Eddy probe array for detecting pipeline deformation

A probe array, eddy current probe technology, applied in the direction of electric/magnetic solid deformation measurement, measurement device, material magnetic variable, etc. The effect of wide frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

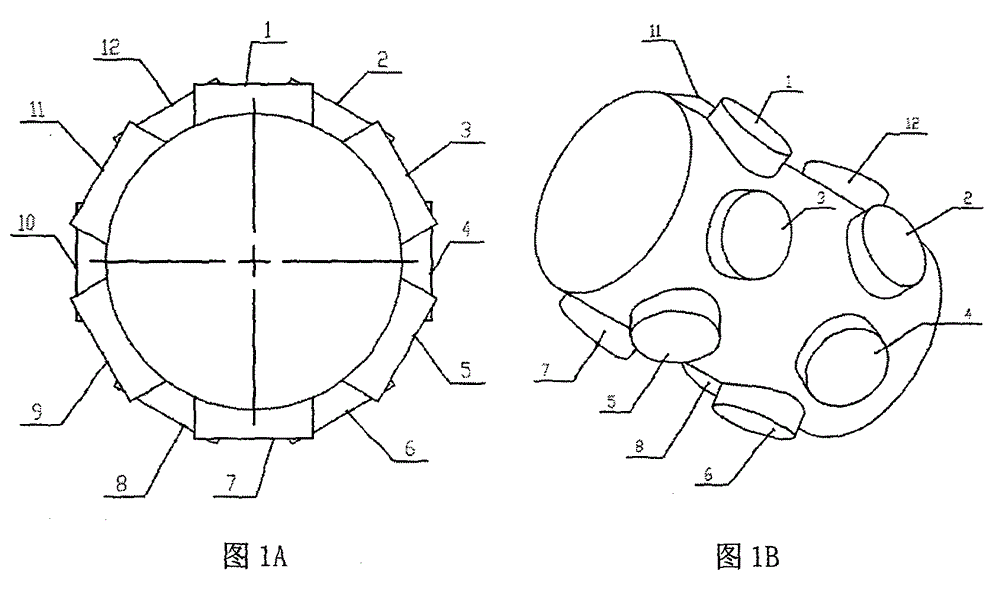

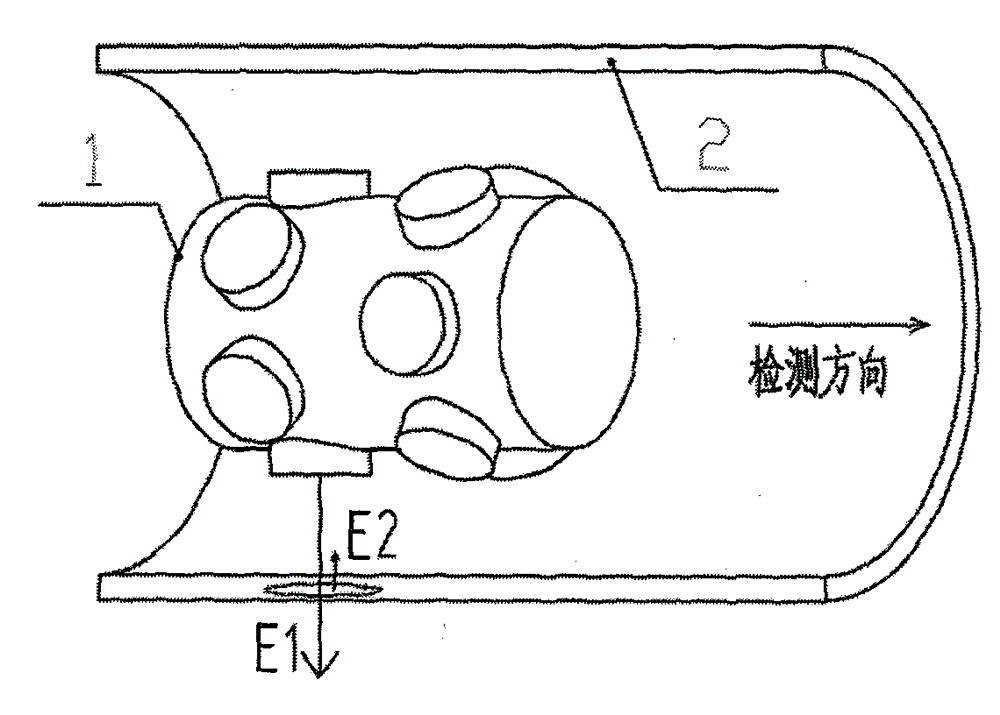

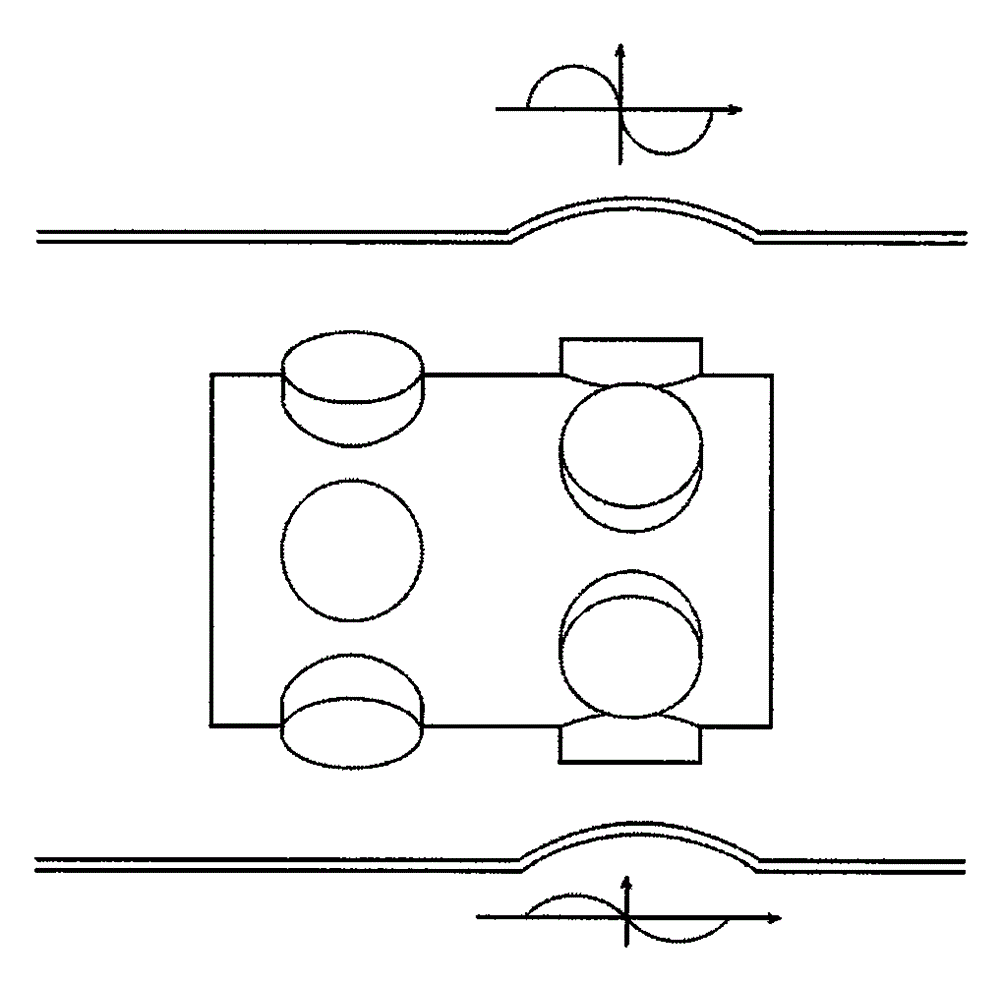

[0014] The present invention adopts the following methods to design and use the eddy current ranging probe:

[0015] In the process of non-destructive testing of pipelines, deformation detection technology is used to detect the geometric characteristics of pipelines. In the past, the swing arm probe of the deformation detector was a contact probe, and its number of channels determined its detection quality. The eddy current range-finding deformation detection probe of the present invention is a non-contact probe, which does not cause any damage to the inner surface of the pipeline, the coils of the eddy current sensor are arranged in a compact circumferential direction, the magnetic circuit covers a wide range, and the probability of missed detection is very low.

[0016] In the eddy current ranging sensor, the most important element is the coil, and its shape and size are related to the sensitivity and measuring range of the eddy current ranging probe sensor. Firstly, the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com