High-solid, low-viscosity, high-temperature cooking-resistant polyurethane adhesive composition and preparation method thereof

A polyurethane adhesive, high-solid low-viscosity technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of high viscosity and low solid content, and achieve low viscosity and solid content. High, good printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0025] Preparation Example 1 (A sample) of high-solid, low-viscosity, high-temperature cooking-resistant polyurethane adhesive:

[0026] Synthesize a high-solid, low-viscosity high-temperature cooking-resistant polyurethane adhesive according to the following raw material formula and preparation method.

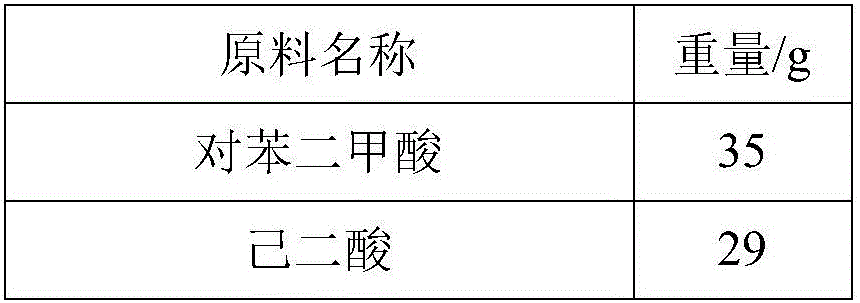

[0027] The formula is:

[0028] raw material name

Weight / g

30

26

15

23

20

Toluene diisocyanate

8

Epoxy resin HyPox UA10

9

coupling agent

1.5

[0029] The preparation method steps are as follows:

[0030] ①Esterification process:

[0031] Add the polybasic acid and polyol into the reaction kettle, raise the temperature to 220°C, react for 2.5 hours, and the esterification is completed;

[0032] ② Polycondensation process:

[0033] Vacuumize the polymerization kettle after the above-mentioned...

Embodiment 2

[0040] Preparation Example 1 (B sample) of high-solid and low-viscosity high-temperature cooking-resistant polyurethane adhesive:

[0041] Synthesize a high-solid, low-viscosity high-temperature cooking-resistant polyurethane adhesive according to the following raw material formula and preparation method.

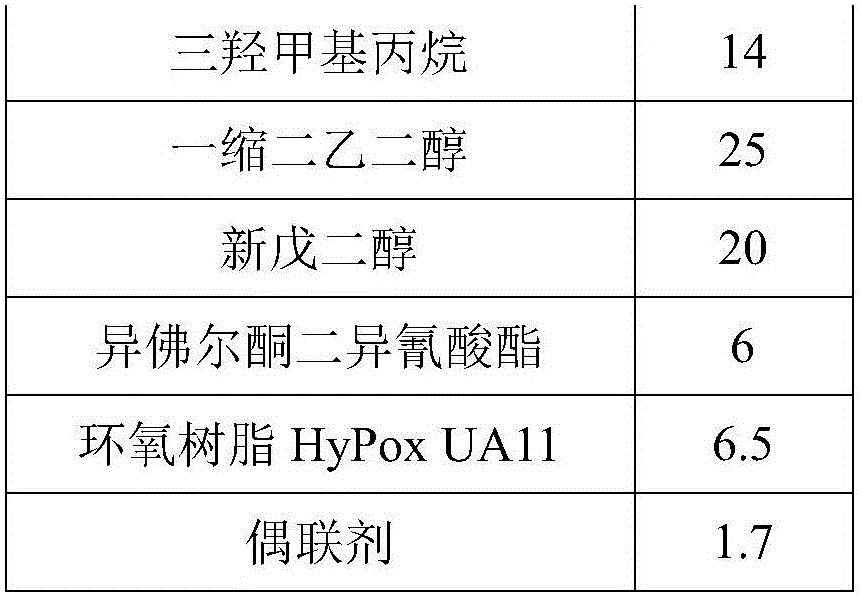

[0042] The formula is:

[0043] raw material name

[0044] Put terephthalic acid, sebacic acid, trimethylolpropane, diethylene glycol, neopentyl glycol and catalysts into a device with heating and stirring in proportion, pass in nitrogen protection, stir to raise the temperature, and control the distillation Head temperature and reaction temperature, complete esterification after reaction. Afterwards, the reaction kettle is vacuumed, and the temperature of the reaction kettle is controlled between 240 and 260°C during vacuuming. Under the condition of vacuuming, the polycondensation reaction of acid and alcohol is completed to obtain hydroxyl-terminated polyester...

preparation Embodiment 2

[0046] Preparation Example 2 (C sample) of high-solid and low-viscosity high-temperature cooking-resistant polyurethane adhesive:

[0047] raw material name

[0048] The steps of the preparation method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com