Liquid resistor load device for controlling resistance of liquid resistor through controller

A technology of load device and resistance liquid, which is applied in the direction of measuring device, motor generator test, and parts of electrical measuring instruments, etc. It can solve the problems of complex motion mechanism, high investment cost, and inability to meet the requirements of electrical performance testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

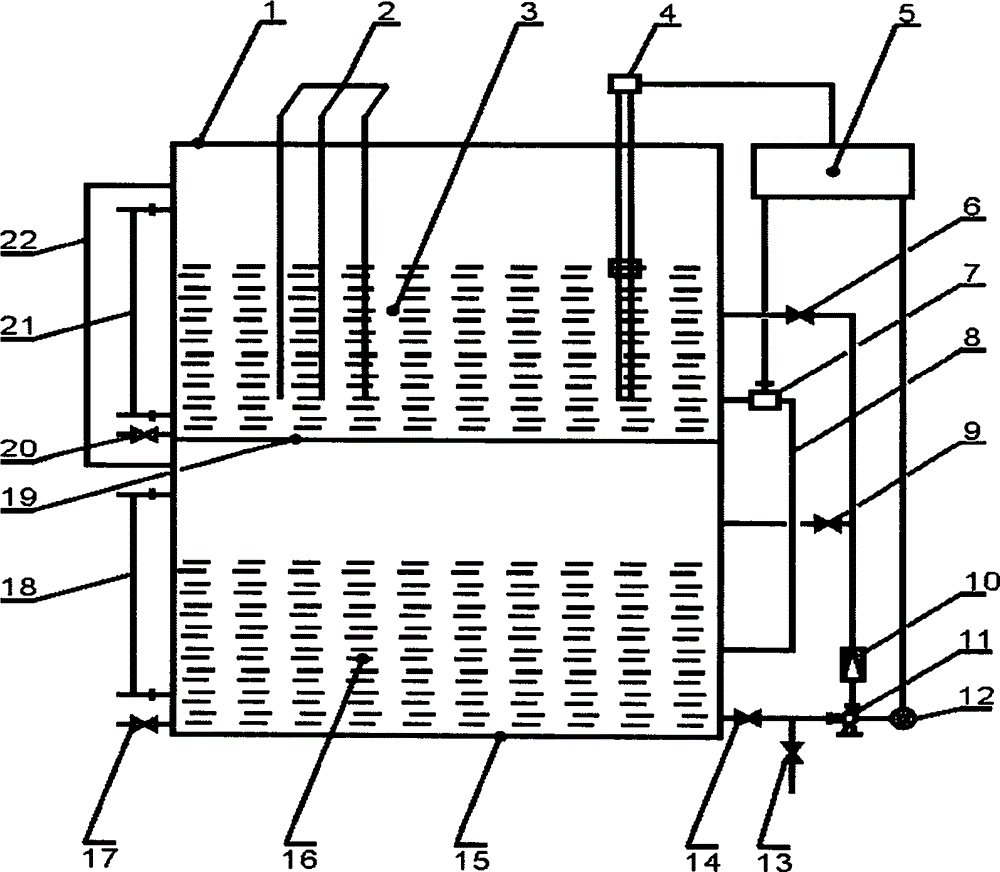

[0018] As shown in Figure 1, the liquid level sensor (4) transmits the electrical signal converted from the liquid level height of the resistance liquid (3) in the liquid resistance box (1) to the controller (5), and the controller (5) communicates with the electrical signal After the "setting value" is compared, it is judged whether the liquid level height of the resistance liquid (3) is appropriate.

[0019] When the liquid level of the resistance liquid (3) is higher than the "set value", the controller (5) sends an "open" signal to the solenoid valve (7) on the liquid phase connecting pipe (8) and sends a signal to the motor (12). "Stop" signal, the solenoid valve (7) on the liquid phase connecting pipe (8) "opens", the water pump (11) stops running, and the resistance liquid (3) in the liquid resistance box (1) flows to the Flow in the liquid storage tank (15), when the liquid level of the resistance liquid (3) is lowered to the "set value", the controller (5) compares th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com