embodiment includes: water-cooled hearth 100, water-cooled wall 110, return water header 200, water-cooled lower header 300, water-cooled upper header 400, drum 500, coal-saving Device 600 and recirculation pipe;

[0046] Specifically, the inlet of the return water header 200 of the hot water boiler in this embodiment is connected to an external water pipe, so that the external water pipe can send water to the return water header 200 . At the same time, the outlet end of the return water header 200 is connected to the water inlet end of the lower header 300 of the water cooling wall, and the return water header 200 is used to supply water to the lower header 300 of the water cooling wall.

[0047] The water-cooled low...

Embodiment 2

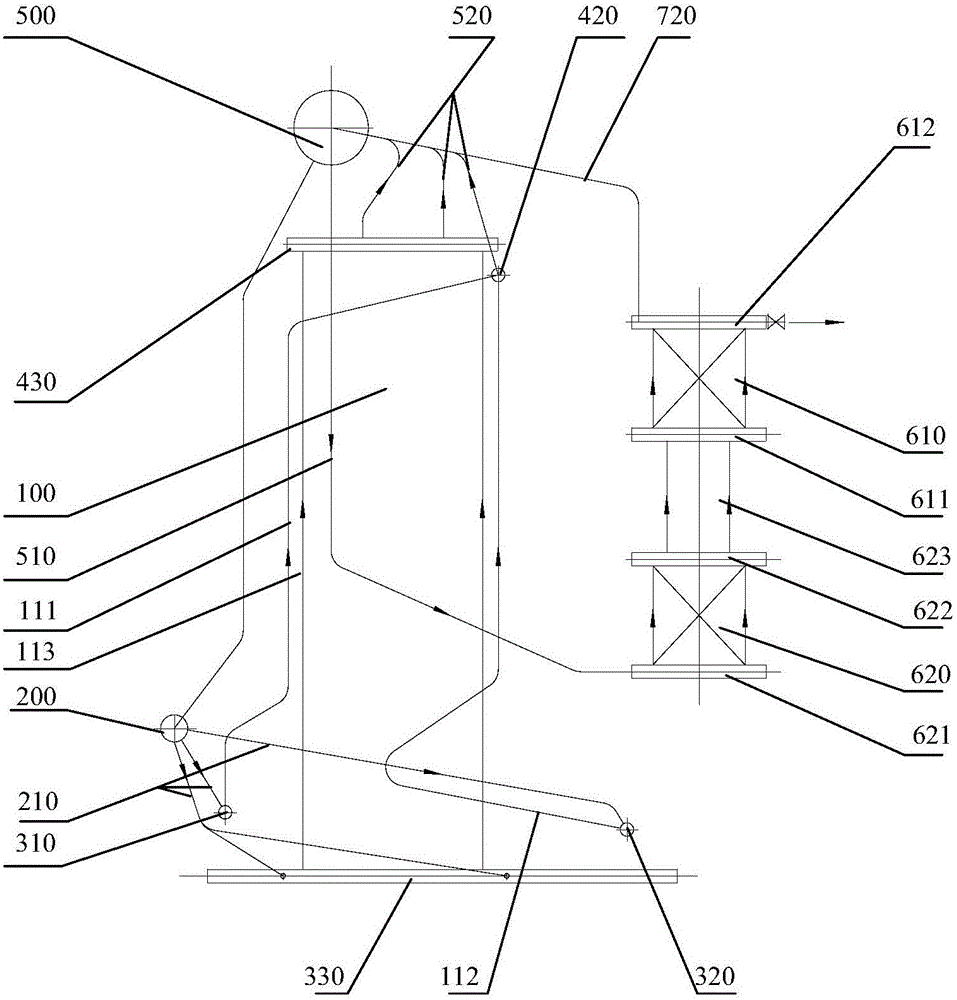

[0066] Figure 3a It is a schematic structural diagram of a forced circulation hot water system with self-power-off protection function provided by Embodiment 2 of the present invention. Figure 3b Another structural schematic diagram of the forced circulation hot water system with self-power-off protection function provided by Embodiment 2 of the present invention. Such as Figure 3a , Figure 3b As shown, on the basis of the first embodiment above, further, the water-cooled lower header 300 of the forced circulation hot water system with self-power-off protection function provided by this embodiment includes: the front wall water-cooled lower header 310, the rear The wall water-cooled lower header 320 and the side wall water-cooled lower header 330 , wherein there are at least two side wall water-cooled lower headers 330 .

[0067] Specifically, the water outlet of the return water header 200 is respectively connected to the lower header 310 of the front wall water coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com