Retaining ring short-flow manufacturing process

A manufacturing process and short-flow technology, applied to metal processing equipment, etc., can solve the problems of high processing cost, low pass rate, and many forging processes, and achieve the effect of increasing product pass rate, reducing processing cost, and reducing forging processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

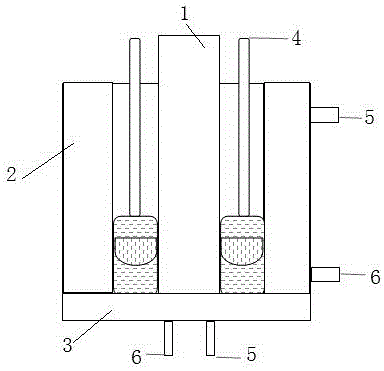

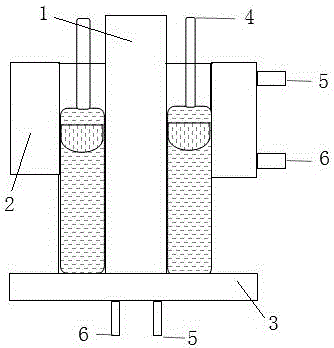

[0023] Attached below figure 1 , 2 The present invention is described in detail:

[0024] A short process manufacturing process for a retaining ring is characterized in that the method comprises the steps of:

[0025] A) Electroslag hollow steel pipe: The production principle of electroslag continuous casting moving mandrel is adopted, that is, the self-consumable electrode 4 is continuously and evenly melted, and the slag surface continues to rise. After reaching the predetermined height, start the dummy device, and pull the hollow steel ingot downward at a slow speed Moving, the casting speed is proportional to the melting speed of the consumable electrode 4. The two reach a balanced state. After the smelting is completed, the steel ingot and the water-cooled mandrel 1 are lifted out, and the water-cooled mandrel 1 is taken out. The hollow steel pipe retaining ring is completed. ;

[0026] Dummy device: water-cooled dummy plate 3

[0027] The outer diameter of the hollow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com