Forced idling lubrication system of hydraulic retarder

A hydraulic retarder and forced lubrication technology, which is applied in the direction of liquid resistance brakes, lubricating parts, engine lubrication, etc., can solve the problems of complex hydraulic oil circuit system, high manufacturing precision and cost, and large installation size, etc., to achieve High safety and reliability, convenient use and maintenance, and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

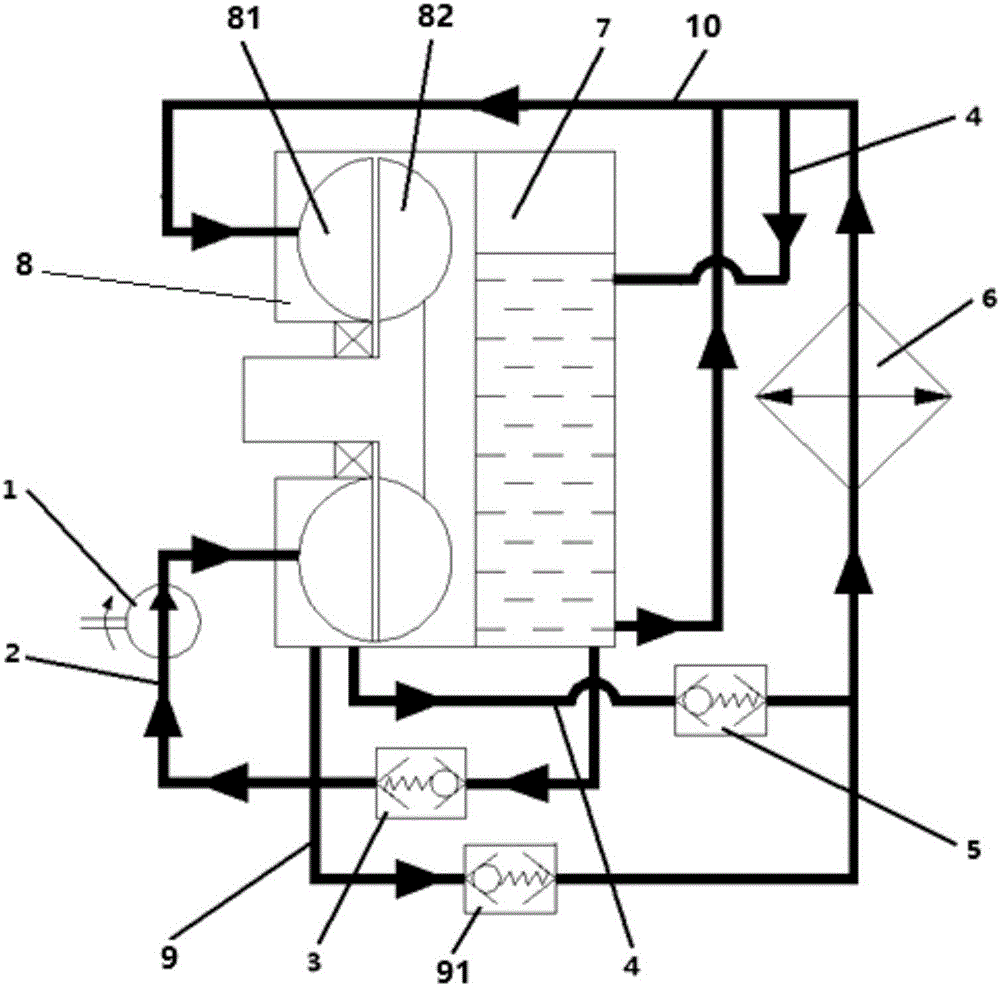

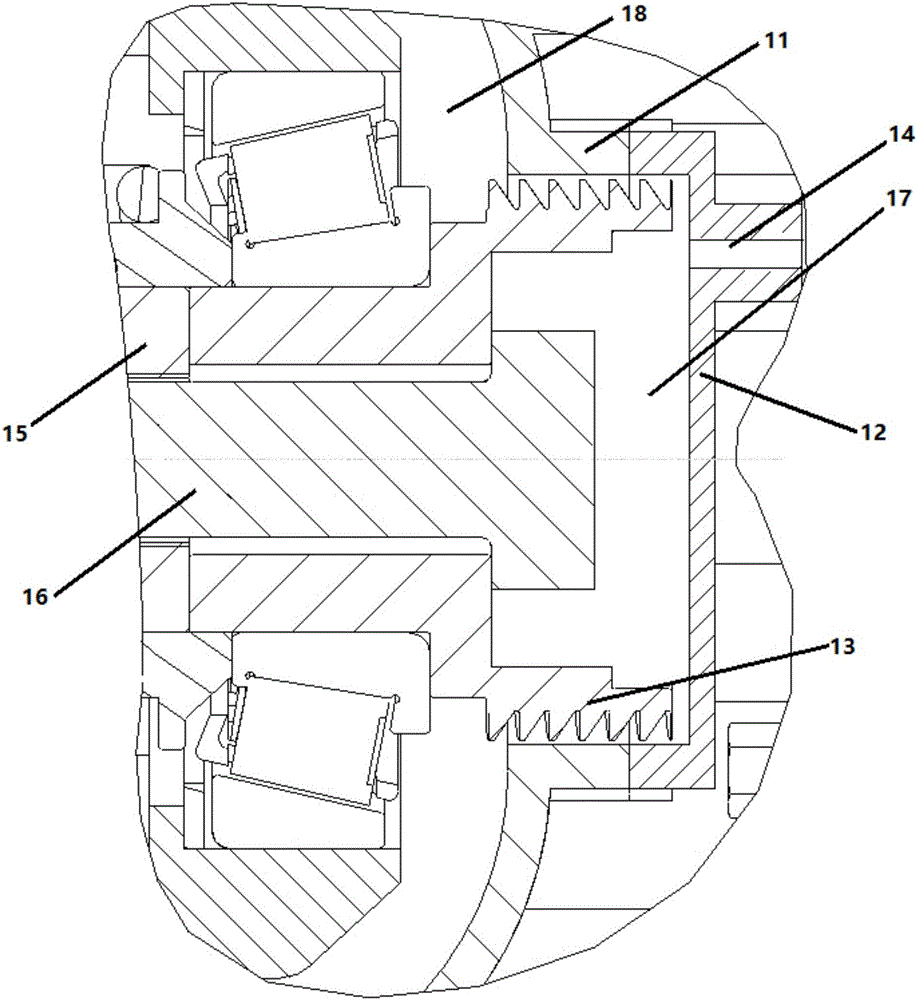

[0019] The present invention adopts a novel threaded pump as the hydraulic retarder idling lubrication system of the oil pumping element, such as figure 1 As shown, it consists of a threaded pump 1, a lubricating circulation oil inlet passage 2, a lubricating circulation oil inlet check valve 3, a lubricating circulation oil outlet passage 4, a lubricating circulation oil outlet check valve 5, a heat exchanger 6 and The oil pool consists of 7. The retarder 8 is provided with a working cycle oil outlet circuit 9 and a working cycle oil inlet circuit 10; when working, the oil enters the heat exchanger 6 from the retarder 8 through the working cycle oil outlet check valve 91 Flow into the oil pool 7 or directly into the working cycle oil inlet 10, so that the cooled oil enters the retarder 8 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com