Device and method for changing movement track of grinding medium of grinding machine based on magnetic field

A technology of motion trajectory and magnetic field direction, which is applied to educational appliances, instruments, grain processing, etc., can solve the problems of many tests, complex processing of irregular cross-section liners, and high test costs, etc., and achieves strong adaptability, simple and reliable structure , easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

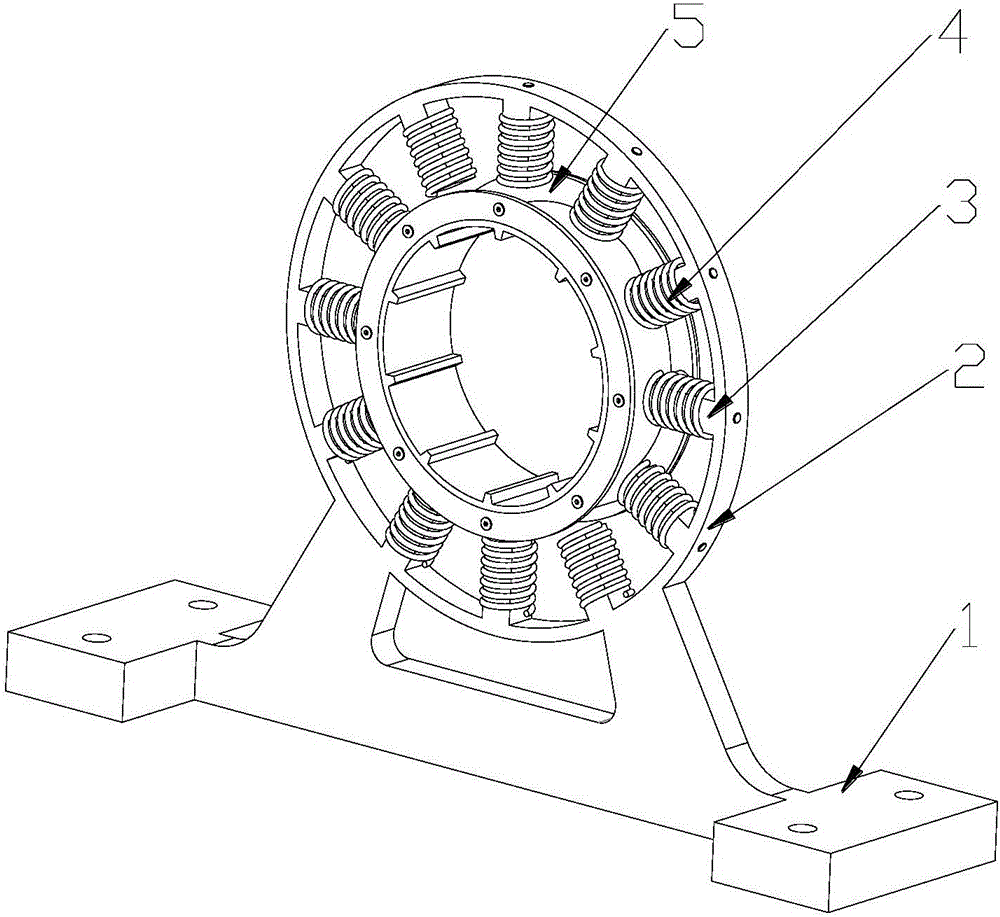

[0019] The ball mill impact and collision simulation test bench of the present invention includes a base 1, a coil housing 2, a magnet column 3, a coil 4, and a mill cylinder 5. The mill cylinder 5 is installed inside the coil housing 2 and has the same central axis position. And can rotate along its central axis, the coil housing 2 is installed and fixed on the base 1, the magnet column 3 is evenly fixed in the coil housing 2 by bolts, the central angle between two adjacent magnet columns 3 is 30 degrees, and the base 1 It is fixed on the ground by anchor bolts, and the coil 4 is wound on the magnet post 3 .

