Bottle discharge mechanical hand, bottle manufacturing machine and glass bottles

A technology of manipulator and bottle making machine, applied in manipulator, glass blowing, glass forming, etc., can solve the problems of low stability and reliability, less applicable speed, large space occupied, etc., to achieve mandatory Small, improve space utilization, take up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0046] In order to enable those skilled in the art to better understand the various technical solutions involved in the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments in this application and the specific technical features described in the embodiments can be combined in any suitable way; The possible combinations are not further described, as long as they do not violate the idea of the present invention, they should also be regarded as the content disclosed in the present invention.

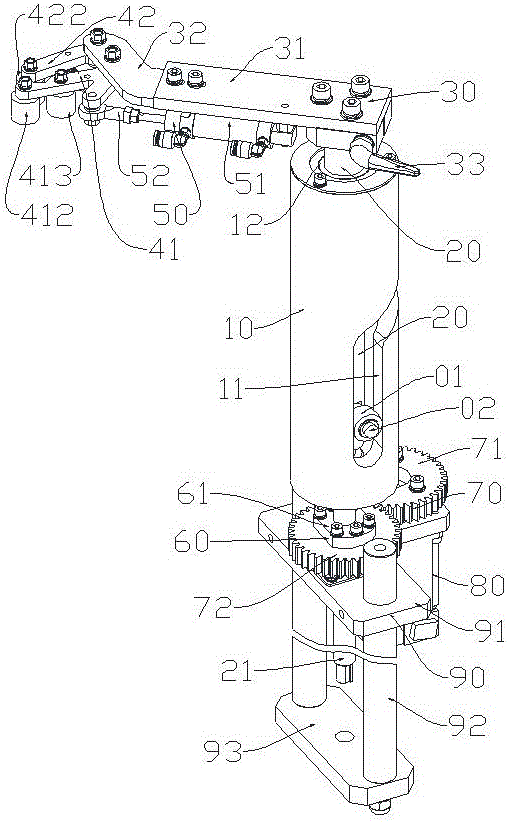

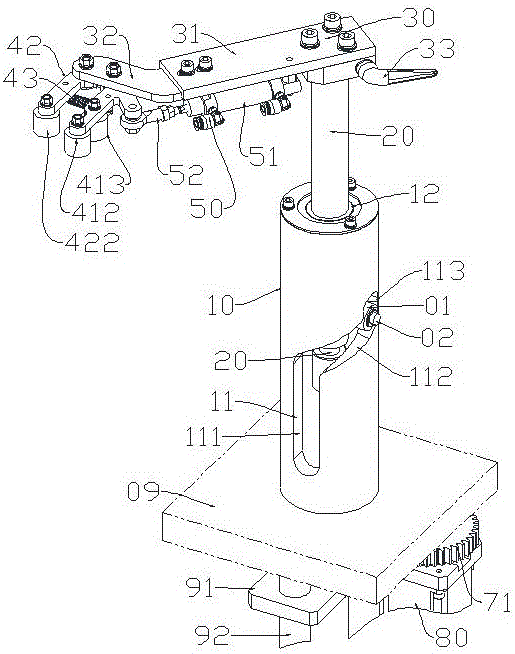

[0047] like figure 1 and figure 2 as shown, figure 1 A three-dimensional schematic view of the bottle-discharging manipulator provided by a specific embodiment of the present invention, showing that the lifting shaft is located at the bottom and the split jaws are in a tensioned state; figure 2 for figure 1 The thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com