Anti-creeping aluminum alloy power cable with high performance

A power cable and aluminum alloy technology, which is applied in the direction of power cables with shielding layers/conductive layers, insulated cables, cables, etc., can solve the problem of loose structure, unsuitable for long-distance laying and overhead laying, tensile strength and elongation of pure aluminum core Low rate and other problems, to achieve the effect of increasing elongation, reducing installation cost, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, illustrate the concrete content of the present invention in detail:

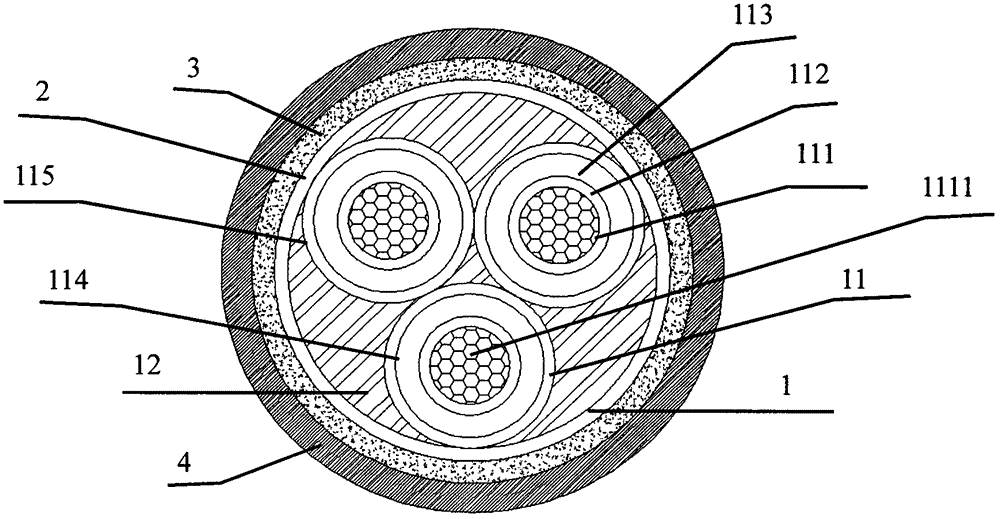

[0022] 1. If figure 1 The power cable shown is a stranded cable core unit 1, which includes a shielded conductor unit 11 and a non-hygroscopic flame-retardant filler 12, and the cable core unit 1 is extruded with an outer sheath 4. Between the unit 1 and the outer sheath 4, a non-hygroscopic flame-retardant tape 2 and an interlocking armor layer 3 are sequentially covered from the inside to the outside, and it is characterized in that: the shielded conductor unit 11 contains aluminum Alloy stranded conductor 111, shielding layer 112 extruded on aluminum alloy stranded conductor 111, silane cross-linked insulating layer 113 extruded on shielding layer 112, semi-conductive shielding layer 114 extruded on insulating layer 113, Copper tape shielding layer 115 wrapped on the semi-conductive shielding layer 114; the aluminum alloy stranded conductor 111 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com