A construction method for synchronous flipping of a double-deck vault storage tank

A construction method and an inversion technology, which is applied in the field of synchronous inversion construction of double-layer vault storage tanks, can solve the problems of the impact of finished storage tank product protection, large impact on project progress, and difficulty in product protection, so as to improve the quality of finished products. The effect of protecting quality, improving safety factor, and reducing the amount of secondary installation and dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

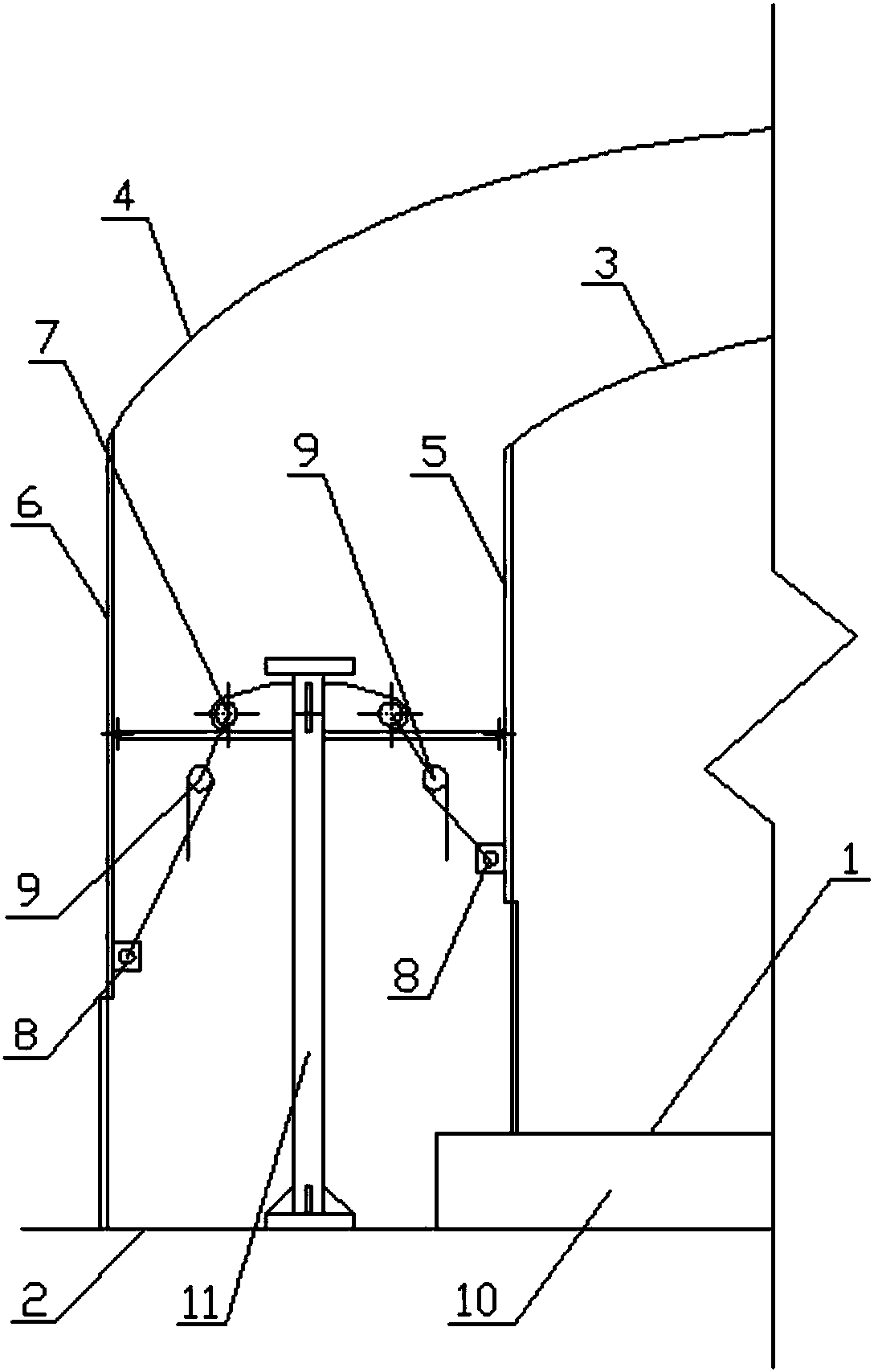

[0028] Hereinafter, the present invention will be further explained through the description of the embodiments in conjunction with the drawings:

[0029] Such as figure 1 As shown, a synchronous inverted construction method for a double-arch roof storage tank of the present invention includes the construction of the inner tank bottom plate 1, the outer tank bottom plate 2, the construction of the inner tank top plate 3, the outer tank top plate 4, and the inner tank wall plate 5. The construction of the outer tank wall 6 includes the following steps:

[0030] 1), blanking, prefabricated storage tank inner tank bottom plate 1, outer tank bottom plate 2, inner tank top plate 3, outer tank top plate 4, inner tank wall plate 5, outer tank wall plate 6 and parts;

[0031] 2). Assemble the outer tank bottom plate 2 first, then construct the cold insulation layer 10 between the inner tank bottom plate 1, the outer tank bottom plate 2, and then assemble the inner tank bottom plate 1; Draw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com