A plant salt and a method of extracting the plant salt from suaeda salsa by adopting an ultrasonic-assisted enzymolysis process

The technology of Suaeda salsa and auxiliary enzymolysis is applied in the field of plant salt extraction, which can solve the problems of weak bacteriostatic effect and no bacteriostatic effect, and achieve the effect of smooth taste and strong taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 A method of extracting plant salt from Suaeda salsa using ultrasonic-assisted enzymolysis process

[0036] Include the following steps:

[0037] (1) cleaning

[0038] Select the tender stems and leaves of Suaeda salsa and the edible parts of cobs, cut them into sections with a length of 5 cm, and make a group of 10 sections;

[0039] Adjust the amount of cleaning water, keep the flow rate to a linear shape, keep the water flow rate at 11-15ml / s, control the water temperature at 0-10°C, and prepare brushes made of hair;

[0040] Put the cut section of Suaeda salsa stems and leaves on the index finger, moisten the brush, and gently brush along the veins of the stems and leaves until it is clean, and put the cleaned stems and leaves on the sieve tray to drain the water , the cleaning time of each group is 5-7 minutes;

[0041] Put the sectioned Suaeda salsa cobs in the palm of your hand, brush gently, and rotate while brushing. After cleaning, put them on a...

Embodiment 2

[0065] Example 2 Combined factor analysis experiment

[0066] The method described in Example 1 was used to extract plant salt, and the experiment was carried out by changing only the factors of pH, temperature and time of enzymatic hydrolysis in the second stage of enzymatic hydrolysis in step (6).

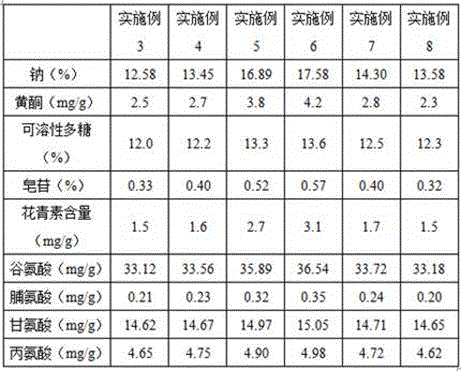

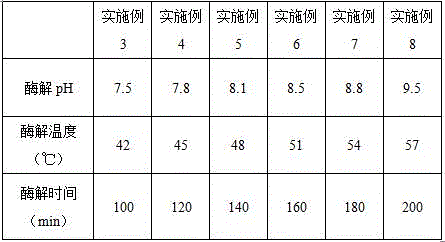

[0067] Table 1 Analysis experiment of combined factors of pH, temperature and time of enzymolysis

[0068]

[0069] Table 2 Indexes of extracted plant salts

[0070]

[0071] Through the above factor combination experiment, it can be seen that Example 5 and Example 6 are preferred examples, that is, in the second-stage enzymatic hydrolysis process in step (6), the enzymatic hydrolysis pH is preferably 8.1-8.5, and the enzymatic hydrolysis temperature is preferably 48- 51℃; the enzymolysis time is preferably 140-160min.

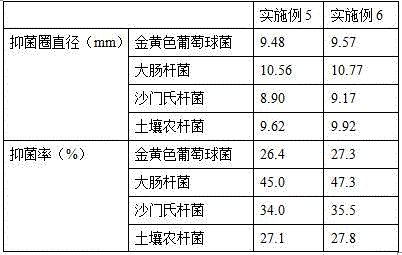

[0072] The preferred embodiment 5 and embodiment 6 are mixed with the solution of 20mg / ml, carry out antibacterial test, the result is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com