A processing method for high-precision stepped deep-hole parts

A processing method and high-precision technology, applied in the field of deep hole boring processing of mechanical parts, can solve problems such as poor straightness, inability to guarantee size and shape accuracy, etc., and achieve convenient operation, reasonable and reliable processing method, and high processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

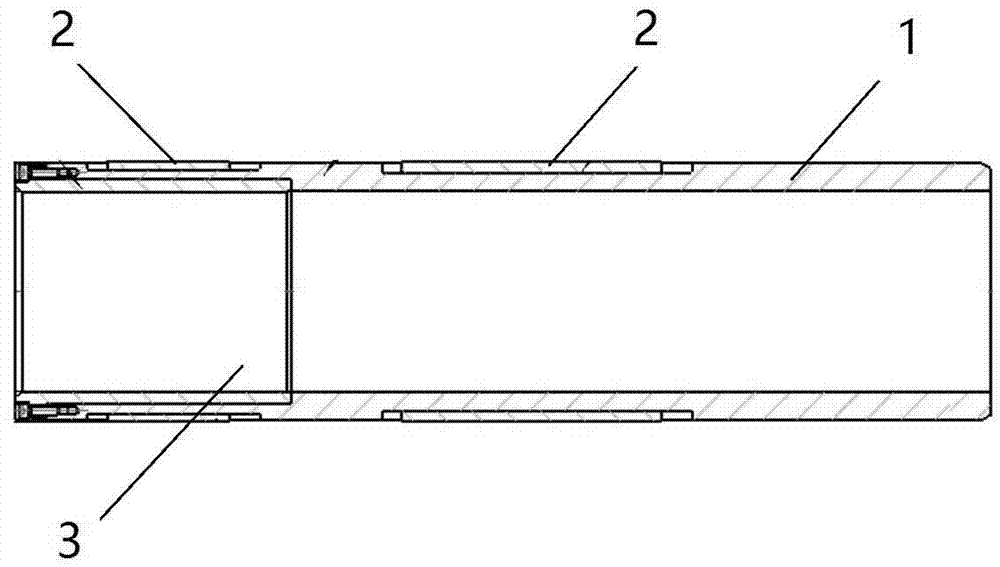

[0010] A method for processing high-precision stepped deep-hole parts, the following steps are adopted: a. Dividing the deep-hole parts into a part body I and a part body II according to the size of the aperture; b. Machining the inner hole of the part body I until the hole is formed, Leave the machining allowance for the outer circle, then process the inner hole and the outer circle of the part body II and leave the machining allowance respectively, and then assemble and weld with the part body I; c. After welding, press a plug into the outer end hole of the part body II, and then Drill the center hole on the outer end face of the plug, process the outer circle of the part body I and the part body II with the inner hole of the part body I and the center hole of the part body II to the finished product size; d, make the guide cylinder, the guide cylinder includes cylinder body 1, cylinder body 1 The outer wall is provided with several rectangular grooves, and the wooden support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com