Vehicle component maintenance method and impeller cleaning machine

A technology for auto parts and maintenance, applied in vehicle maintenance, vehicle maintenance/repair, chemical instruments and methods, etc., can solve problems such as air pollution, affecting human health, environmental pollution, etc., and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

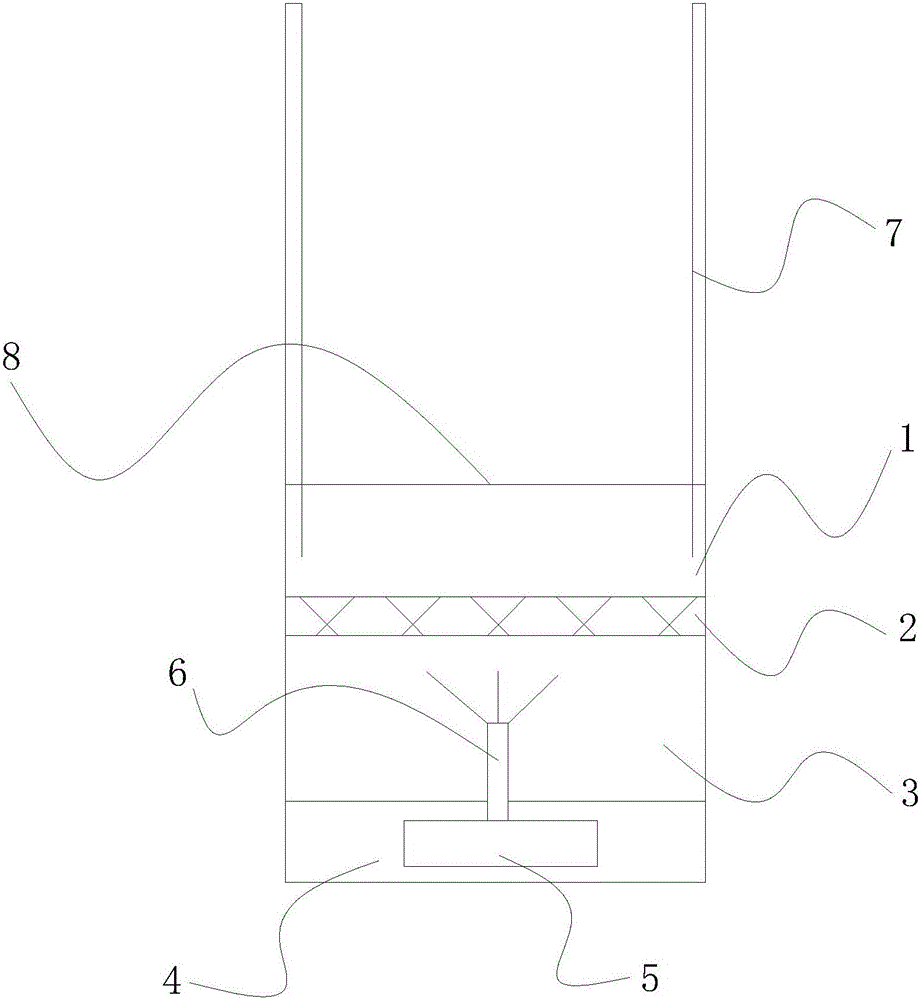

[0075] Embodiment one, a kind of auto parts repair and maintenance method, it comprises the following steps:

