Electromagnetic transmitter with annular connectors

A technology of a connector and a transmitter, applied in the field of national defense weapons and electromagnetic launch, can solve the problems of speed generation, contact and friction can not be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

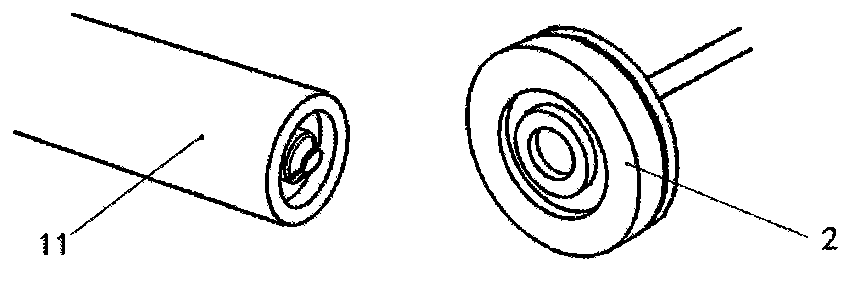

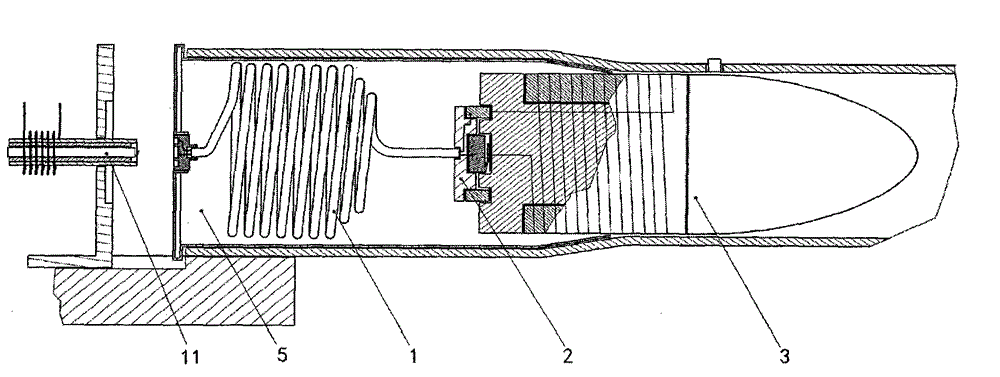

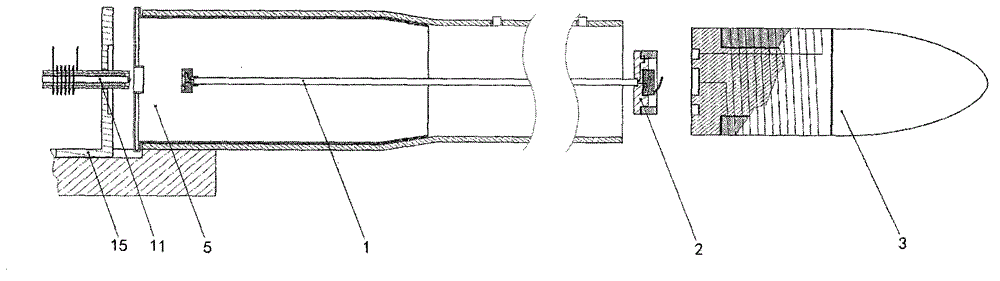

[0040] Attached below figure 1 Describe the specific implementation method: an electromagnetic transmitter with a ring connector, which is composed of a flexible cable 1, a ring connector 2, an emitted part and an emitting part, and is characterized in that the flexible cable 1 It consists of two wires insulated from each other, has a certain degree of flexibility, can be coiled and placed inside the cartridge case 5, and a ring connector 2 can be fixed at both ends, and the two ends of one of the wires can be connected to two wires respectively. The outer ring electrode on the ring connector 2, and the two ends of the other wire can be respectively connected to the middle circular electrodes on the two ring connectors 2, the length of the flexible cable 1 should meet the requirement that the position of the starting end remains unchanged In the case of the warhead 3, its end can reach the position of the mouth of the launch tube 6 or the position of the photoelectric controll...

example 1

[0060] Example 1 illustrates the situation that the fired part is composed of a projectile 3, a projectile coil 4 and a cartridge case 5, and is combined with a flexible cable 1 and two ring connectors 2 fixed at both ends: for the convenience of description, the The warhead coil 4 and all the launch tube coils 8 have the same winding direction. When there are two annular connectors 2, the one that is plugged with the bullet 3 is called the first annular connector, and the one that is stuck in the opening at the bottom of the cartridge case 5 is the second. Two ring connectors, and numbered 100, 101, 102 for a plurality of photoelectric controllers 7 respectively in sequence, the corresponding electromagnetic relay 9 is numbered 200, 201, 202, and the corresponding transmitting tube coil 8 is numbered 300 , 301, 302, as attached Figure 9 As shown, in order to facilitate the distinction, the circuit diagram is attached Figure 10 And attached Figure 11The weak current contr...

example 2

[0061] Example 2, illustrating the situation that the launched part is combined with the flexible cable 1 and a ring connector 2 fixed at one end: this example is basically the same as Example 1, except that the first ring at the bottom of the bullet 3 in Example 1 is When the connector is removed, the electric current passes through the wires directly to the warhead coil 4 during work, and the whole process is basically unchanged, except that when the final warhead 3 flies out of the mouth of the launch tube 6, the soft cable 1 and a ring fixed at one end The connector 2 and the warhead 3 cannot be separated, and several parts fly to the target together. The advantage of this example is that there is one less part, and the process is simpler and more reliable. The disadvantage is that the soft cable 1 will increase the air resistance and affect the speed. This example There are other disadvantages and it is not the preferred solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com