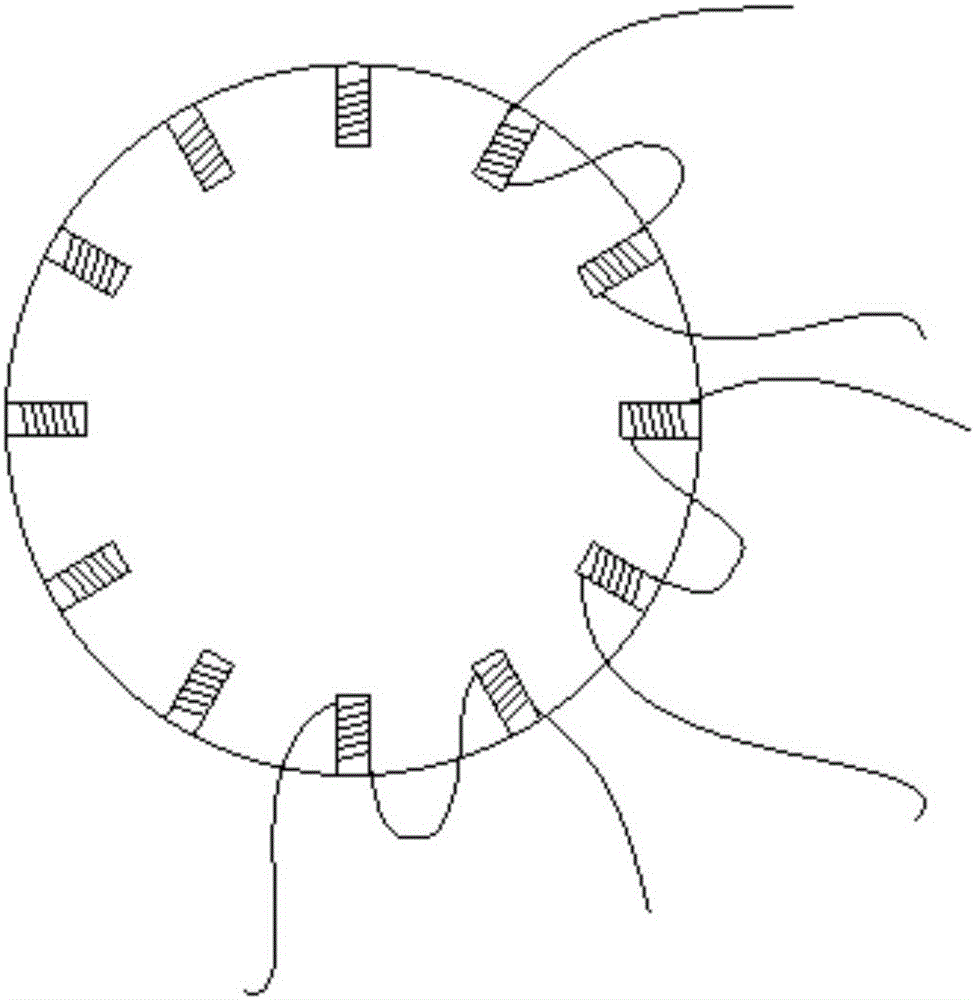

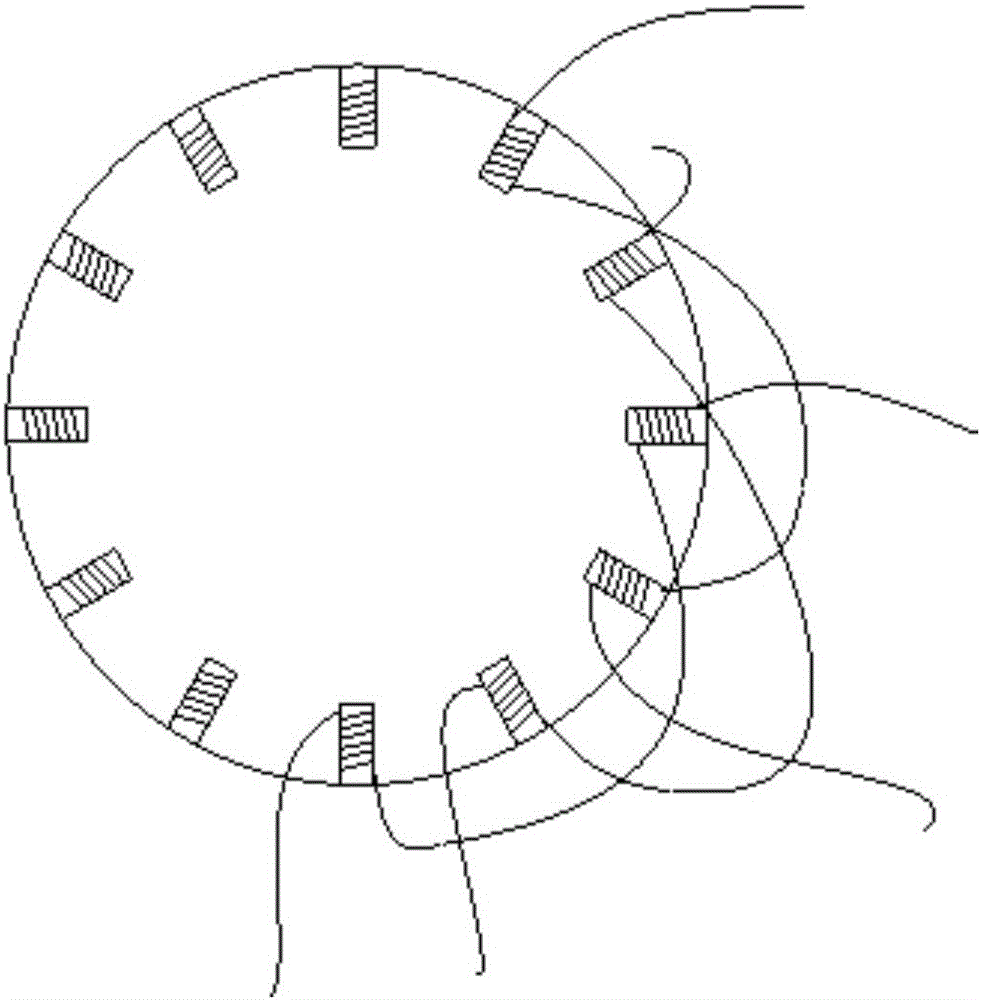

[0020] Since the magnet columns 3 are arranged inside the coil shell cylinder according to a certain angle, the commonly used motor rotor coil connection method will be separated by 30 degrees ( figure 2 ), 60 degrees ( image 3 ), 90 degrees or 120 degrees of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com