High-quality blended alcohol-based fuel, preparation method and application thereof

A high-quality, alcohol-mixed technology, applied in fuels, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of increased hourly C emissions, achieve the effects of reducing activation energy of spontaneous combustion, saving fuel, and improving ignition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

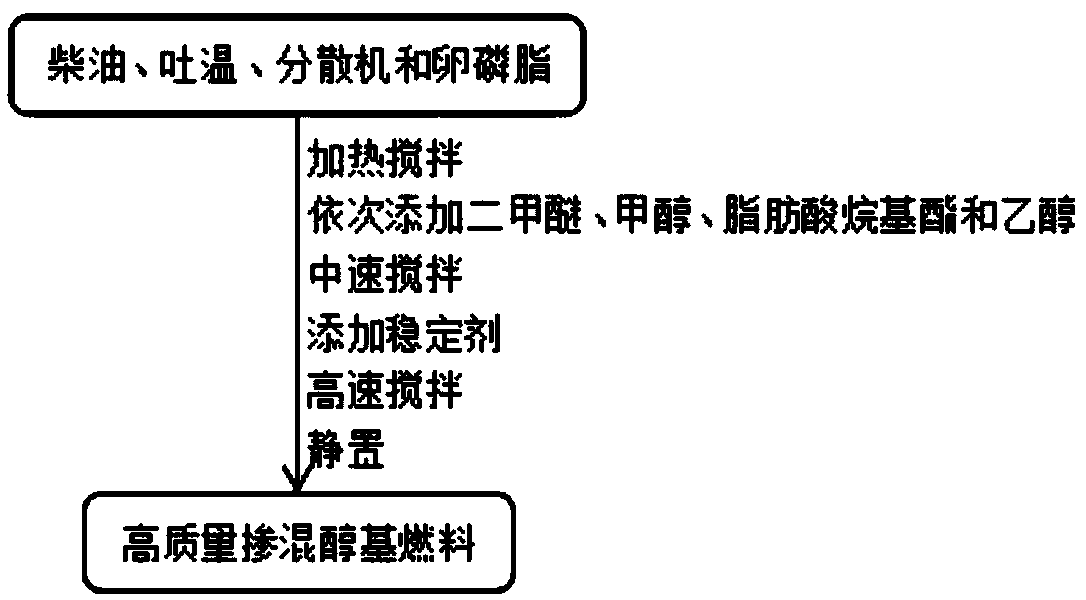

Method used

Image

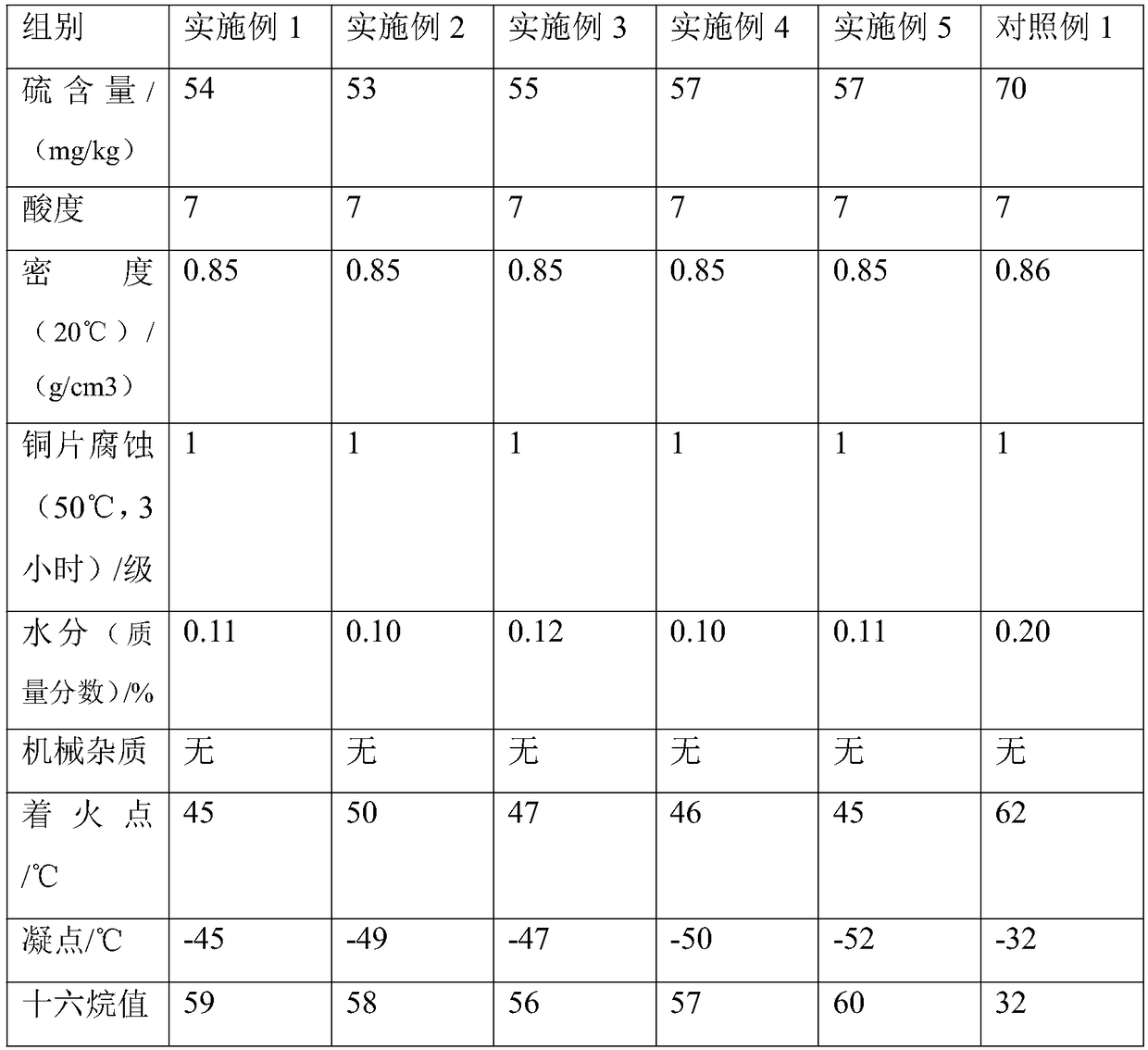

Examples

Embodiment 1

[0053] The preparation of embodiment 1 high-quality blended alcohol-based fuel

[0054] Raw material composition:

[0055] 10 parts of methanol;

[0056] 20 parts of ethanol;

[0057] 5 parts of dimethyl ether;

[0058] 60 parts of crude oil distillation diesel;

[0059] 10 parts of fatty acid alkyl ester;

[0060] 1 part of compound cetyl improver;

[0061] Tween 0.5 part;

[0062] 1 part lecithin;

[0063] 2 parts of liquid paraffin;

[0064] Octylphenol polyoxyethylene ether OP-101 parts.

[0065] The compound cetyl improver is compounded by weight ratio: 2-methylhexyl carbonate: isooctyl carbonate: n-nonyl phosphate=5:1:0.5.

[0066] Prepare according to the following method: weigh each raw material in proportion, mix crude oil distilled diesel oil, Tween, liquid paraffin and lecithin, heat to 40°C, stir evenly, add dimethyl ether, methanol, fatty acid alkyl ester and ethanol in sequence, Stir at medium speed (200 rpm) for 4 hours, after mixing evenly, continue to ...

Embodiment 2

[0067] The preparation of embodiment 2 high-quality blended alcohol-based fuels

[0068] Raw material composition:

[0069] 30 parts of methanol;

[0070] 30 parts of ethanol;

[0071] 25 parts of dimethyl ether;

[0072] 80 parts of petroleum coking diesel oil;

