Water-based fabric coating finishing agent with thermal insulation performance

A technology of coating finishing and finishing agent, applied in fiber processing, textile and papermaking, fiber type, etc., can solve the problems of complex thermal fabric technology, insufficient environmental protection of coating finishing agent, poor thermal insulation effect, etc., and achieve long-term storage stability properties, reducing VOC emissions, and improving heat retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

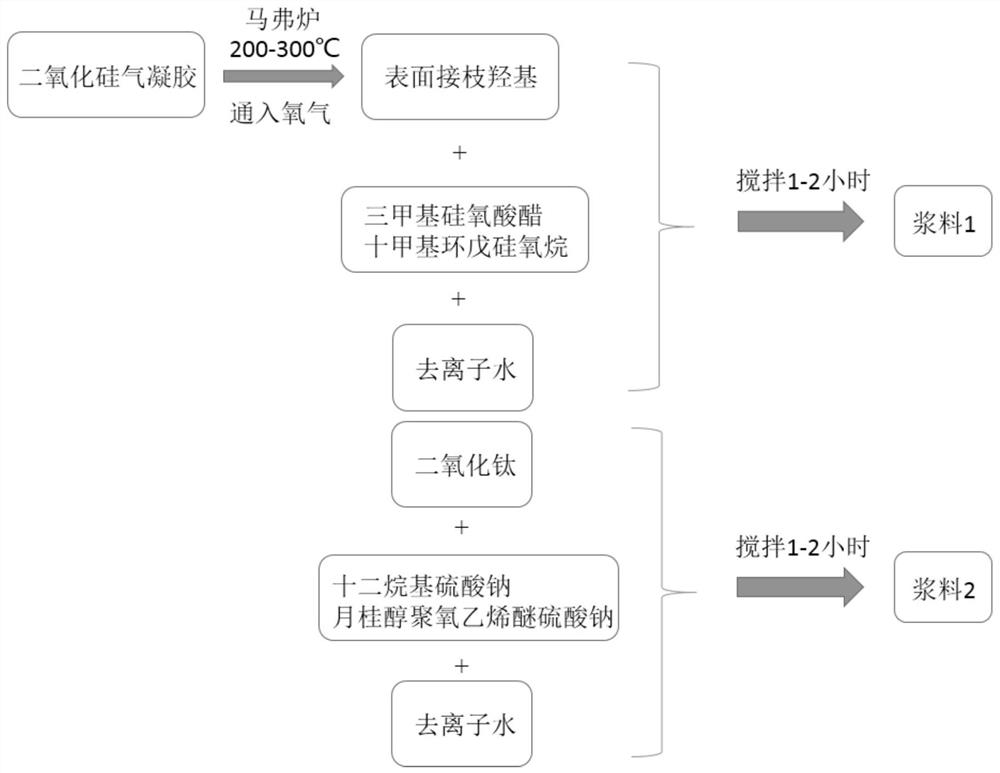

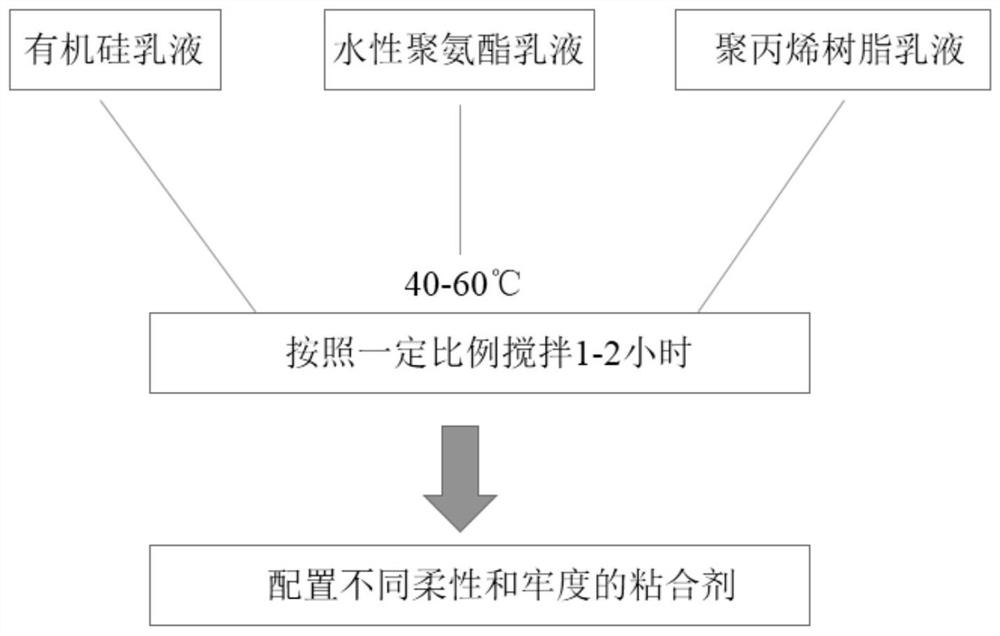

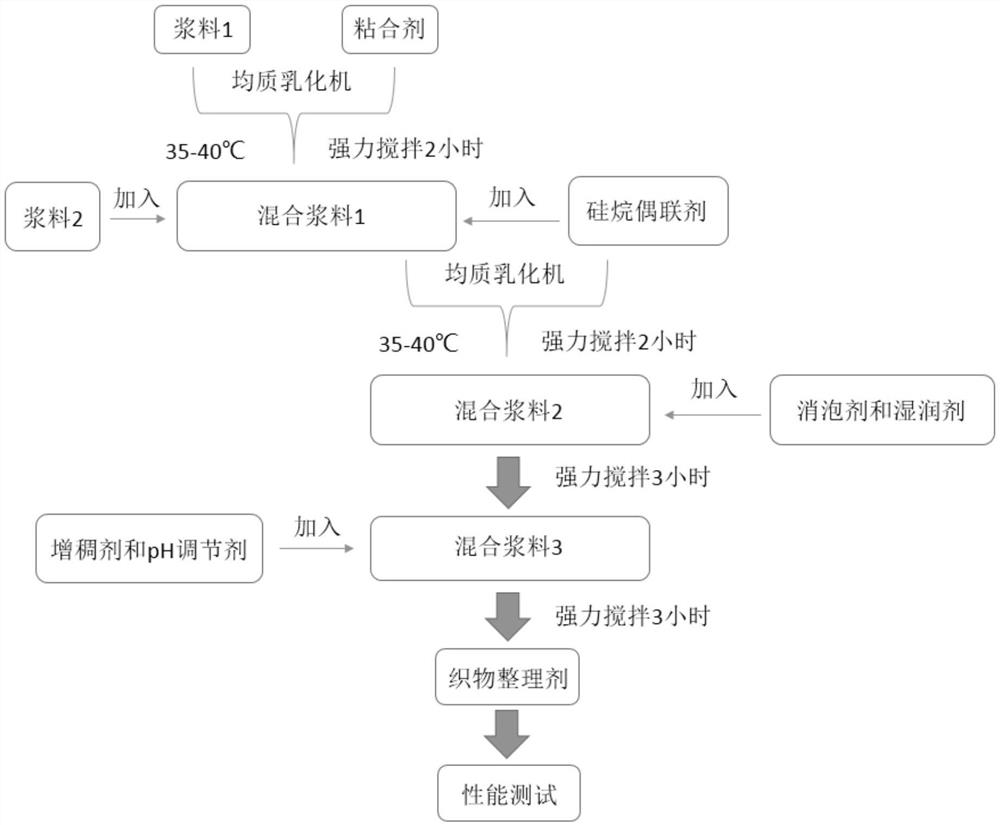

[0056] A water-based fabric coating finishing agent with thermal performance, comprising the following components by weight: 40 parts of water-based polyurethane emulsion (solid content 45%), 10 parts of polypropylene resin emulsion, 4 parts of hydroxyethyl cellulose, deionized 30 parts of water, 6 parts of silicone emulsion, 8 parts of titanium dioxide, 10 parts of surface-treated silica airgel powder, 3 parts of sodium lauryl sulfate, 0.3 parts of sodium lauryl polyoxyethylene ether sulfate, three 2 parts of methyl siloxane, 2 parts of decamethylcyclopentasiloxane, 3 parts of silane coupling agent KH-550, 0.5 part of sorbitan fatty acid ester, 0.5 part of Tween, pH regulator AMP -950.3 parts, 6 parts of defoamer CF-16. Wherein the surface-treated silica airgel is as follows: the muffle furnace is passed through oxygen at a temperature of 200° C. for 5 minutes to graft hydroxyl groups on the surface of the silica airgel.

[0057] A preparation method of a water-based fabric co...

Embodiment 2

