A high-speed ball screw pair double nut pretightening force control device and method

A ball screw pair and control device technology, which is applied in the direction of measuring devices, instruments, machine gear/transmission mechanism testing, etc., can solve the problems of large environmental factors, inconvenient installation, high cost, etc., and achieve strong feasibility and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

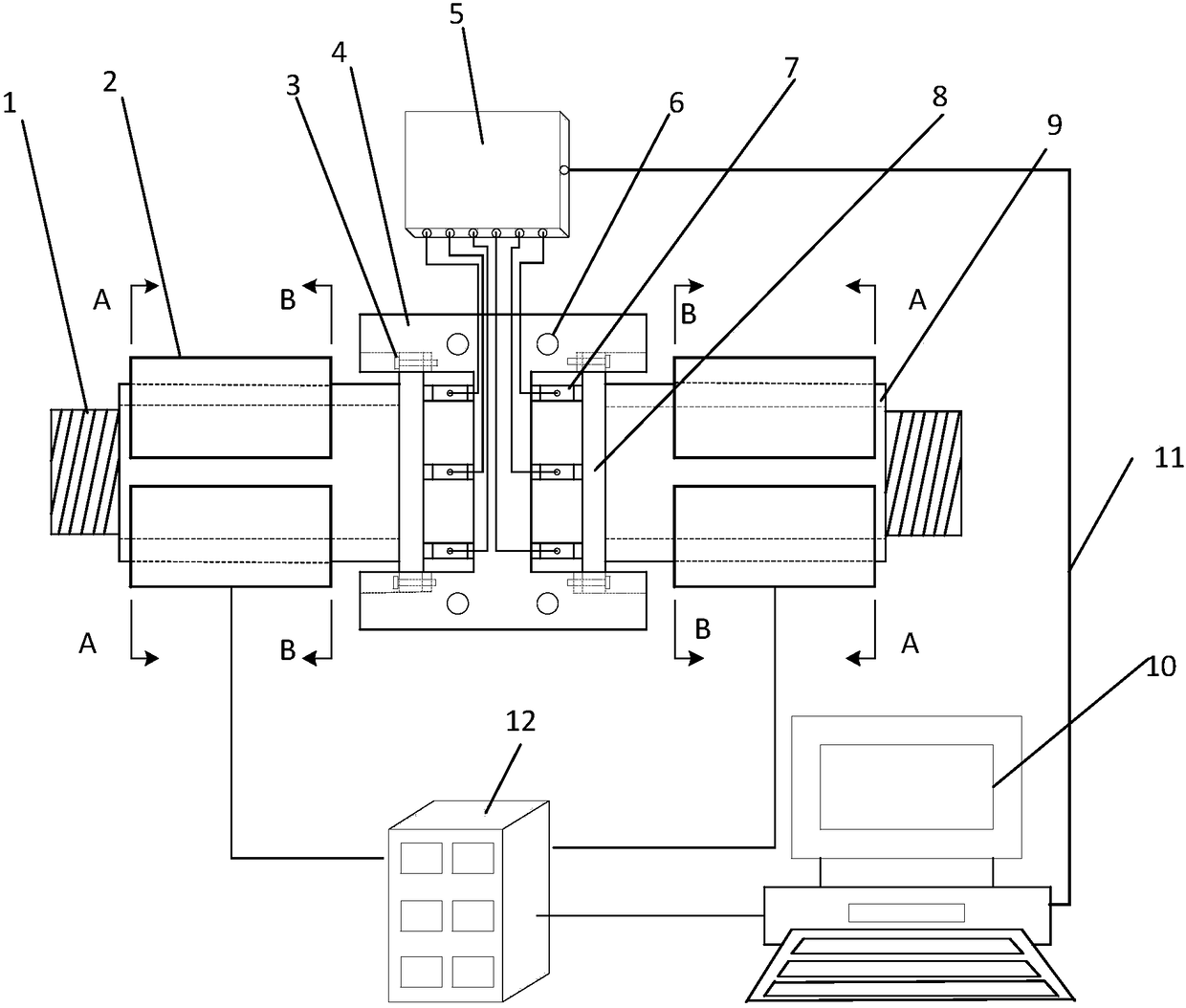

