Novel environment-friendly waterborne textile coating polyfoam

A technology of textile coating and styrofoam, which is applied in the fields of textiles, papermaking, fiber treatment, etc., can solve problems such as increased product yield, imperfect styrofoam compounding, and reduced textile quality stability, etc., to achieve good results. The effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

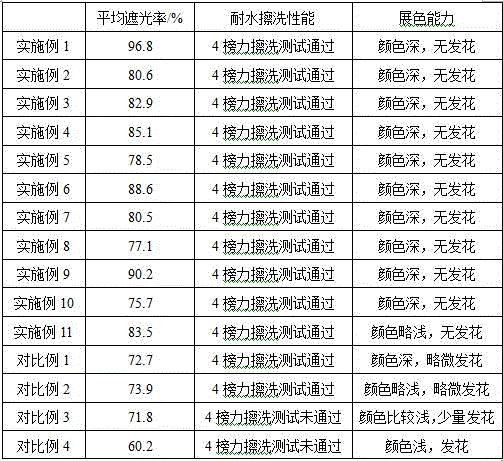

Examples

Embodiment 1

[0058] Preparation method of coating foam:

[0059] 1) Put the water-based acrylate emulsion into the reaction kettle with a stirring device, and start stirring at a slow speed to obtain the mixture A.

[0060] 2) Add ammonium stearate additive, TiO 2 Titanium white slurry, stir evenly to obtain mixture B, wherein ammonium stearate and TiO 2 It needs high-speed dispersion of dispersant and ultra-fine treatment by turbo sand mill.

[0061] 3) Finally, add preservatives, antifungal agents, thickeners, and leveling agents to the mixture B obtained in step 2) in sequence. Stir well and filter to get the finished product.

[0062] The coating adhesive formula for blackout curtain fabric is as follows:

[0063] Water-based polyacrylate 100 parts

[0064] 20 parts of ammonium stearate solution

[0065] TiO 2 20 copies

[0066] 15 parts black paste

[0067] 2 parts of N-(2-benzoimidazolyl)-methyl carbamate

[0068] 2-Methyl-4-isothiazolin-3-one 2 parts

[0069] Polyether p...

Embodiment 2

[0073] The preparation method of the coated styrofoam is the same as in Example 1.

[0074] The coating adhesive formula for blackout curtain fabric is as follows:

[0075] Water-based polyacrylate 100 parts

[0076] 20 parts of ammonium stearate solution

[0077] TiO 2 20 copies

[0078] 15 parts black paste

[0079] 2 parts of N-(2-benzoimidazolyl)-methyl carbamate

[0080] 5-Chloro-2-methyl-4-isothiazolin-3-one 2 parts

[0081] Polyether polyurethane-carbitol 5 parts

[0082] Associative water-based PU emulsion 5 parts

[0083] 2 parts ammonia water

Embodiment 3

[0085] The preparation method of the coated styrofoam is the same as in Example 1.

[0086] The coating adhesive formula for blackout curtain fabric is as follows:

[0087] Water-based polyacrylate 100 parts

[0088] 20 parts of ammonium stearate solution

[0089] TiO 2 20 copies

[0090] 15 parts black paste

[0091] Tetramethylthiuram disulfide 2 parts

[0092] 5-Chloro-2-methyl-4-isothiazolin-3-one 2 parts

[0093] Polyether polyurethane-carbitol 5 parts

[0094] Associative water-based PU emulsion 5 parts

[0095] 2 parts ammonia water

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com