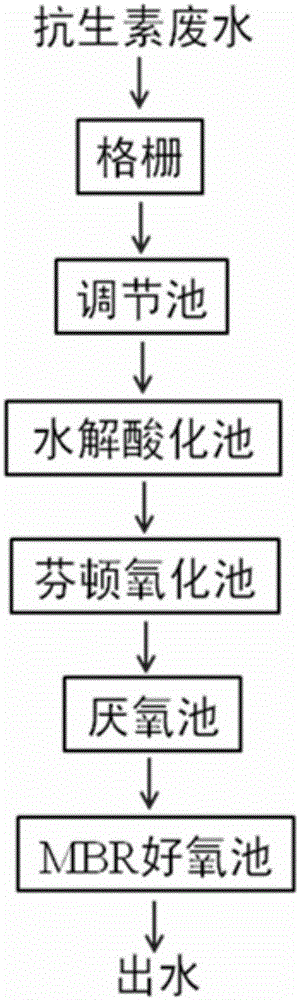

Method for advanced treatment of antibiotic waste water by combination of Fenton oxidation and MBR

A technology of antibiotic wastewater and Fenton oxidation, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, aerobic and anaerobic process treatment, etc. , cost cost, the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

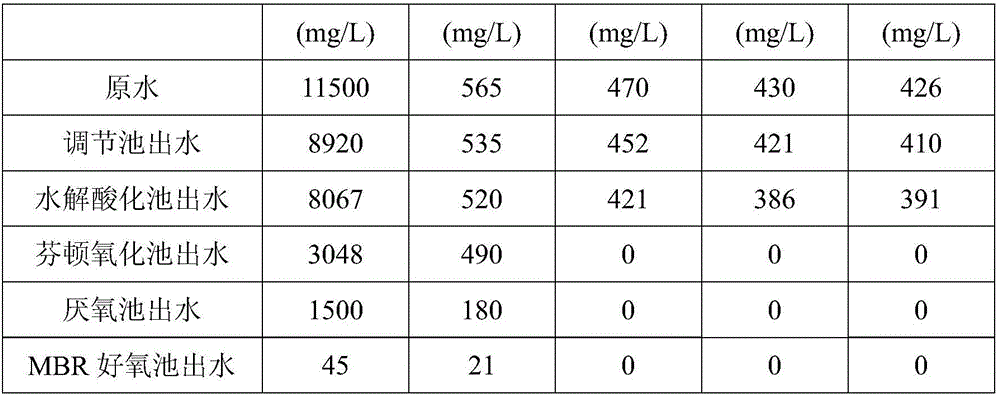

Embodiment 1

[0025] Taking the waste water of an antibiotic pharmaceutical company as an example, the waste water is successively processed through the grille, regulating tank, hydrolytic acidification tank, Fenton oxidation tank, anaerobic tank and MBR aerobic tank. The polyaluminium chloride of wastewater in the regulating tank is 30mg / L, the polyacrylamide is 5mg / L, and the hydraulic retention time is 2h; the hydraulic retention time of wastewater in the hydrolytic acidification tank is 36h, and the pH value is 6.0; the wastewater is oxidized in Fenton pH in the pool is 2.0, Fe 2+ 10mg / L, H 2 o 2 The pH of wastewater in the anaerobic tank is 6.8, the dissolved oxygen is 0.2mg / L, and the hydraulic retention time is 36h; the pH of wastewater in the MBR aerobic tank is 6.5, and the dissolved oxygen is 2mg / L, the hydraulic retention time is 32h, the membrane adopts polyvinylidene fluoride hollow fiber membrane, and the membrane flux is 20L / (m 2 h), the membrane pore size is 0.1μm, and t...

Embodiment 2

[0030] Taking the waste water of an antibiotic pharmaceutical company as an example, the waste water is successively processed through the grille, regulating tank, hydrolytic acidification tank, Fenton oxidation tank, anaerobic tank and MBR aerobic tank. The polyaluminium chloride of wastewater in the regulating tank is 40mg / L, the polyacrylamide is 8mg / L, and the hydraulic retention time is 5h; the hydraulic retention time of wastewater in the hydrolytic acidification tank is 24h, and the pH value is 6.0; the wastewater is oxidized in Fenton pH in the pool is 4.0, Fe 2+ 20mg / L, H 2 o 2 The pH of the wastewater in the anaerobic tank is 6.8, the dissolved oxygen is 0.1mg / L, and the hydraulic retention time is 24h; the pH of the wastewater in the MBR aerobic tank is 6.5, and the dissolved oxygen is 4mg / L, the hydraulic retention time is 24h, the membrane adopts polyvinylidene fluoride hollow fiber membrane, and the membrane flux is 40L / (m 2 h), the membrane pore size is 0.3μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com