Program-controlled flushing device for vacuum belt dewatering filter cloth

A technology of vacuum belt conveyor and washing device, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., which can solve the problems of increasing human supervision burden, high labor cost, easily damaged circuit equipment and roller bearings, etc., and achieves reduction Risk of flushing, even and effective flushing, avoiding the effect of splashing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

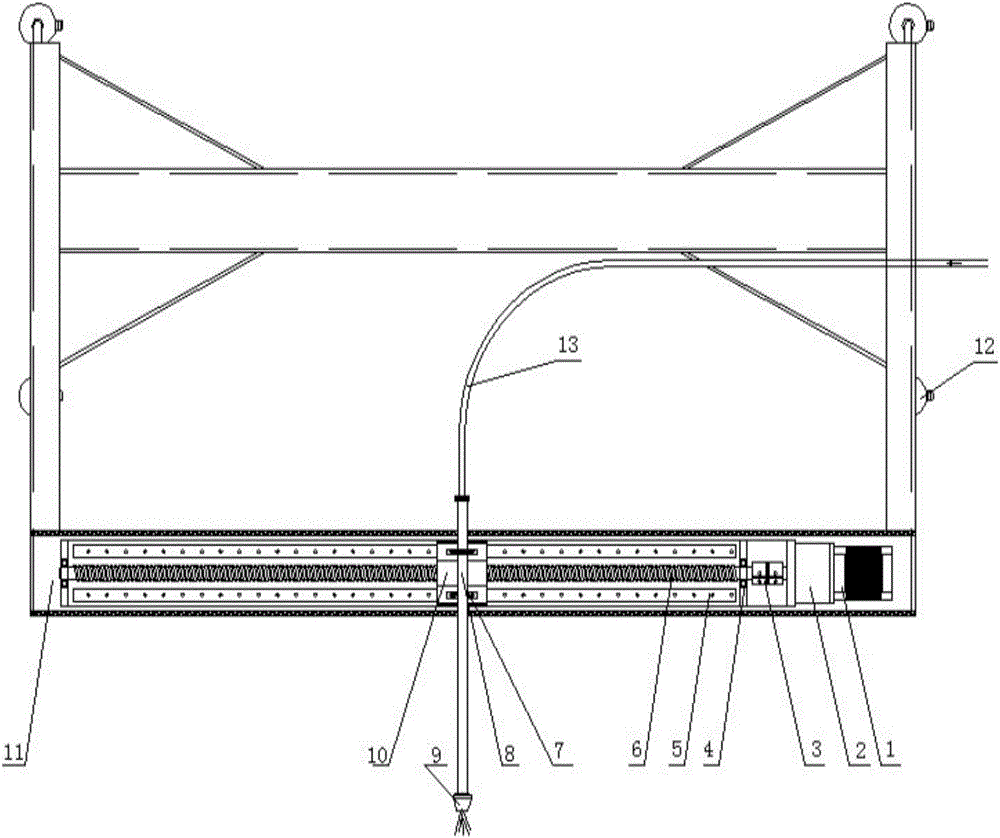

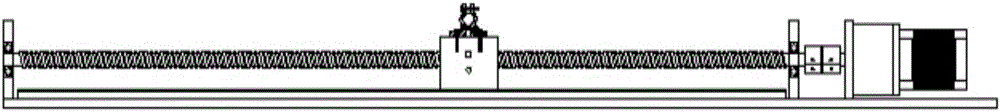

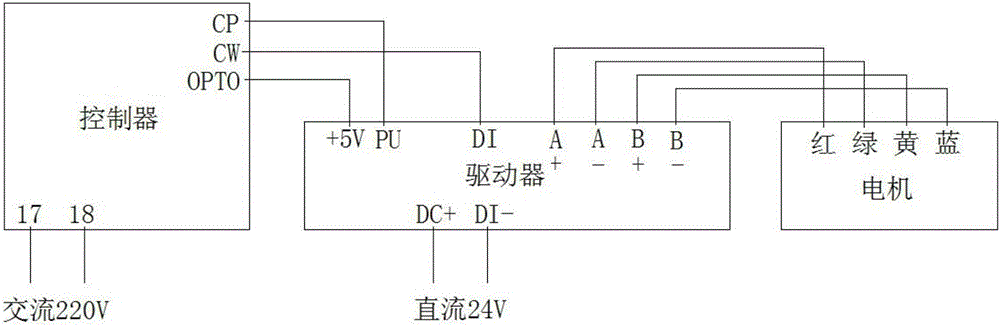

[0028] This embodiment provides a vacuum belt conveyor filter cloth program-controlled flushing device, such as figure 1 , figure 2 As shown, it consists of three parts: program-controlled rail car, high-pressure water gun and electronic control system. The program-controlled rail car includes a slide rail 5 and a guide rail screw 6 parallel to the slide rail 5 , the slide rail 5 and the guide rail screw 6 are fixed on a support 11 , and bearings 4 are sleeved at both ends of the guide rail screw 6 . There is a high-pressure water gun on the program-controlled rail car, which is composed of a nozzle 9, a hard pipe 7 connected to the nozzle 9, and a flexible pipe 13 connected to the rear end of the hard pipe 7. The hard pipe 7 is fixed on the slider 10 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com