Wet paper-plastic pulp fishing system, wet paper-plastic product and method for forming wet paper-plastic product

A technology of wet paper and pulp, applied in the direction of textiles and papermaking, etc., can solve the problems affecting the performance of finished products and the decrease of overall strength, so as to improve the product yield and avoid bridging phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions of the various embodiments refer to the drawings to illustrate specific embodiments in which the present invention can be implemented. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are for reference only The direction of the schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

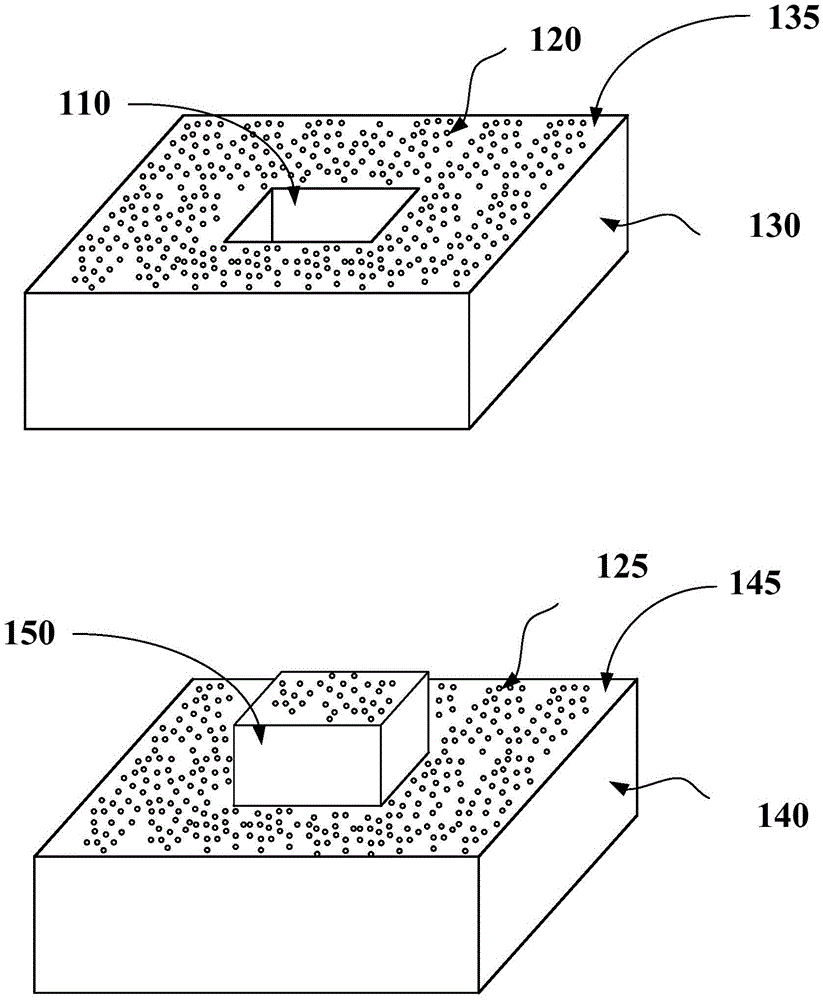

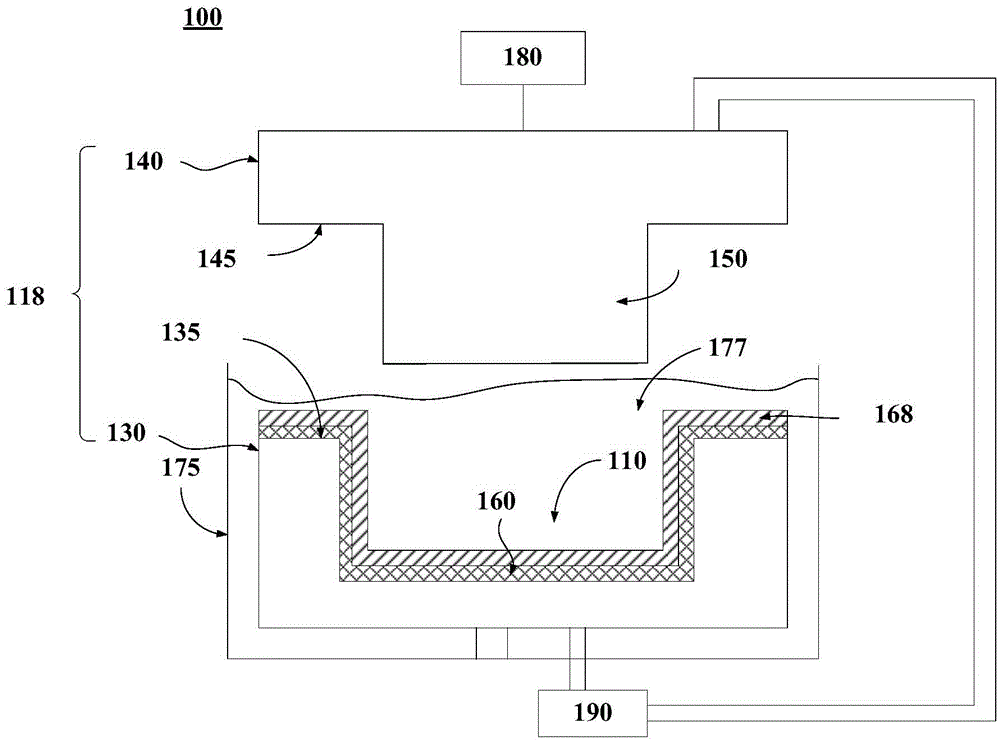

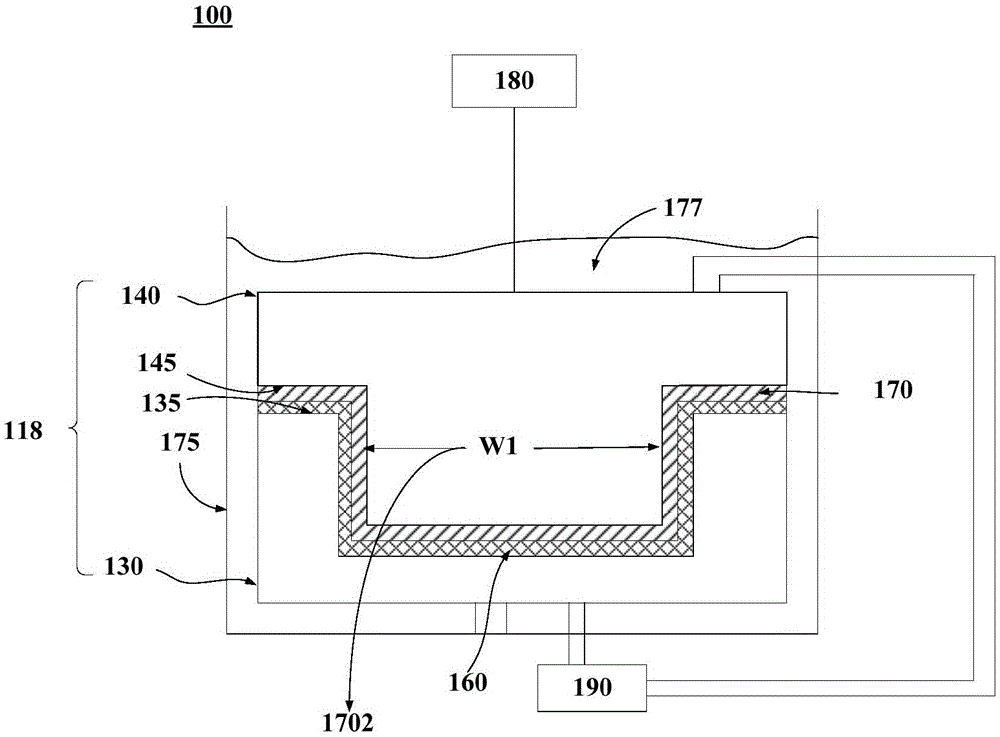

[0034] refer to figure 1 and figure 2 . figure 1 , depicts a three-dimensional schematic view of the mold assembly of the wet paper plastic pulping system 100 according to the present invention. figure 2 , is a schematic cross-sectional view of the mold assembly of the wet paper plastic pulping system 100 according to the present invention before mold closing. The wet pulp extraction system 100 includes a pulp tank 175 , a mold assembly 118 , an extension device 180 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com