[0073] 20 parts of fatty acid alkyl ester;

[0074] Compound cetyl improver 5 parts;

[0075] Tween 3.5 parts;

[0076] Lecithin 3 parts;

[0077] 7 parts of microcrystalline paraffin;

[0078] Octylphenol polyoxyethylene ether OP-46 parts.

[0079] The compound cetyl improver is compounded by weight ratio: 2-methylhexyl carbonate: isooctyl carbonate: n-nonyl phosphate = 15:5:2.5.

[0080] Prepare according to the following method: weigh each raw material in proportion, mix petroleum coker diesel oil, Tween, microcrystalline paraffin and lecithin, heat to 50°C, stir evenly, add dimethyl ether, methanol, fatty acid alkyl ester and ethanol in sequence , stirring at a medium speed (300 rpm) for 7 hours, after ...

Embodiment 3

[0081] The preparation of embodiment 3 high-quality blended alcohol-based fuels

[0082] Raw material composition:

[0083] 15 parts of methanol;

[0084] 22 parts of ethanol;

[0085] 15 parts of dimethyl ether;

[0086] 65 parts of hydrocracked diesel oil;

[0087] 12 parts of fatty acid alkyl ester;

[0088] 2 parts of compound cetyl improver;

[0089] 1 part Tween;

[0090] Lecithin 1.5 parts;

[0091] 4004 parts of polyethylene glycol;

[0092] Fatty alcohol polyoxyethylene ether AEO-52 parts.

[0093] The compound cetyl improver is compounded by weight ratio: 2-methylhexyl carbonate: isooctyl carbonate: n-nonyl phosphate = 7:2:1.

[0094] Prepare according to the following method: Weigh each raw material in proportion, mix hydrocracked diesel oil, Tween, polyethylene glycol 400 and lecithin, heat to 45°C, stir well, add dimethyl ether, methanol, fatty acid alkyl in sequence Ester and ethanol, stir at medium speed (250 rpm) for 5 hours, after mixing evenly, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com