[0065] A water-based fabric coating finishing agent with thermal performance, comprising the following components by weight: 50 parts of water-based polyurethane emulsion (solid content 45%), 10 parts of polypropylene resin emulsion, 5 parts of hydroxyethyl cellulose, deionized 35 parts of water, 8 parts of silicone emulsion, 9 parts of titanium dioxide, 15 parts of surface-treated silica airgel powder, 4 parts of sodium lauryl sulfate, 0.4 parts of sodium lauryl polyoxyethylene ether sulfate, three 3 parts of methyl siloxane, 3 parts of decamethylcyclopentasiloxane, 4 parts of silane coupling agent KH-550, 0.4 parts of pH regulator AMP-95, 6 parts of defoamer CF-16, dehydration 0.5 part of sorbitol fatty acid ester, 0.5 part of Tween. Wherein the surface-treated silica airgel is as follows: the muffle furnace is passed through oxygen at a temperature of 200° C. for 5 minutes to graft hydroxyl groups on the surface of the silica airgel.

[0066] This embodiment also provides ...

Embodiment 3

[0068] A water-based fabric coating finishing agent with heat-retaining performance, comprising the following components by weight: 60 parts of water-based polyurethane emulsion (solid content 45%), 20 parts of polypropylene resin emulsion, 6 parts of hydroxyethyl cellulose, deionized 40 parts of water, 10 parts of silicone emulsion, 10 parts of titanium dioxide, 20 parts of surface-treated silica airgel powder, 5 parts of sodium lauryl sulfate, 0.3 parts of sodium lauryl polyoxyethylene ether sulfate, three 4 parts of methyl siloxane, 4 parts of decamethylcyclopentasiloxane, 5 parts of silane coupling agent KH-550, 0.5 parts of pH regulator AMP-95, 8 parts of defoamer CF-16, dehydration 1 part of sorbitol fatty acid ester, 1 part of Tween. Wherein the surface-treated silica airgel is as follows: the muffle furnace is passed through oxygen at a temperature of 300° C. for 5 minutes to graft hydroxyl groups on the surface of the silica airgel.

[0069] This embodiment also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com