Mixed biological contact oxidation tank

A biological contact and hybrid technology, applied in biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of low aeration efficiency of aeration devices, clogging of sludge and suspended matter, and increased maintenance costs and other problems to achieve the effect of maintaining aeration efficiency, increasing aeration efficiency, and reducing later maintenance costs and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

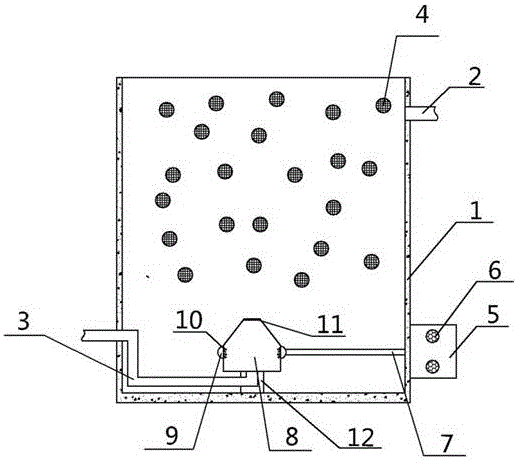

[0020] Such as figure 1 and figure 2 Shown is a preferred solution of the present invention, a hybrid biological contact oxidation tank, including a tank body 1, filler 4 and a hybrid aeration device, the inner bottom of the tank body 1 is provided with a base 12, and is fixed by the base 12 Hybrid aeration device.

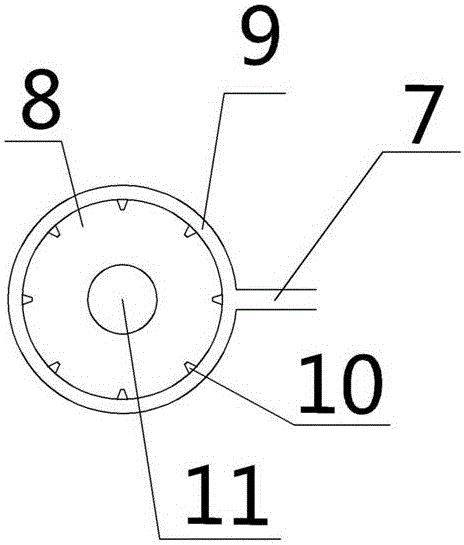

[0021] Further, the hybrid aeration device includes a mixing chamber 8, an annular aeration pipe 9 and a water outlet 11, the outer wall of the mixing chamber 8 is fixed with an annular aeration pipe 9, and the inner ring of the annular aeration pipe 9 is There are eight sets of aeration inclined openings 10 at equal circle center angles on the surface. The aeration inclined openings 10 pass through the outer wall of the mixing chamber 8 and extend into the mixing chamber 8. Each set of aeration inclined openings 10 is provided with four aeration inclined openings 10 in the longitudinal direction. Slope 10, the outer side of the ring-shaped aeration pipe 9 is c...

Embodiment 2

[0023] This embodiment is further optimized on the basis of the above-mentioned embodiment, further to better realize the present invention; the lower part of one side of the outer wall of the pool body 1 is provided with an air compressor 5, and one end of the air inlet pipe 7 is connected to the air compressor 5 Connected, the aeration efficiency is increased by applying a certain wind pressure to the air intake, and the aeration inclined opening 10 is cleaned independently to avoid the situation that the sludge clogs the aeration inclined opening 10 .

Embodiment 3

[0025] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention; the filler 4 is a suspended filler, the specific surface area per unit of the suspended filler is large, the porosity is high, and the material is light and strong. , and can cut bubbles, increase the contact area of the gas-liquid two-phase, and play a certain role in improving the oxygen capacity in water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com