Method for obtaining low-rank coal pyrolysis characteristic parameters and semi-coke combustion characteristic parameters

A technology of characteristic parameters and combustion characteristics, which is applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that characteristic parameters cannot be effectively compared and analyzed, and the temperature control system requires high precision and poor accuracy. Achieve the effect of research specification, accurate parameters and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

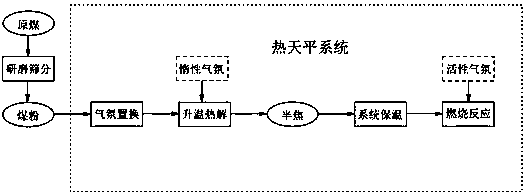

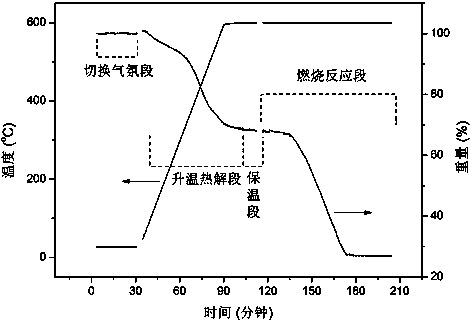

[0045] 1) Grind and sieve the Shenmu lignite raw coal to 160-200 mesh to obtain coal powder;

[0046] 2) Weigh 25 mg of the coal powder obtained in step 1) into a thermobalance crucible, and under the protection of an Ar atmosphere with a flow rate of 100 ml / min, perform atmosphere replacement in the thermobalance at room temperature;

[0047] 3) Continue to heat the sample to 600°C at a heating rate of 10°C / min under the protection of an Ar atmosphere with a flow rate of 100 ml / min to obtain coal semi-coke, and the thermobalance system automatically records the coal during the pyrolysis process. powder weight change data, and obtain the weight time change curve and temperature time change curve of the coal powder;

[0048] 4) Insulate at 600°C for 10 minutes;

[0049] 5) Switch the Ar atmosphere to air atmosphere, carry out semi-coke combustion at 600°C in a heat preservation state, and the thermobalance system automatically records the weight change data of the coal semi-co...

Embodiment 2

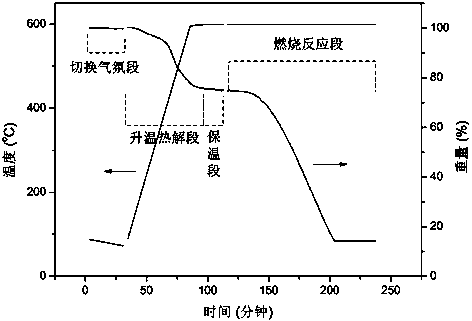

[0052] 1) Grind and sieve Shenmu bituminous coal to 160-200 mesh to obtain coal powder;

[0053] 2) Weigh 25 mg of the coal powder obtained in step 1) into a thermobalance crucible, and under the protection of an Ar atmosphere with a flow rate of 100 ml / min, perform atmosphere replacement in the thermobalance at room temperature;

[0054] 3) Continue to heat the sample to 600°C at a heating rate of 10°C / min under the protection of an Ar atmosphere with a flow rate of 100 ml / min to obtain coal semi-coke, and the thermobalance system automatically records the coal during the pyrolysis process. powder weight change data, and obtain the weight time change curve and temperature time change curve of the coal powder;

[0055] 4) Insulate at 600°C for 10 minutes;

[0056] 5) Switch the Ar atmosphere to air atmosphere, carry out semi-coke combustion at 600°C in a heat preservation state, and the thermobalance system automatically records the weight change data of the coal semi-coke, a...

Embodiment 3

[0059] 1) Grind and sieve the Shenmu lignite raw coal to 160-200 mesh to obtain coal powder;

[0060] 2) Weigh 25 mg of the coal powder obtained in step 1) into a thermobalance crucible, and under the protection of an Ar atmosphere with a flow rate of 100 ml / min, perform atmosphere replacement in the thermobalance at room temperature;

[0061] 3) Continue to heat the sample to 600°C at a heating rate of 10°C / min under the protection of an Ar atmosphere with a flow rate of 100 ml / min to obtain coal semi-coke, and the thermobalance system automatically records the coal during the pyrolysis process. powder weight change data, and obtain the weight time change curve and temperature time change curve of the coal powder;

[0062] 4) Insulate at 600°C for 10 minutes;

[0063] 5) Switch the Ar atmosphere to include 21% O 2 + 79% CO 2 Combustion of semi-coke in a mixed atmosphere at 600°C, the thermobalance system automatically records the weight change data of the coal semi-coke, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com