Methane conversion oven device of gas chromatograph

A technology of gas chromatography and methane detection, which is applied in the field of structural design of gas chromatograph methane reformer, can solve the problems of complex structure of methane reformer device, inconvenient installation and maintenance, and unreasonableness, so as to improve conversion efficiency and accuracy The effect of high reliability, simple process and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

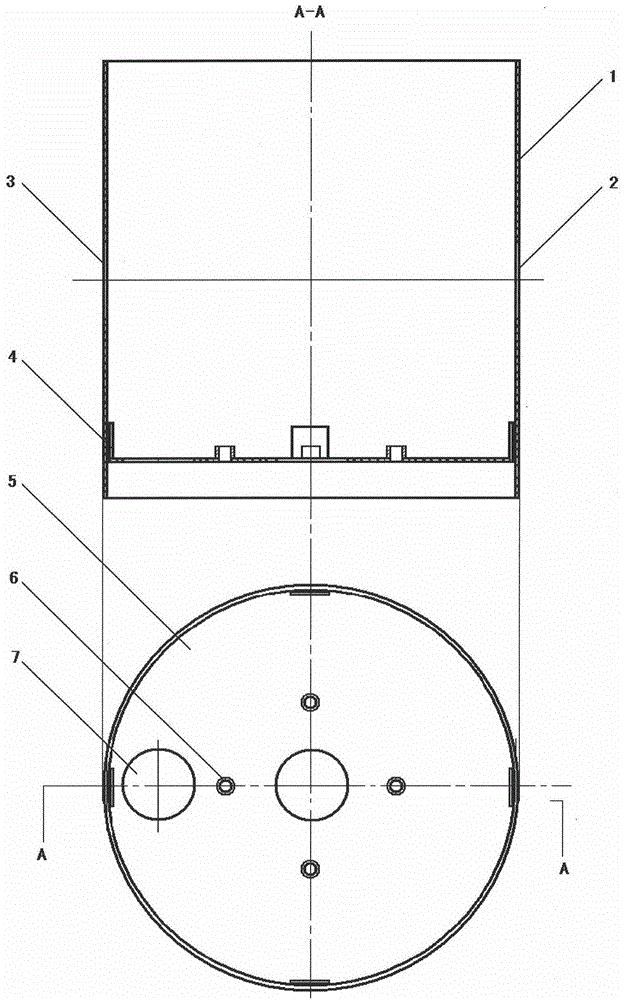

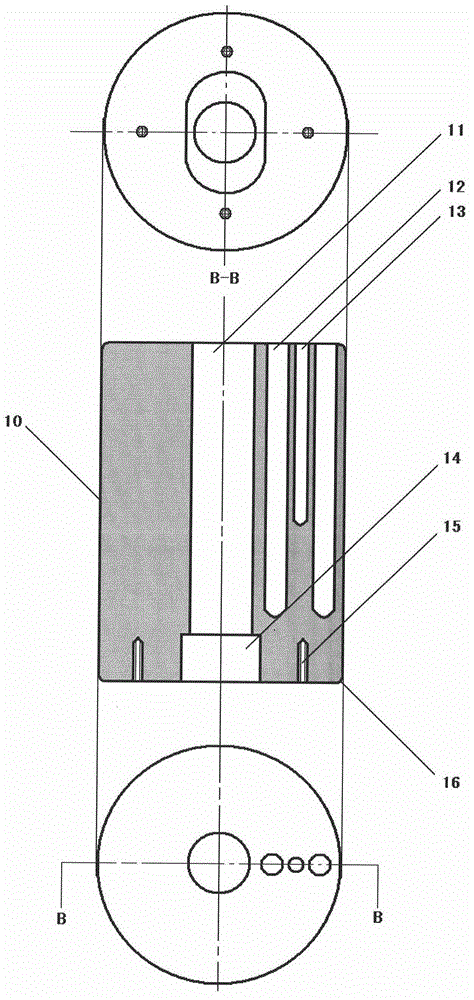

[0013] The specific embodiment of the insulation cylinder of the present invention is shown in the attached figure 1 , use a stainless steel tube with a wall thickness of 1mm to make the insulation tube (1), drill a right outlet hole (2) on the right side of the middle, and drill a left outlet hole (3) on the left side; use a stainless steel tube with folded feet (4) at the four corners The circular plate is used as the fixed plate (5), and four supporting columns (6) with holes are riveted on the same circumference above, perpendicular to each other, and two assembly holes (7) are drilled, and welded on the stainless steel at the folding feet (4). The lower interior of the tube. The stainless steel cylinder with a wall thickness of 1mm is a neat decorative material with a very low price. It can be cut directly, saving labor and time, and not wasting materials.

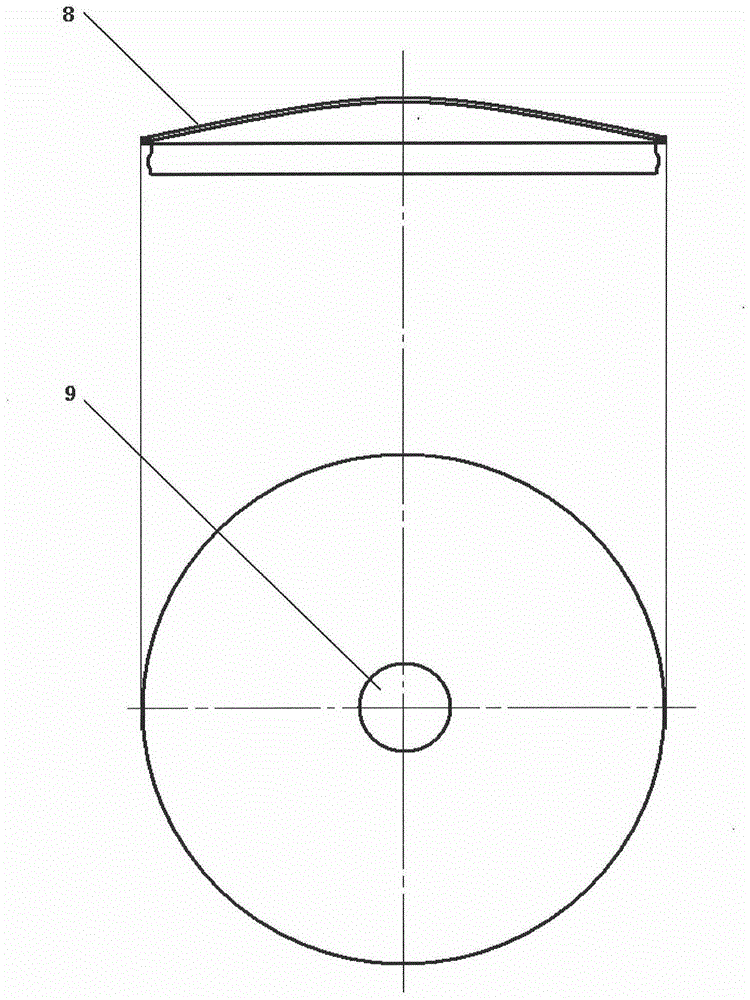

[0014] For the specific implementation of the insulation cylinder cover of the present invention, see the attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com