Auxiliary electric rear axle of front-drive vehicle

A rear axle and vehicle technology, which is applied to vehicle components, electric power units, power units, etc., can solve the problems of insufficient traction of front-drive vehicles, and achieve the effects of small parasitic power loss, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

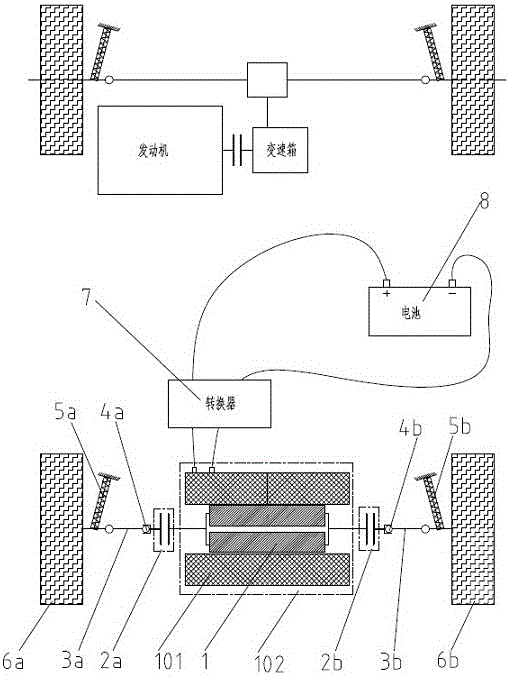

[0019] combined with figure 1 , specific embodiment 1 is described:

[0020] The auxiliary electric rear axle of the front-drive vehicle according to the present invention is composed of a main drive motor 1, a rear axle transmission clutch group 2, a half shaft 3, a universal joint 4, a suspension 5, a driving wheel 6, a battery converter 7 and a battery 8 .

[0021] Rear axle transmission clutch group 2 is composed of left clutch (2a) and right clutch (2b), half shaft 3 is composed of left half shaft (3a) and right half shaft (3b), universal joint 4 is composed of left universal joint (4a ) and the right universal joint (4b).

[0022] The main drive motor 1 is composed of an excitation coil 101 and a rotor 102. In order to realize the recovery of braking energy during the running of the vehicle, the main drive motor adopts the coaxial configuration of the rotor 102 and the left half shaft 3a and the right half shaft 3b. The main drive motor 1 The power is related to the ...

Embodiment 2

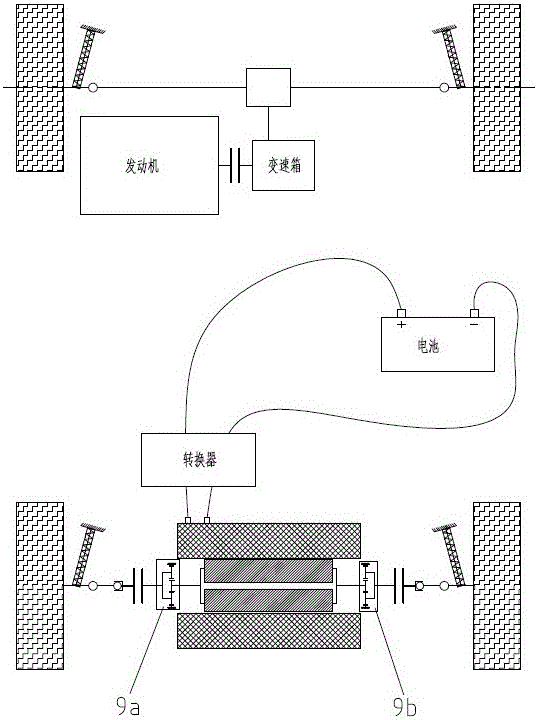

[0030] combined with figure 2 , the specific embodiment 2 is described: on the basis of embodiment 1, in order to further improve the load characteristics of the main drive motor 1, the rear axle transmission clutch set 2 is connected with the main drive motor 1 through a reducer 9. Reducer 9 adopts a planetary gear mechanism, that is, a planetary gear reducer, which can keep the coaxial connection of rear axle transmission clutch group 2 and main drive motor 1 .

Embodiment 3

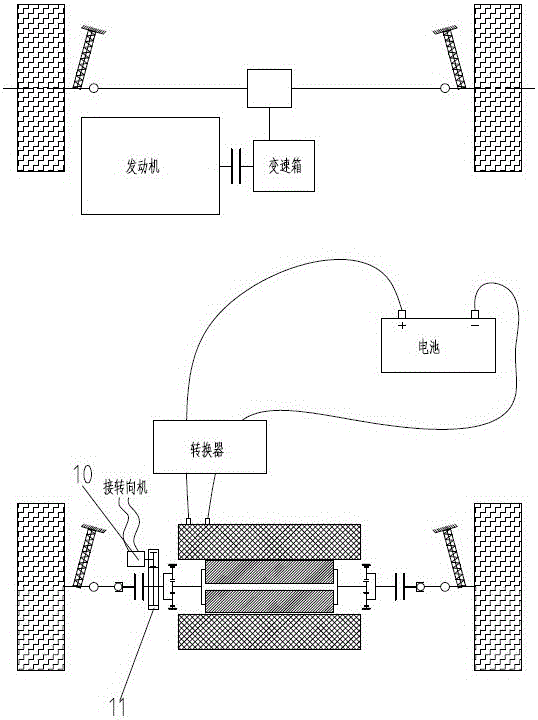

[0032] combined with image 3 , to illustrate the specific embodiment 3: in the state of engine flameout, in order to ensure that the off-road vehicle can be driven purely by the main drive motor 1, on the basis of the specific embodiment 2, install between the left reducer 9a and the left clutch 2a Transfer case 11, the transfer case 11 has a structure of an input shaft and two output shafts, the output shaft 1 of the transfer case 11 is connected with the left clutch 2a, and the output shaft 2 of the transfer case 11 is connected with the hydraulic pump 10.

[0033] Working principle: When the fuel of the off-road vehicle is exhausted, the engine cannot be started. At this time, the battery 9 supplies power to the main drive motor 1 to drive the vehicle. At the same time, the main drive motor 1 drives the hydraulic pump 12 through the transfer case 11 to provide hydraulic oil to the steering system. , to ensure the normal operation of the steering system of off-road vehicles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com