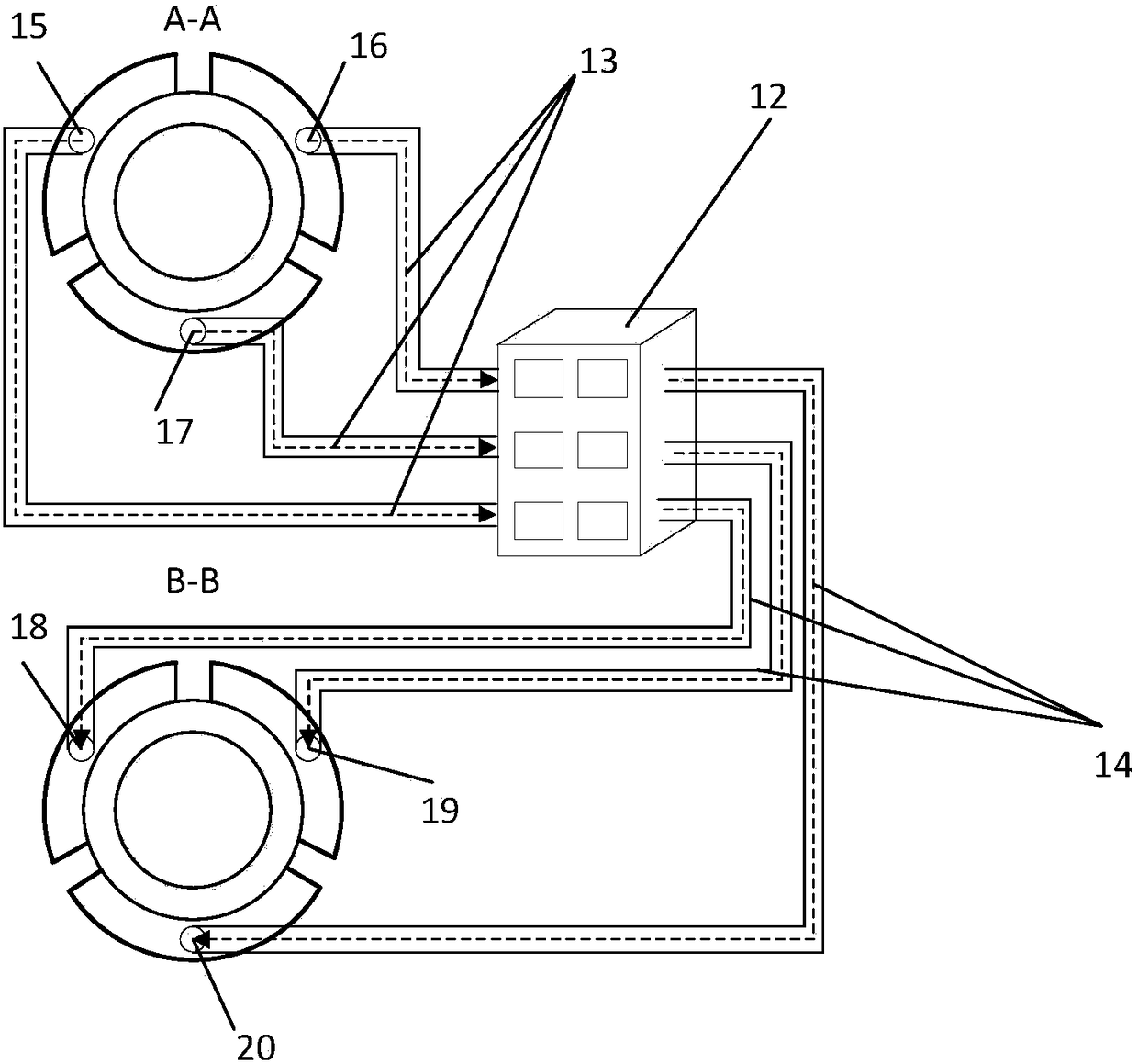

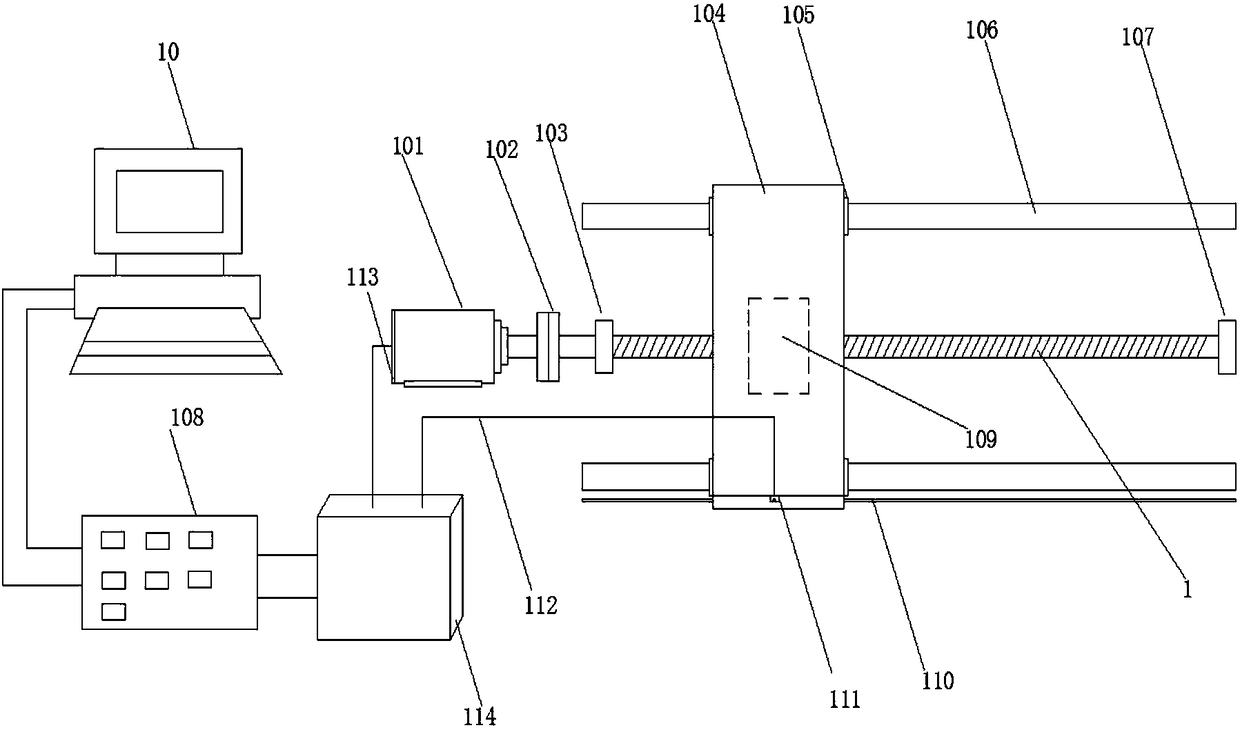

[0043] The invention provides a high-speed ball screw pair double nut pretightening force control device, the structure of which is as follows: figure 1 As shown, it includes a lead screw 1 and a pair of nuts 9 respectively arranged on the lead screw 1. The outer circumference of the pair of nuts 9 is distributed with a fan-shaped cavity 2 connected to the temperature control system 12; the inner ends of the pair of nuts are respectively provided with nuts The preload end 8 is provided with a work piece 4 between a pair of nut preload ends 8, and the work piece 4 is provided with a fine-tuning screw rod 3 for adjusting the preload force of a pair of nut preload ends 8; A pressure sensor 7 is arranged between the end 8 and the workpiece 4, the pressure sensor 7 is connected to the acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com