Exhaust pipe for reducing soot content

A technology of soot and carbon content and exhaust pipes, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., can solve problems such as poor connection strength, insufficient space, and high noise, and achieve pollution reduction, beautiful appearance, and long-term use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

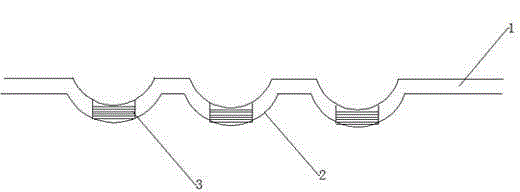

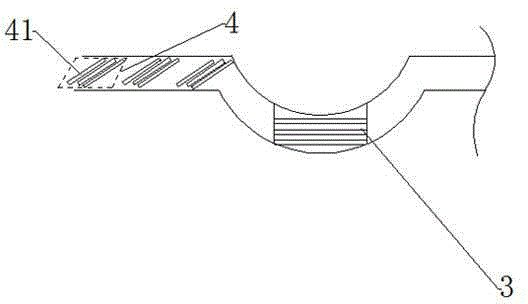

[0021] The invention relates to an exhaust pipe for reducing the content of soot and charcoal, comprising an exhaust pipe body 1 made of metal, such as figure 1 As shown: three discontinuous U-shaped structures 2 are arranged on the exhaust pipe body 1, and each U-shaped structure 2 includes a soot filter device 3;

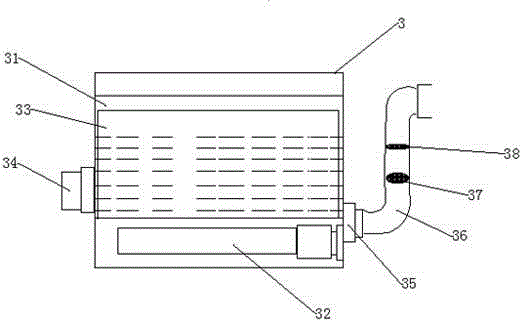

[0022] Specifically, such as figure 2 As shown: the smoke charcoal filtering device 3 includes a filter chamber 31, and the filter chamber 31 is provided with an automatic water supply tank 33 and an automatic water supply program control device 32 arranged in the automatic water supply tank 33, and an automatic water supply program control device 32 arranged on one side of the automatic water supply tank 33 Exhaust gas inlet 34 and the tail gas outlet 35 that are arranged on the other side of automatic water supply tank 33; The air port 35 is 5cm lower in height. The exhaust pipe of this embodiment can finely filter the exhaust gas of the motor vehicle in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com