A Method for Reducing the Difference Between Head and Tail Properties of Electroslag Steel Ingots

A steel ingot and electroslag technology, which is applied to the performance difference between the head and tail of the electroslag steel ingot, reduces the performance difference between the head and tail of the electroslag steel ingot, can solve the problems that the blade and bolt materials are difficult to meet the use requirements, and achieve good economic benefits and social benefits. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

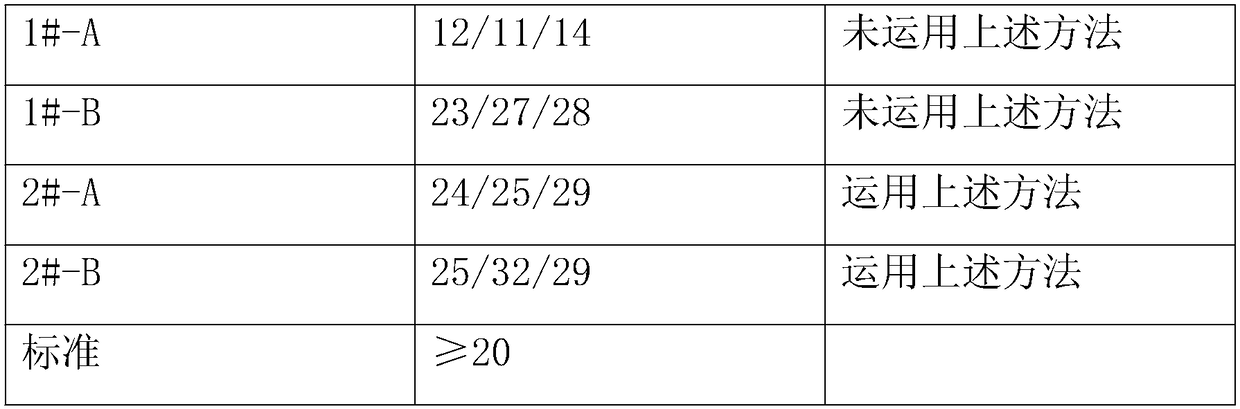

Embodiment 1

[0018] A method for reducing the head-to-tail performance difference of an electroslag steel ingot, the specific steps are as follows:

[0019] Step A, sedating and cooling the steel ingot melt for a period of time greater than 8 minutes;

[0020] Step B, casting the molten steel ingot after being killed in step A, and casting at about 40°C above the theoretical liquidus temperature of the corresponding steel grade;

[0021] Step C, deoxidizing the steel ingot cast in step B: adding a deoxidizer to the feeding end of the steel ingot for deoxidation treatment, the amount of deoxidizer added in the deoxidation treatment process in step C is the amount added to the bottom end of the steel ingot Increase 0.02~0.04 / Wt%;

[0022] Step D, homogenizing the steel ingot deoxidized in step C;

[0023] In step E, the steel ingot processed in step D is forged, and a 2000T press is used for forging, and an intermediate billet is forged by a two-upsetting and two-drawing process.

[0024]...

Embodiment 2

[0030] A method for reducing the head-to-tail performance difference of an electroslag steel ingot, the specific steps are as follows:

[0031] Step A, sedating and cooling the steel ingot melt for a period of time greater than 8 minutes;

[0032] Step B, casting the molten steel ingot after being killed in step A, and casting at about 50° C. above the theoretical liquidus temperature of the corresponding steel grade;

[0033] Step C, deoxidizing the steel ingot cast in step B: adding a deoxidizer to the feeding end of the steel ingot for deoxidation treatment, the amount of deoxidizer added in the deoxidation treatment process in step C is the amount added to the bottom end of the steel ingot Increase 0.02~0.04 / Wt%;

[0034] Step D, homogenizing the steel ingot deoxidized in step C;

[0035] In step E, the steel ingot processed in step D is forged, and a 2000T press is used for forging, and an intermediate billet is forged by a two-upsetting and two-drawing process.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com