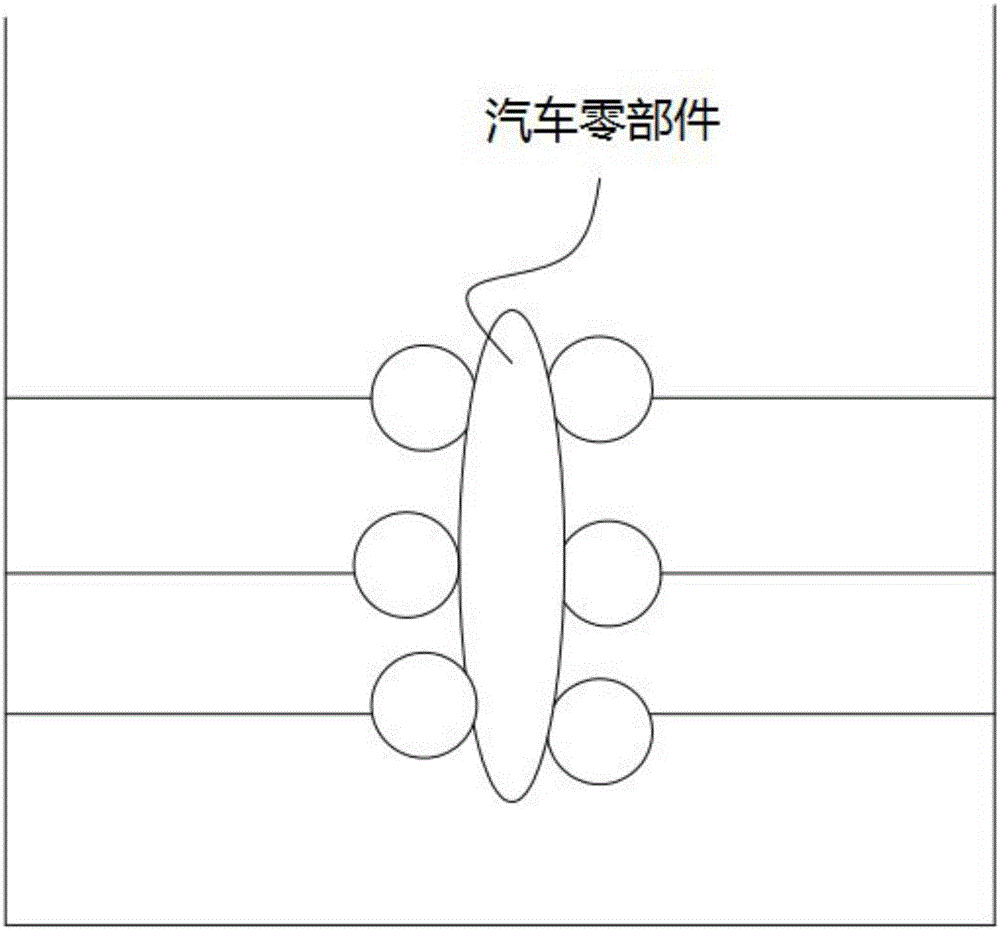

[0076] Dust removal: Fix the auto parts on the bracket, and fix the sides of the auto parts through the suction cups on the bracket; use the vacuum aspirator to vacuum the two sides of the auto parts, and the vacuum aspirator The aperture of the suction port is 50mm, and the distance between the vacuum aspirator and the auto parts is 20mm;

[0077] Clean water infiltration: adjust the pH value of the clean water to 7.5, and control the water temperature at 40°C; soak the auto parts after the dust removal treatment in the above clean water for 2 minutes, and keep the pH value and water temperature of the clean water unchanged;

[0078] Solution preparation: Mix 4 parts of stearic acid monoglyceride, 3 parts of sodium tripolyphosphate, 6 parts of trisodium phosphate, 3 parts of sodium lignosulfonate, 7 parts of sodium citrate, and 200 parts of water according to the wei...

Embodiment 2

[0085] Embodiment two, a kind of auto parts maintenance method, it comprises the following steps:

[0086] Dust removal: Fix the auto parts on the bracket, and fix the two sides of the auto parts through the suction cup on the bracket; use the vacuum aspirator to vacuum the two sides of the auto parts, and the vacuum aspirator The aperture of the suction port is 70mm, and the distance between the vacuum aspirator and the auto parts is 50mm;

[0087] Clean water infiltration: adjust the pH value of the clean water to 7.8, and control the water temperature at 55°C; soak the auto parts after the dust removal treatment in the above clean water for 10 minutes, and keep the pH value and water temperature of the clean water unchanged;

[0088] Solution preparation: Mix 6 parts of stearic acid monoglyceride, 4 parts of sodium tripolyphosphate, 7 parts of trisodium phosphate, 4 parts of sodium lignosulfonate, 9 parts of sodium citrate, and 300 parts of water according to the weight rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com