Method for preparing positive ion composite modified asphalt

A technology of compound modified asphalt and modified asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve the problem that the high temperature, low temperature and elastic recovery of modified asphalt cannot meet the technical requirements of ultra-thin wear layer and road performance. problems such as poor spraying, flow of spraying amount, etc., to achieve the effect of prolonging the service time of the road surface, improving the strength of the seal layer, and improving the adhesion between the layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below through specific examples.

[0014] A preparation method of cationic composite modified asphalt is carried out according to the following steps:

[0015] Step 1, first heating the asphalt to 60-100°C, adding a surfactant to the asphalt, and stirring for 10-30 minutes to obtain modified asphalt;

[0016] Step 2, heating the water to 40-60°C, then sequentially adding modifier, blending agent and emulsifier into the water, stirring for 5-10 minutes to obtain mixed soap;

[0017] Step 3: Mix the modified asphalt prepared in step 1 and the mixed soap liquid prepared in step 2 and mechanically stir for 30-40 minutes at a stirring temperature of 80-100°C. After stirring evenly, cool down to 20-25°C to obtain a cationic composite modified asphalt. Sexual asphalt.

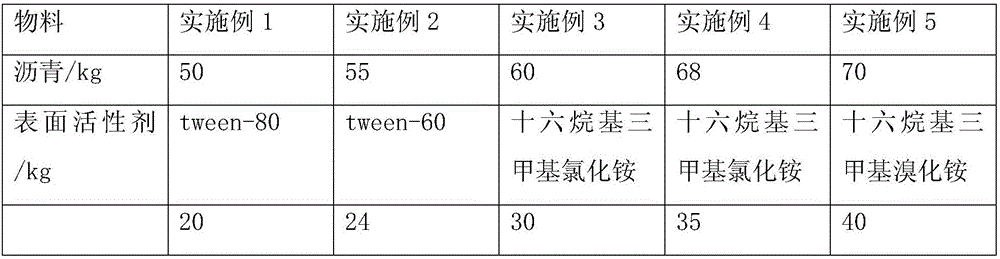

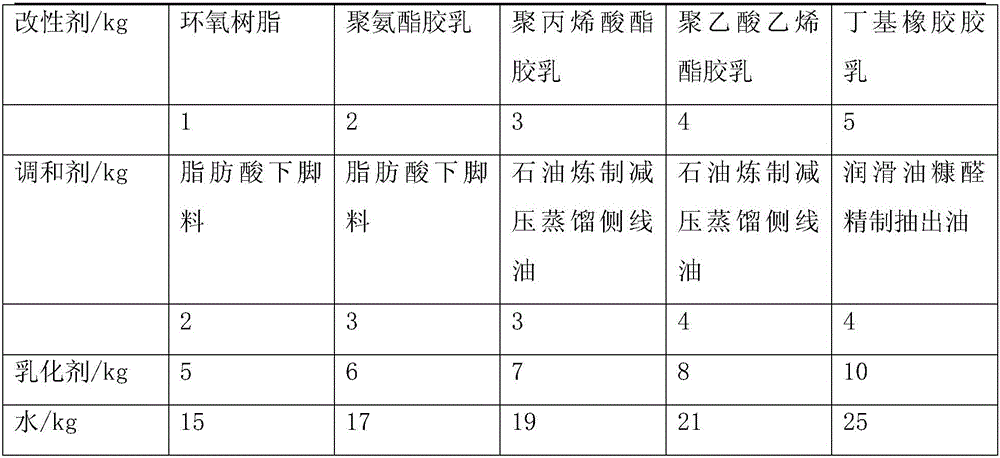

[0018] Material addition is shown in the table below in each embodiment:

[0019]

[0020]

[0021] The plugging of micro-crac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com