Bridge deck pavement layer field shear test device and method

A technology of shear test and pavement, which is applied in the direction of measuring devices, using stable shear force to test the strength of materials, instruments, etc., can solve the problem of inability to accurately measure the damage of bridge deck pavement Bridge deck pavement shear characteristics and other issues, to achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

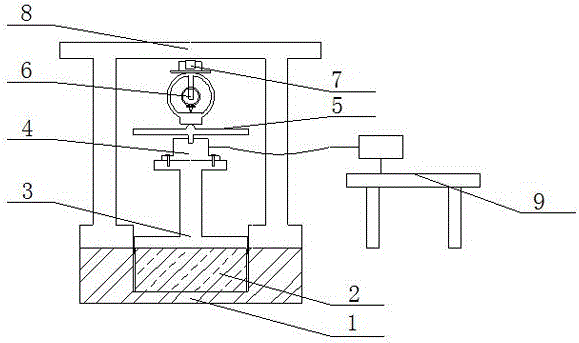

[0066] A method for bridge deck field shear test, comprising the following steps:

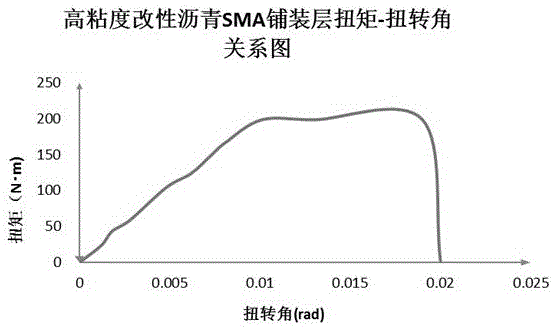

[0067] 1. Drilling, using a road drilling corer to drill a cylindrical specimen with a diameter of 10cm and a thickness of 7cm on the high-viscosity modified asphalt SMA pavement layer;

[0068] 2. Installation of shearing device:

[0069] 1) Install the specimen clamp to ensure that the specimen clamp is closely attached to the drilled cylindrical pavement specimen;

[0070] 2) Install the torque sensor, and install the torsion platform on the torque sensor;

[0071] 3) Place the recess in the middle of the bottom surface of the lower end of the force measuring ring on the spherical protrusion coated with butter in the middle of the torsion platform, place a hydraulic jack on the upper end of the force measuring ring, and erect a reaction force frame above the jack;

[0072] 3. Shear test: start the hydraulic jack, observe the tire pressure of 0.7MPa corresponding to the standard axle load t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com